Retrofitting a dairy barn has been a popular choice to make upgrades more affordable than they would be when building new, yet “retrofitting” isn’t unique to the dairy industry. Many buildings today are serving different purposes than the ones for which they were originally built – maybe even serving a different industry.

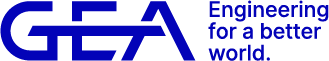

In dairy, as with most buildings which are converted for a new function or purpose, both physical and operational changes will be essential to support the new function of the build. Adding robotics to your daily operations will require similar changes to your dairy farm, and the resulting new routines and management strategies will require a whole new mindset as well. Coming from 20 years in the architecture and construction industry, I can tell you: Retrofitting a dairy barn will require both physical and operational changes, same as many buildings in other industries (Figure 1).

Physical changes

In the U.S., it is typical to place your new robot in a wall or opening of a room. This room should be adequately sized per the manufacturer’s minimum clearances and design parameters for proper installation, operation and maintenance. All of the pneumatic, plumbing, drainage and electrical supply lines should be provided within the room per the manufacturer’s specifications. Does the original building have a room that can accommodate this, or will that part be new?

Your new or repurposed robot room should have clean access or a boot wash outside of the room, helping to keep the room clean of fecal matter. Within the room, the floors should be sloped with adequate floor drains or trench drains along with a hose bib and a hand sink. The finishes inside the room should be easily washable and durable.

A positive air supply delivered from within the room will push air out to the barn while keeping surfaces dry. All of these hygiene variables are regulated at some level, and requirements will depend on your local inspector and local codes. Keeping your robot and room clean will help with smooth operations and less maintenance on your robot. Directly outside of the robot room should be a commitment or fetch pen area, depending on the cow flow of the barn. An existing, conventional barn will likely need something completely new to meet all of these needs.

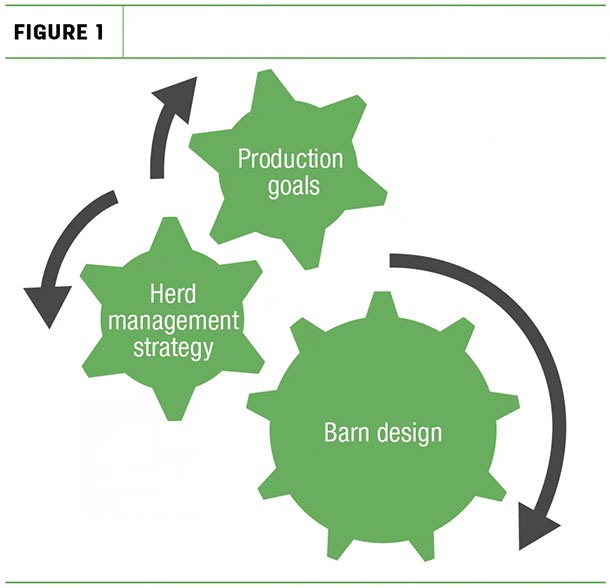

On most retrofit dairy barns, there will be an existing milkhouse for your milk collection (Table 1).

This space can be reused or modified to support robotic milking but, in some cases, this milk collection point is too far from the renovated dairy barn, and a new milkhouse and equipment room will need to be built. Keeping the milk transport lines a short distance from robots to the milkhouse will keep initial cost down due to less material needed and will make cleaning easier. The number of robotic milking units will also impact the required capacity of the existing milk tank.

Another option is to have an equipment room adjacent or near the robot room, which can be small to medium-sized depending on the number of robots in the plan. This room will contain support equipment such as vacuum pumps and water heaters. While the size of the room will depend on the equipment housed, the actual location should be as close to the robot as possible. Other items such as divert milk racks, detergents and cleaners can also reside here.

Operational changes

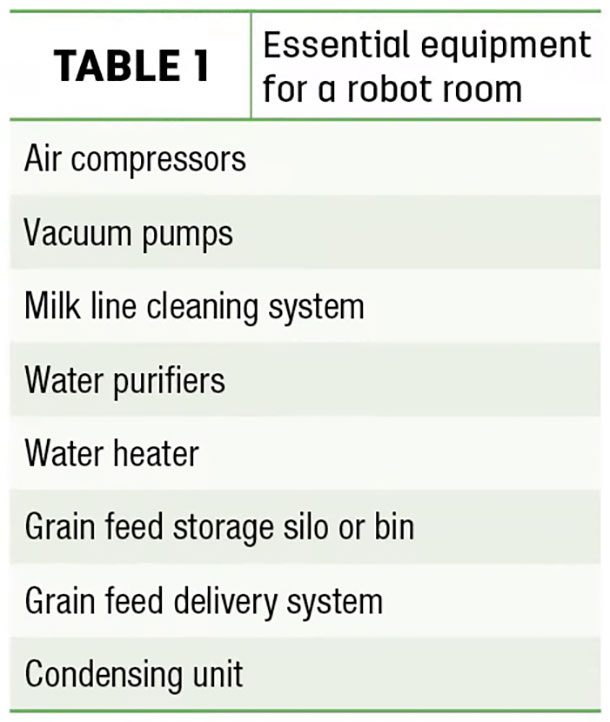

A major change to a building will require a major change in operational functions. These changes will affect the whole barn. Depending on the goals of the dairy, many operational items must be established during planning of the retrofit design. One major consideration will be the gating and flow within the barn to and from the robot. Free flow and guided flow are two of the options (Table 2).

Free flow is exactly what the name entails: The cows are allowed to walk around freely wherever and whenever they choose within the barn, without any gates. Guided flow allows the cows to go from one area of the barn to another in an organized procession with a series of gates. Both have their advantages and disadvantages, and this decision plays a major role in the retrofit planning.

Additional operations that will change, both in nature and location, include waterers, footbaths, hoof trimming, rations and bedding type. These factors are influenced by your goals, which will affect your management strategies, ultimately impacting the design of the retrofit.

Work outside of the dairy industry, from power plants to commercial restaurants, has taught me that modifying and repurposing a building requires physical preparation for the new equipment and functions, while understanding the needs or goals of the occupants, owner and operators for these future changes. These principles apply when adding robotics to your existing dairy barn, regardless of the number of robots being installed. When we can start to look at a retrofit as a whole new purpose for the building, with new goals and new management strategies, it’s easier to see exactly how we need to reconstruct your barn to meet your new needs.