We’ve all heard the proverb “You can’t teach an old dog new tricks,” implying that once we become accustomed to doing something one way we are hesitant to change. However, when evaluating corn silage processing score (CSPS) or kernel processing score (KPS), this may not apply.

CSPS was developed in 2005 to evaluate the degree of processing of corn kernels in corn silage, and measures the amount of starch passing through a 4.75-millimeter (mm) sieve. For many years, the CSPS goal has been set at 70, with 50 to 70 being considered adequate and less than 50 considered poor. In the nearly 20 years since this analysis was introduced and these goals were established, kernel processing has been widely adopted as research has demonstrated a clear benefit.

These benefits include improved starch digestibility, milk production and feed efficiency. Multiple studies have reported processing greater than 5 mm yields significantly lower starch digestibility than that less than 5 mm. Additionally, inadequate kernel processing did not yield milk production or efficiency increases. This displays the importance of not only processing but proper processing and what a large economic impact it can have. One unit of fecal starch is estimated to equate to 0.72 pound of milk, and around 3 cents per head per day of undigested corn grain equivalents.

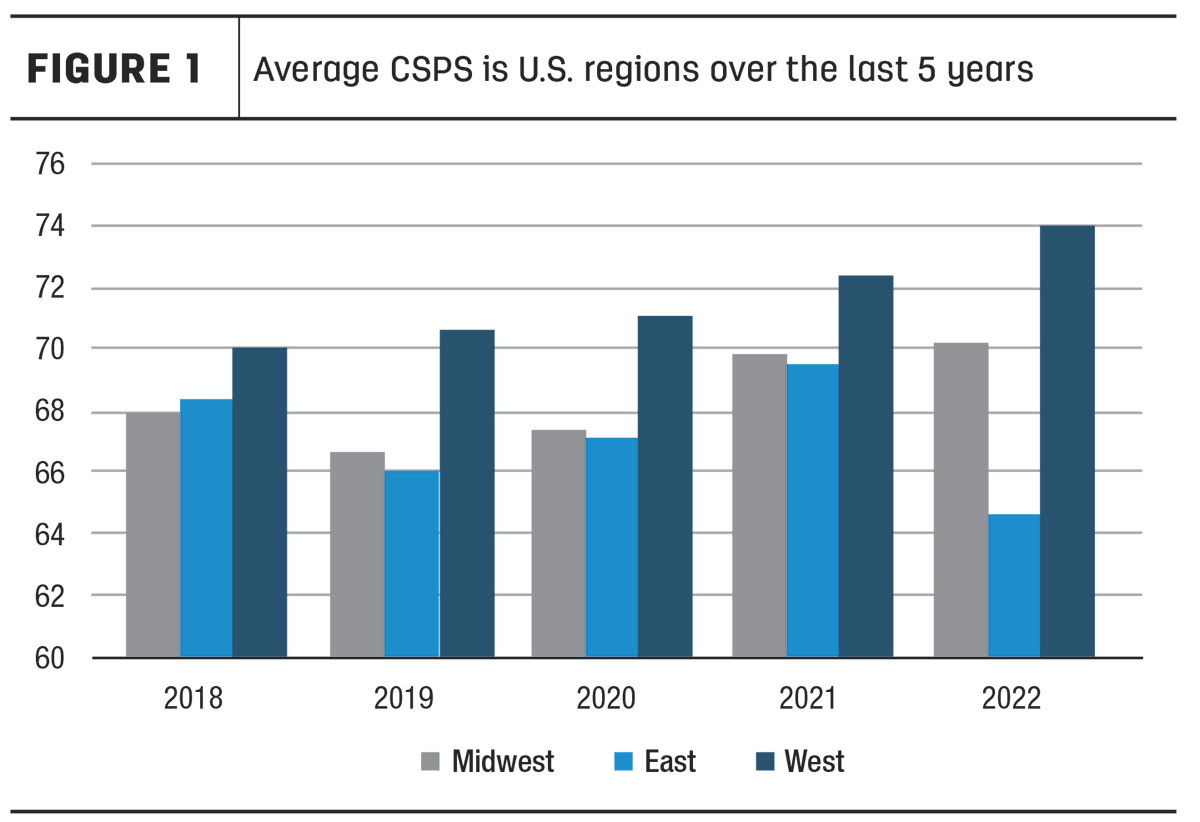

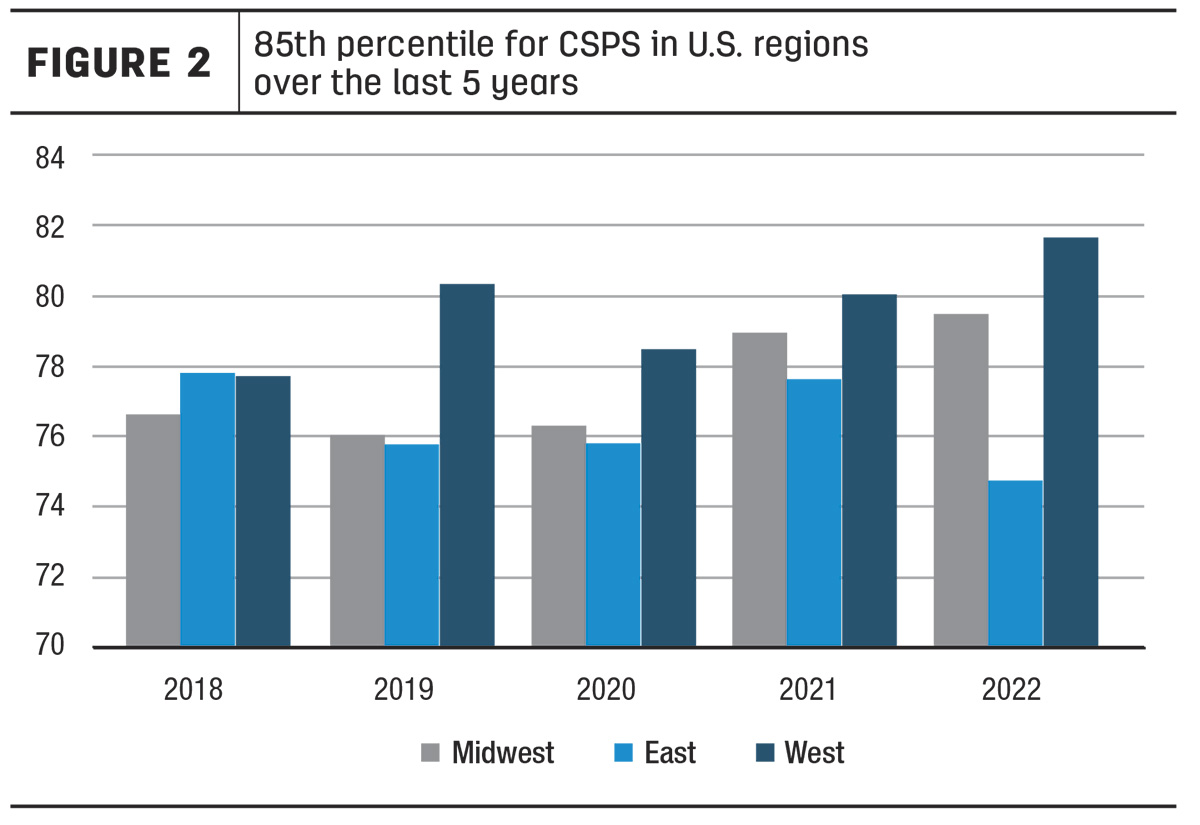

When comparing the industry goal to what is observed in samples tested for KPS at our company, almost 50% of samples tested are hitting the aforementioned KPS goal, and the top 85% of samples are nearing 80 KPS. While the bottom end does still suggest there is some below-ideal processing occurring, by and large, corn silage is processed well. We also see a year-over-year improvement of KPS – showing that improvement can be realized beyond initial goals. For some reason, this improvement has come more quickly in some regions than in others. For example, the year-over-year improvement in the western U.S. over the past five years has been impressive to say the least (Figures 1 and 2).

