What follows are summaries from The Cow Tech Report about cow technology news that has made headlines so far in 2021.

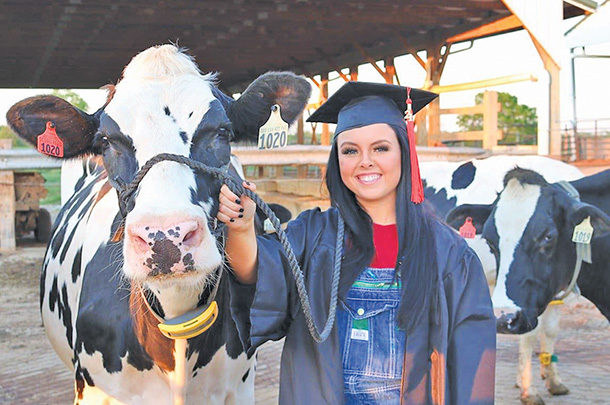

U.S. Holstein association aims to transform 50-cow university herd with technology

Holstein Association USA recently announced a collaboration to transform a 50-cow U.S. university herd into a top-tier genetics herd using the latest cow technologies. The effort aims to push the university herd, and overall breed advancement, forward. The herd at Western Kentucky University, which has been doing dairy cow research for more than half a century, is the selected herd for this new experiment, which is being dubbed “the SmartHolstein Lab.”

According to a release announcing the news, the lab has been established as an easy-to-access demonstration and development farm to explore new technologies designed to collect novel phenotypic traits, including wearable or indwelling sensors and milk-based biomarkers. Emphasis will be placed on practical use of data for on-farm decision-making. The herd will also be a nucleus herd for genetic selection strategies and collection of novel phenotypic information.

The long-term goal, according to the association, is to develop a 100% A2, polled herd of cows in the top 20% of the breed for TPI with additional emphasis on health, reproduction and fitness traits.

The lab says that “many” industry partners have already donated technologies.

New newsletter about robotic milking for large herds

If you’re interested in robotic milking for large herds, there’s a new newsletter that might intrigue you. Researchers at UC – Davis and the University of Minnesota are studying the opportunities and risks of implementing automated milking systems on large dairies. They are reviewing what has been published about the topic already and doing original interviews with dairy farmers as part of their research. This newsletter shares updates on their work.

Recent issues have featured an interview with the first California dairy to install a milking robot and the manager of the largest milking robot farm on the planet.

To subscribe to the newsletter or read the current issue, go to University of Claifornia - Dairy Tech News.

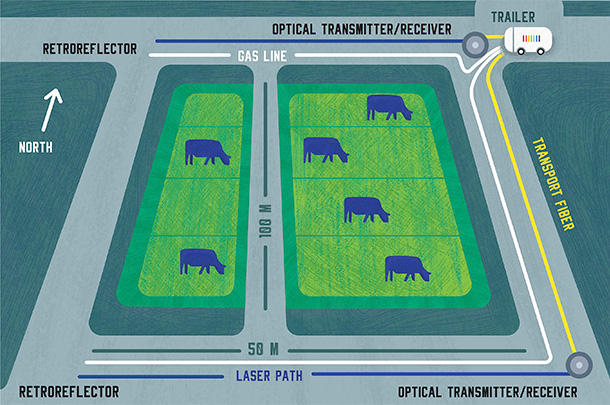

Laser light used to measure drylot’s greenhouse gas emissions

Photo by Hanacek/NIST

Photo by Hanacek/NISTDFA announces its 2021 accelerator class

Facial recognition software for cows, nanotechnologies to help treat mastitis and farm data aggregation software are the cow-tech-specific startup companies that are convening virtually for Dairy Farmers of America’s (DFA) 2021 CoLab Accelerator class.

“We’re really excited about this year’s class and the potential for their innovations,” says Doug Dresslaer, director of innovation at DFA. “It’s a very diverse group with some cutting-edge ag technologies that can help solve problems and benefit our farm family-owners as well as product-focused startups that are exploring new possibilities for dairy foods.”

The companies participating include:

- CattleEye – Aims to deliver a deep learning, cloud-based AI platform designed to interpret visual imagery of cattle from industry-standard web cameras. The platform autonomously identifies individual animals to extract insights including measuring gait, applying mobility scores to track lameness and other positive welfare indicators.

- DairyOffice – Designed as a central location for all datasets collected on a farm, this platform is built to integrate with herd management software and sensors, feed systems and ration formulation programs. The platform then manages the collection of data and provides various spreadsheets and other analytical tools updated with the collection of new data.

- VERI Nano – Created a patent-pending nanotechnology that is utilized as a bovine teat sealant, disinfectant, antimicrobial coating, skincare and wound care treatment. It is aimed to be more cost-efficient and effective than current mastitis treatments.

