J. Craig Williams, a dairy educator with Penn State Extension, presented a webinar for the group in December, outlining the approved methods he has worked with to dispose of livestock.

Williams has worked with composting experts across the country on this subject and is always comparing information with them.

“Just be aware that not every method is approved in every state across the country, so you do need to be aware of what’s [allowed] in your state,” he said.

In Pennsylvania, there are four options for the disposal of livestock. They include burial, incineration, rendering and composting.

Burial

By law in Pennsylvania, livestock burial must be outside of the 100-year flood plain. It should be more than 200 feet away from any wet spots, ponds, streams or water.

Carcasses must be covered by a minimum of two feet of soil within 48 hours.

There are parts of the state where bedrock is less than two feet down and others with a high seasonal water table, which prevents burial in these locations.

Incineration

This is not open air incineration but enclosed units. Most modern units have a secondary burner on the flue gas.

Williams said some people indicate there is less management with incineration compared to monitoring a compost pile.

The downsides are incinerators require fuel oil to run and need to be cleaned out regularly to have the space to refill.

Rendering

“Rendering is permitted and encouraged,” Williams said.

However, with fewer companies offering this service, “rendering has vastly gone away for most of our producers in Pennsylvania.”

Composting

“Lately most of our people have been doing on-farm composting or bin composting,” he said.

Similar to the burial method, the carcass needs to be covered within 48 hours. A well-drained, high-and-dry site, 200 feet from water, sinkholes or streams is preferred.

Williams starts with a 2-foot-deep bed of woodchips.

“There’s a huge discrepancy on what a lot of people will call woodchips,” he said.

He uses wood chopped to less than 2 inches in length. The chips don’t have to be uniform, and there may be a few pieces that are 4 to 6 inches long, as well as some fines.

“We don’t like chunks, and we don’t really like what some people might call double-ground black mulch,” Williams said. That is something that has been treated. He prefers fresh woodchips.

On top of the 2-foot base, he might put down some old organic matter from other compost piles before laying the carcass on the bed.

This composting method works for large or small animals, he said, adding one option is multiple layers with large animals on the bottom and smaller animals on top, as long as there is two feet of carbon material in between the layers.

The direction the animal is placed on the pile can depend on the size of the animal and the pile, but it will help with management later if you can start to form a windrow.

Williams uses pre-heated material to cover the animal. This is organic matter from an existing compost pile, pre-stored woodchips, corn silage mixed with used dry bedding, or feedbunk cleanings. Each of these items has already begun the composting process and therefore is preheated to 100ºF to 120ºF.

The point is to get some activity already happening on the pile, especially in the winter when the other materials will be cold.

“Preheated cover makes the pile take off and work a lot quicker,” Williams said.

It is important not to cheat on the cover. Problems he has seen usually come from the cover being too thin from the start.

The pre-heated materials can be mixed with sawdust, chopped straw, chopped hay, cornstalks, spoiled silage or shredded newspaper if first used for bedding. Leaves do not work well, he said.

Williams suggested stockpiling materials so they are available when needed. Woodchips can be stored for several years, so take advantage when tree trimming trucks are in the area. When cleaning out bedded pack pens, feedbunks or spoiled silage, store about six months’ worth for pre-heated cover material.

Stockpiling is especially important for intensive grazing operations, as they have fewer carbon sources available from bedding and feed piles.

The materials for the pile should be around 50% moisture. Williams said, “If it’s too dry, we’re not going to get a lot of activity. If it’s too wet, we’re going to get some leachate, and we’re going to get some foul odors, but we can always add more carbon to a pile and dry it out.”

If a pile is too wet, it will hinder air flow throughout. “A properly aerated pile that is not too wet will have heat pulling off the top,” Williams explained. “That vacuum will bring the air in from the sides.”

Windrows work better than round piles for this reason. A narrow windrow can achieve air flow through the center of a pile better than a wide, round pile.

Plus, windrows are a better visual gauge for a timeline. He suggested building windrows six months at a time. If the first windrow is started in January, the next one would start in July and use some of the January compost as pre-heated cover in the July windrow. By comparing windrow lengths, you can also monitor the mortality situation on the farm. It also allows for bones not completely broken down to have a chance to compost some more in the next windrow.

When you’re getting ready to put your next carcass down, dig out a divot on the end of the pile and place the new carcass in line to form a windrow.

An active pile with enough carbon, heat, moisture and microbes will work all year round, even in colder climates.

Turning the compost is an option, but it isn’t necessary, he said. They can be turned with a compost turner or front end loader.

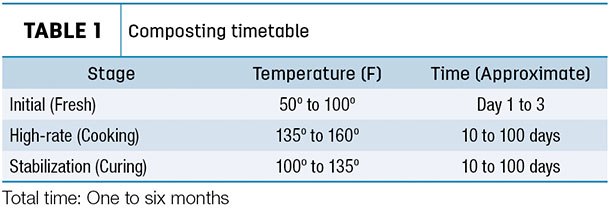

“Normally, mortality composting timeframe is about six months,” Williams said, referring to Table 1.

“We want you to reach 130 to 135 degrees for three days, sometime in that composting time. It will always reheat and speed up if you turn it, but you do not have to always turn mortality compost,” he added.

When opening a pile, Williams said to watch for a white layer. This is microbes that were killed once the pile reached a certain temperature. It is an indication the pile heated well.

Another composting option is in-vessel or drum composting, but in Williams’ experience, these methods usually require secondary composting in a windrow or pile as well.

He also mentioned grinding the carcass and mixing it with carbon to be composted in a windrow or structure, as well as air bin system being tried with livestock.

The air bin system pumps oxygen into a compost bin to speed up the process. “It’s another technology that’s been coming along here,” he said, noting it is currently being used for swine.

Whichever way mortality composting is carried out, it needs to be done in accordance with state regulations. Specifically, Williams said, hedgerow or fenceline dumping is not permitted in most areas. An approved process is needed to carry out carcass disposal on the farm. ![]()

-

Karen Lee

- Editor

- Progressive Dairy

- Email Karen Lee

Mortality composting resources

Here are a few online composting resources shared by J. Craig Williams:

- Cornell Waste Management Institute

- Maine Compost School

- Oklahoma State University Extension, search composting

- Penn State Extension website, search proper animal disposal or calf composting

.jpg?t=1687979285&width=640)