So while we are meeting or surpassing our goal of a 70 CSPS score in many situations, there still may be “new tricks” to learn. Thinking further about CSPS research, one could extrapolate that the portion of starch above the 4.75 mm screen will have greatly reduced digestibility than the portion below. This means that we should push to increase our CSPS to higher levels. Using our 85th percentile as a reference point, maybe the goal should be closer to a KPS of 80.

Room for improvement

We’ve quickly and efficiently adopted tools such as kernel processing to improve starch digestibility in corn silage. But when it comes to sorghum, which hasn’t been utilized to the same extent as corn silage, we may still be on the learning curve. A berry processing score (BPS) was proposed in 2015 to help quantify the amount and impact of processing berries in sorghum. In 2020, an amended BPS was suggested, using starch passing through a 2.36 mm screen. Although equipment has been manufactured specifically for berry processing, very little sorghum silage is harvested using this equipment.

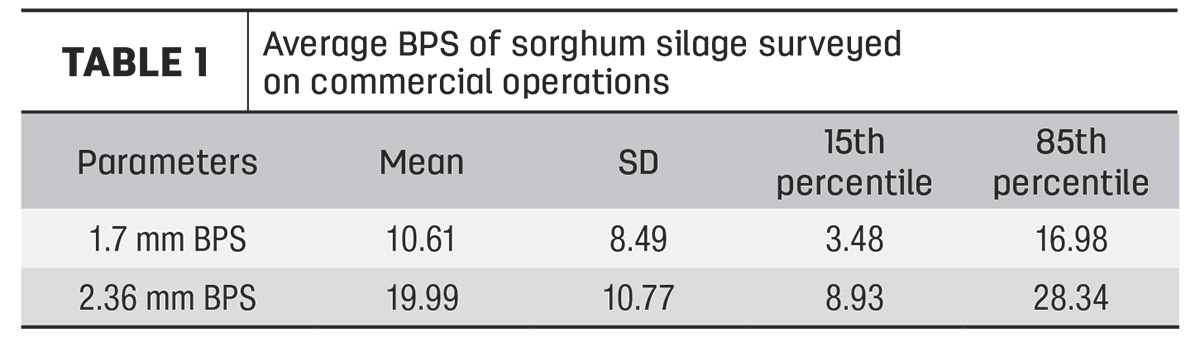

In 2022, our company completed a survey study to understand the degree of processing that was occurring in commercial operations (Table 1).

This study found that very minimal processing is currently occurring in sorghum silages, with an average 2.36 mm BPS of 20, a maximum of 57 and minimum of 5. It is known that unprocessed sorghum berries are difficult to digest and are associated with very little starch digestibility. Unlike corn silage, sorghum silage is often harvested over a large range of maturities, which is also associated with a large range of starch content. The survey study also reflected these ranges and found that silages with less starch content and lower dry matter (DM) were associated with higher BPS scores. This is not surprising as smaller berries are softer and more likely to either be susceptible to some sort of residual processing or may be small enough to pass through the 2.36 mm screen as is.

Although processing of sorghum berries isn’t occurring to the same degree as in corn, the benefits of processing are likely similar. One research study found a positive linear relationship between rumen starch digestibility and increasing BPS using a 1.7 mm screen. They found that starch digestibility was around 60% or less for samples with a BPS of 20, but starch digestibility was over 70% for a BPS of 50. Another study found that estimated ruminal starch disappearance was only 15% for whole berries and increased to nearly 40% for berries cut into four pieces. Harvesting at the soft berry stage can help prevent overly hard-to-process berries, but using correct processing equipment should also be considered to help maximize the starch available from sorghum silage.

Dairy producers have shown time and time again that we are capable of adapting new technologies and pushing them to their maximum potential. Corn silage processing is no different; however, there is still room for further improvement to help optimize profits. When it comes to different forages, we may have to look outside of our normal methods of processing to ensure we are maximizing the potential of the forages. Although we often write off the starch in sorghum silages, research has shown that proper berry processing can be a key to unlocking more of this valuable nutrient. With the cost of commodities, we can’t afford to be leaving money on the table or in the manure pile.