The DFA CoLab Accelerator is a 90-day immersive program focused on dairy product innovations and new technologies for dairy farms.

New barn monitoring sensor available

The milc group recently launched a new sensor-based system that alerts dairies if barn processes, like wash-up, fail. It is customizable to work on all dairy operations regardless of equipment provider. The new technology is called Watchdog.

The program uses temperature and pH sensors to detect system failures. It can send real-time, in-app notifications to producers to alert them of problems when they begin.

New milking pulsator a ‘quantum leap’ forward

A New York-based company that claims it has the “only humane way to milk an animal with a machine” has recently been awarded for its most recent innovation. LR Gehm LLC is the recipient of a 2021 American Society of Agriculture Biological Engineers AE50 Award for its Trident Pulsation system. Data from dairy farms using this product was provided as evidence of the product’s performance.

This new product is the culmination of several years of development and introduces several new, patented technologies. A few of the new features include a real-time integrated functional performance monitor, a feature to ensure proper liner attach followed by a brief stimulation period, a positive-pressure fresh air system to optimize liner performance that allows for full liner closure even with no vacuum in the liner and a unique air/vacuum action to reduce/prevent the pull of liquid up into the pulsator in the event of a liner failure.

Shot-delivering robot nearly a reality

Screen capture from Pharm Robotics YouTube channel.

Screen capture from Pharm Robotics YouTube channel.The dairy start-up that emerged during the pandemic last year now has a prototype to show the world. Pharm Robotics recently posted a video of a sample robot arm working inside of its concept cattle-handling chute. The company aims to create a robotic arm and handling chute to automate the delivery of pharmaceuticals, vaccines and reproductive shots to dairy cows.

The company is crowd-funding its development.

“We’re well on our way and pumped as a team to complete development on our robotic health center,” the company’s CFO Alika Chuck posted on LinkedIn.

Vertical fodder company announces second system in Colorado

Utah-based Grōv Technologies recently announced it signed agreements with Colorado-based Hunter Ridge Dairy to build 10 of the company’s vertical fodder towers as part of a new indoor feed center. The 10 units will produce 60,000 pounds of fresh, sprouted grain per day, year-round. As configured, the to-be-constructed feed center will sit on approximately one-third of an acre, yet it will produce the equivalent of 350 to 500 acres of field-grown fodder using less than 5% of the water.

Two cow tech companies partner, announce new dairy herd management technology

Waikato Milking Systems and Nedap recently announced a new partnership and two new products. Waikato recently introduced its new cow monitoring system, CowTraQ, and its new TracHQ automation platform, both of which will be powered by Nedap.

The two new products offer dairy farmers the following advantages: real-time and relevant alerts, to-do lists, reports and barn maps to help manage and control the herd. A single collar combines animal identification, heat detection, health monitoring, herd performance trends and cow locating to improve herd performance.

“Nedap’s widely proven and integrated platform drives herd management technology such as CowTraQ and TracHQ to automate everyday tasks and deliver complete and user-friendly insights to dairy farmers to help make informed decisions,” says Bertino Verstege, Nedap Livestock Management managing director.

Visit the companies’ websites (Waikato Milking Systems or Nedap) to learn more about these new cow monitoring systems and herd management technologies.

Herd management software company starts text-based customer service

The company expanding a cloud-based version of its herd management software now offers weekday text support. VAS recently announced the new feature on its LinkedIn page.

“Yes, you read that right, we now offer text support through our regular call line. However you want to reach us – call, email or text – the same great support team you’ve come to know is here to help.”

SmaXtec enters U.S. commercial market

The rumen bolus company that has been selling its boluses commercially in Europe and Oceania for years is coming to the U.S. SmaXtec recently announced it would sell and support its bolus technology in the U.S. with an office based in Madison, Wisconsin.

The company claims its rumen boluses can detect internal body changes inside of a cow within plus or minus 0.18ºF of accuracy. Most impressively, the company claims its boluses can detect diseases up to four days prior to external, clinical signs. That’s two days faster than most activity monitoring companies claim they can detect cow health deviations. The company claims its faster detection is “the new gold standard.”

SmaXtec currently operates commercially in Germany, the UK, the Netherlands as well as in Australia and New Zealand. However, the company’s technology has been in use on research dairies in the U.S. at Oregon State University, University of Kentucky and the William Miner Agricultural Research Institute.

