to jump to the article. Summary: This March 2011 article detailed facilities, bedding and cow cooling on four New York operations. Skip Hardie of Hardie Farms, Ryan Akin of Hemdale Farms, Dan Westfall of Aurora Ridge Farm and Mary Young of Young Farm talked about how they put cow comfort first. [Click here or on the image above right to see the full list of the Top 25 articles of 2011. Click here to see the list from 2010.]

ARTICLE

On a cold winter afternoon in North Lansing, New York, most people dream of warm summer days. This is not the case for Skip Hardie at Hardie Farms. Hardie knows that high summer temperatures increase the heat stress of his herd. Even in the cold winter, he’s thinking about how he can effectively and efficiently cool his cows.

"Where do you invest your money?" Hardie asked rhetorically. "I know that when I invest in something that improves the comfort of my cows, they will pay me back. I want to invest in a cooling system for my cows. I’m just not sure what that is yet."

Hardie, like many dairy farmers, must consider everything — from bedding surface and stall size to ventilation and lighting — to provide the best possible environment for their cows.

Click here to read about Hardie's thoughts on manure management and methane digesters from a 2009 Dairy Power Summit.

Hardie already installed waterbeds for cows and fans, but with new products continuously being introduced, new technologies being developed, and innovative solutions being shared throughout the industry, he must decide which steps to take to get the most out of his cows.

And he's not alone in doing research on cow comfort issues.

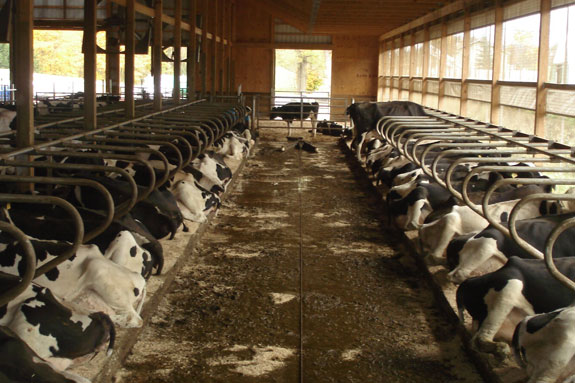

"We don’t have all the answers, but we aren’t afraid to try new things," said Ryan Akin of Hemdale Farms in Seneca Castle, New York. Hemdale Farms, a 900-head herd averaging 90 pounds of milk per cow, incorporated a number of techniques to increase cow comfort from the second they started moving dirt.

"The newest freestall barn, built in 2009, is situated on the property in an east/west orientation to maximize the natural wind movement, which increases ventilation," said Akin.

A combination of fans and mechanical curtain walls also play a critical role in ventilating the barn. The fans and curtain walls are engaged by a thermostat, which ensures the barn is kept at a constant temperature. In addition to the ventilation system, Hemdale Farms uses automatic controls to regulate the lighting system to ensure the cattle receive 16-18 hours of light per day.

Hemdale Farms was also one of the first dairies in New York to install waterbeds for cows 10 years ago. They have continued to install the waterbeds as they’ve grown their operations over the past decade. Now 100 percent of their herd is bedded on cow waterbeds.

"We’ve been sold on waterbeds for 10 years. They provide a clean, dry surface for the cows to lie on, and minimal bedding is required. They are an important part of our cow comfort plan," Akin said.

Recently, Hemdale Farms installed robotic milking machines to, "let cows be cows," Akin said.

"By milking with robots, our cows can do whatever they want, whenever they want. They eat when they want. They sleep when they want. They drink when they want," said Akin.

When a cow wants, she enters the robotic milking station, the machine scans the cow’s identification number to see if she needs to be milked.

If the cow is not ready to be milked, a gate will open on the opposite end of the station to signal the cow to leave the area. If she is ready to be milked, the milking cups are automatically placed over the teats and the milking begins. The process takes approximately 8 minutes, and the cow is fed food pellets while she’s waiting.

Click here to learn more about the robots at Hemdale Farms.

Hemdale Farms isn’t the only New York dairy utilizing innovative solutions to provide optimal cow comfort. Aurora Ridge Farm, a 1,700-head herd in Aurora owned by Bill Cook, already uses waterbeds for cows to bed their herd and designed the barns to have higher walls for more airflow.

"We pay attention to all the details because a lot of things come together to provide maximum cow comfort," said Dan Westfall, one of the two dairy managers on Aurora Ridge Farm. "We also look closely at where improvements can be made."

A few improvements that will be made on Aurora Ridge Farm this year include a switch to fluorescent lighting and the installation of rubber flooring in front of the feed lanes for improved cow comfort when eating.

Aurora Ridge Farm has already installed swinging cow brushes in the freestall barn.

"The brushes clean the cow, remove old hair, and studies have shown they increase blood flow. We also think the brushes provide a bit of fun for the cows. See, look at how happy she is,” Westfall said as he pointed out one cow rubbing against and playing with the swinging brush.

All investments on a dairy are scrutinized. Mary Young of Young Farm in Cuyler, New York, has already invested in high wall structures and fans for ventilation. Dairy professionals, like Young, will go to great lengths to provide optimal cow comfort, from installing waterbeds and climate control systems to putting in massaging brushes and ceramic tiles beneath the feed.

“Our girls like to eat off a plate, too,” Marty Young of Young Farm in Cuyler, New York, said about the ceramic tiles that provide a more hygienic place for cows to eat for their 450 head herd. PD

What steps do you take on your operation to improve cow comfort? Leave a comment below!

Amy Throndsen

Marketing and Business Development Director

Advanced Comfort Technology, Inc.

amy@waterbedsforcows.com

Follow Amy on Twitter at @amyserves