The application of raw manure to fields, while essential for soil fertility, often results in the release of pungent odours that impact not just the rural landscape but also the quality of life in nearby communities. However, a promising solution to mitigate these odours lies in the use of digestate from biogas operations.

The role of digestate from biogas operations

Digestate is a byproduct of anaerobic digestion, a biological process that breaks down organic materials in an oxygen-free environment, yielding biogas and a nutrient-rich residue (digestate). It is as nutrient-rich as the feedstocks that it receives, as the nitrogen, phosphorus and potassium are net-neutral. The digestate is much less odourous compared to raw manure due to the controlled decomposition process within the anaerobic digester. It contains valuable nutrients, making it a suitable soil conditioner and fertilizer, but without the overwhelming odour of raw manure.

The perception of odour is highly subjective, which can make it challenging to quantify and employ as a basis for classifying substances as having better or worse odours. Concerns about noxious odours emanating from residual fertilizing materials have long troubled agricultural communities, prompting the Ministry of the Environment, the Fight against Climate Change, Wildlife and Parks to categorize these substances into three distinct classes. This classification process involved a comprehensive public survey that engaged universities, the minister of agriculture and the general public. In this survey, participants were asked to rate various odours on a scale of 0 to 10, with 0 representing pure water and 10 representing the most unpleasant odour imaginable.

As a reference point, the average participant rated pig slurry at 8 and solid cattle manure at 4. Drawing from these ratings, the ministry established three primary categories:

Category O1: These substances are less odourous than solid dairy cattle manure.

Category O2: These substances exhibit a similar odour profile to solid dairy cattle manure.

Category O3: These substances possess an odour rating surpassing that of pig manure.