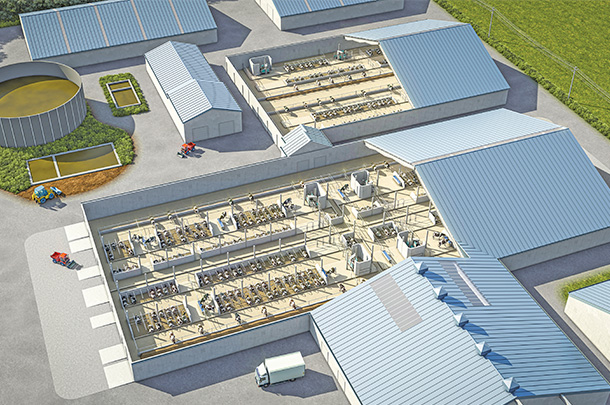

Largest robotic milking research facility in North America to open in Canada

Photo courtesy of GEA.

Photo courtesy of GEA.The University of British Columbia (UBC) Dairy Education and Research Centre recently announced that it will remodel its 20-year-old parlor into a fully robotic milking facility. The installation of six milking robots will make it the largest robotic milking research facility in North America.

“Becoming a research farm milking 100 percent of our herd with robots is significant, as it is representative of dairy farms adapting to robotics worldwide,” says Nelson Dinn, UBC business operations manager. “We want to position the UBC Dairy Centre as a technology hub at the forefront of dairy cattle research globally.”

The renovation project will have a flexible design incorporating a total of six GEA robots in two existing research barns, housing about 250 lactating cows, along with one training robot. GEA will install its R9500 box robots for the project.

“We’d like to take what we’ve learned with conventional milking and dive deeper using new data we can obtain from automated milking systems,” says Ronaldo Cerri, UBC director and associate professor in dairy cattle reproduction.

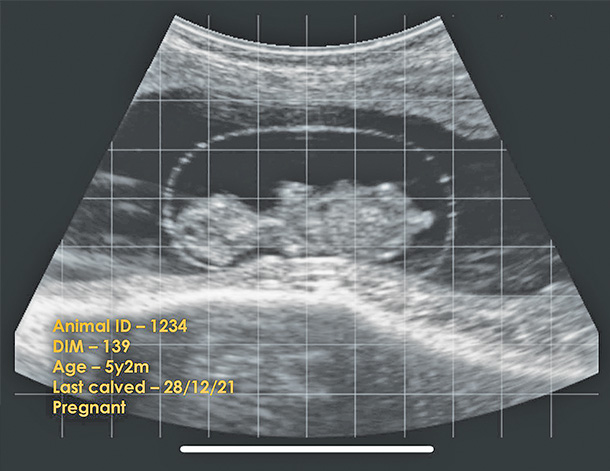

Ultrasound scanner will pair ultrasound images with herd data

Photo courtesy of IMV Technologies.

Photo courtesy of IMV Technologies.A company that offers a handheld ultrasound monitor for use to preg-check cows recently announced that its hardware will now be able to pair with herd management software. This will enable the device to display key performance data about a cow within the view of the ultrasound technician.

IMV Technologies launched the integration this past summer for its Easi-Scan:Go ultrasound scanner for farmers using HERDEmobil, a European-based herd management software.

“Data networking has been on the agenda of our software for years. As an independent herd management program, we depend on effective connectivity. Our users from the field of veterinary medicine and fertility management are thus moving even closer to the livestock farm and will further deepen their caring activities,” said Dirk Leuschke, CEO of dsp-Agrosoft GmbH, the company that owns HERDEmobil.

The company’s software catalogs herd information for more than 1 million cows on 3,000 farms worldwide.

The two companies claim what they’ve done is a first-of-its-kind integration of herd management data and ultrasound imagery.

Research fellowships awarded to create web-based interface for dairy data, address cybersecurity on dairy farms

The Dairy Innovation Hub at the University of Wisconsin – Platteville recently announced two research fellowships focused on cow-centric technology.

The first project will focus on understanding how farmers currently use their data to make decisions and analyze how a decision support framework could influence daily operations to increase herd health and revenue. Researchers will attempt to create a light and efficient web-based platform for a dairy’s data based on discussion with farmers and their consultants. The goal of the new platform’s development will focus on ease of use, getting data to a place where it is more easily stored, analyzed and actionable in order to make farm management decisions.

Another project at the university aims to evaluate the variety of cybersecurity threats and attacks that could target herd-level, day-to-day dairy farm operations. Researchers will outline the security posture of the university’s dairy farm at UW – Platteville by performing a comprehensive risk assessment and recommend measures to mitigate identified risks. These findings will then be generalized to investigate common cybersecurity issues facing the dairy sector.

Subscribe to The Cow Tech Report to receive news about technologies like these and more on a regular basis. Visit The Cow Tech Report to sign up for a free biweekly newsletter or pay and subscribe for exclusive access to weekly information.