One goal of any business is to be profitable. It is difficult to assess the profitability of a business without reasonable estimates of income over expenses.

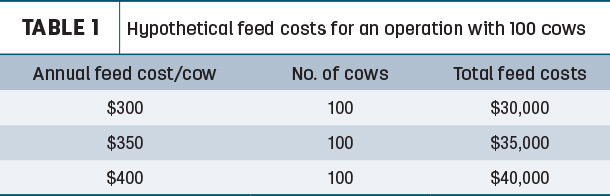

More specifically, if costs aren’t accurately captured at all or are underestimated, it’s hard to tell if a year was actually profitable. For example, missing feed costs by $50 per head (Table 1) could be the difference between profit or loss.

This is less than 20 extra days of winter feed cost, and this is where budgets and planning on historical averages becomes extremely important. Going through daily operations without a plan or goal is the beginning of the end.

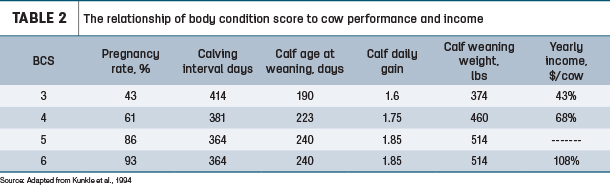

The two biggest operating expenses on a cow-calf operation are feed resources (including land) and herd replacements. Many times these two things can be interconnected, particularly if cows get too thin prior to the breeding season. Allowing cows to fall behind one body condition score prior to calving can significantly reduce pregnancy rates, thus drastically increasing your replacement cost. Cows without adequate body condition at the time of breeding are less likely to become pregnant (Table 2), and the end result could be culling a formerly productive cow.

This culling expense can be easily avoided by good nutrition management, but it takes aligning your forage base with a cow’s nutrient requirements in a comprehensive nutrition program, which may require the input of a professional.

This is where these two expenses, feed and replacing cull cows, collide. Now is the time to be thinking of your fall and winter nutrition plan to prevent decreases in body condition through the winter and calving. Start with knowing what you will need from a feed resource perspective. When do you need to start providing supplemental feed to cows that were previously grazing and for how long will you need to provide supplemental feed?

An additional unplanned month of hay can add up in a hurry, and finding good-quality hay last- minute within your budget can be a challenge. Next, figure out what you have to work with for feed resources. Whether hay, grain, byproducts or supplements, get your feedstuffs sampled for nutrient content so you know where the gaps are in your nutrition program. Forage analysis may seem like an expense, but it can pay dividends when it comes to formulating a balanced diet with correct nutrients, ensuring you aren’t over or underfeeding your cows.

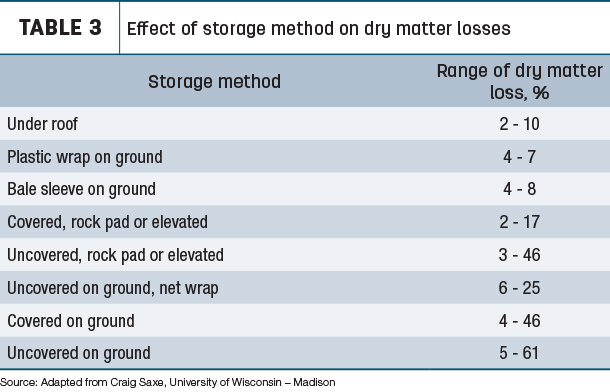

There are many non-nutritional factors to consider when trying to develop a fall and winter nutrition program. Some things are not nutritionally related but are hidden costs that can add unwanted expense to your nutrition budget. Improper, or lack of, feed storage and feeding methods can contribute to unintended additional feed expenses. Table 3 highlights dry matter losses associated with common storage methods, which decrease the feedable amount of hay.

In many cases, this is hay you’ve already paid for that goes to waste. For example, the tons of hay required to winter your cows could easily double if your storage program is inadequate.

These are only a few things to think about that can be controlled through nutrition and management to improve profitability. Utilizing professionals such as veterinarians and nutritionists to optimize critical jobs on an operation can save operators time and money, ultimately improving profitability.

This year has been fraught with externalities that have put huge pressures on people both emotionally and financially. It is extremely easy to get overwhelmed and highly tempting to throw up your hands in frustration and hope the government bails you out. Giving into that temptation will most definitely cost you hard-won progress within your operation.

The key to surviving events like these is to take stock of your resources, figure out what you have control over and use those findings to obtain the best bang for your buck. Don’t let those things out of your control cause you to forget that your main focus has to be profitability.