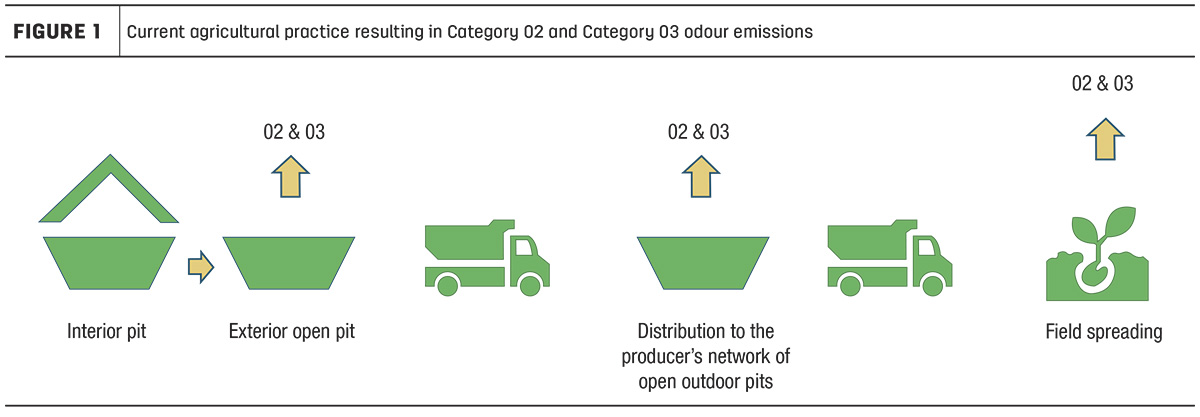

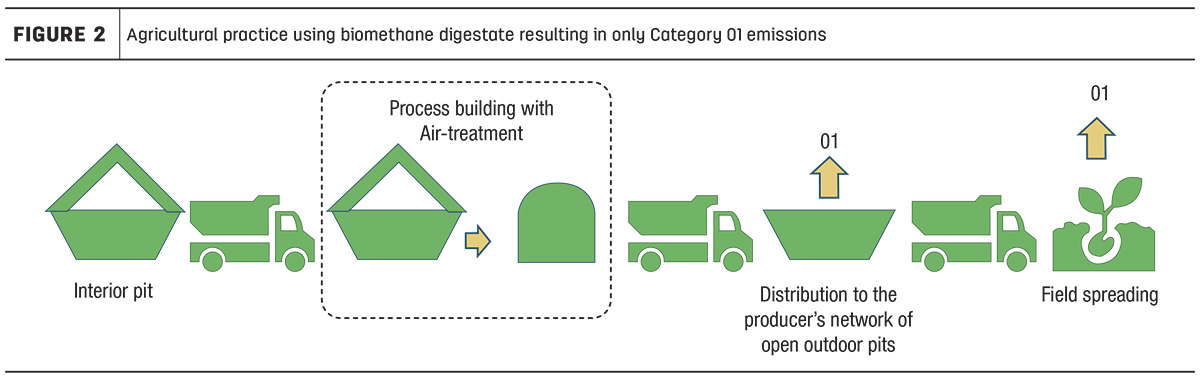

In the case of the average application of cattle manure, it falls into category O2. However, a comprehensive review of six odour studies conducted across various biogas production contexts, utilizing different types of animal manures, consistently yielded a compelling conclusion: The process of biogas production substantially reduces odour emissions. In certain instances, these reductions reached an astonishing 99% when compared to the untreated, raw counterparts. In each study, the results consistently indicated reduced odour emissions, often significantly lower than those of solid dairy cattle manure.

When comparing raw cattle manure to its digestated counterpart, we can confidently classify the latter as a category O1 odour. This lower classification brings assurance to farmers and farming communities that are exploring the utilization of digestate as a nutrient source to replace their raw manure counterparts, with the added benefit of achieving a net-neutral nutrient transfer.

When comparing raw cattle manure to its digestated counterpart, we can confidently classify the latter as a category O1 odour. This lower classification brings assurance to farmers and farming communities that are exploring the utilization of digestate as a nutrient source to replace their raw manure counterparts, with the added benefit of achieving a net-neutral nutrient transfer.

Understanding the odour issue

Manure odour primarily results from the decomposition of organic matter in the manure, leading to the release of volatile compounds like ammonia and sulphur compounds. When raw manure is applied to fields, these odourous compounds are exposed to the open environment, creating an unpleasant smell that can travel over considerable distances.

Odour reduction benefits

- Reduced ammonia emissions: One of the most potent and offensive odours associated with manure is ammonia. Digestate from biogas operations generally contains lower ammonia levels because the anaerobic digestion process reduces ammonia volatilization. This leads to less odour released into the surrounding environment when digestate is applied to fields.

- Controlled decomposition: Anaerobic digestion facilitates controlled decomposition, which further reduces the release of odourous compounds. This controlled process ensures that the odour emissions from digestate are significantly lower compared to raw manure.

- Mitigated transport of odours: Digestate's reduced odour profile means that the transport of odours to neighbouring communities is minimized. This is a significant benefit for those living in rural areas and close to agricultural fields.

- Improved quality of life: By choosing digestate over raw manure, agricultural communities can enjoy a better quality of life with reduced exposure to unpleasant odours. This can lead to increased well-being and satisfaction among residents.

Environmental benefits

Beyond the local community, using digestate for odour reduction offers several environmental advantages:

- Reduced air pollution: Lower ammonia emissions from digestate contribute to a reduction in air pollution, which can have a positive impact on air quality and human health.

- Less impact on ecosystems: Odourous compounds from raw manure can adversely affect local ecosystems. The use of digestate helps minimize these effects, benefiting wildlife and biodiversity.

- Sustainable agriculture: Integrating digestate into agricultural practices promotes sustainability by recycling valuable nutrients back into the soil. This enhances soil fertility and reduces the need for chemical fertilizers.

The use of digestate from biogas operations in place of raw manure offers agricultural communities and the environment a promising solution to the persistent problem of odourous emissions. By choosing digestate, agricultural practices become more environmentally friendly, with reduced odours, improved air quality and sustainable soil fertility enhancement.

As the agriculture industry continues to evolve toward more eco-friendly practices, the adoption of digestate as a viable alternative to raw manure represents a significant step toward a healthier and more harmonious coexistence between farming and neighbouring communities.