The abundance and quality of forages for dairy cattle are impacted by weather and growing conditions. Despite our best management efforts, there is always a looming risk that adverse events will lead to a shortage of home-grown forages.

When forage shortages do occur, there are a number of forage alternatives that exist to help reduce feed costs, minimize production losses and stabilize farm profit.

Affordable alternatives to alfalfa haylage and corn silage are essential to filling this forage gap. Crop residues, including corn stover, may provide part of the solution for dairy producers during forage shortages. However, because corn stover has inherently low nutritional value for dairy cows, it typically is left in the field. This occurs despite an agronomic excess in meeting needs for soil health and subsequent crop yields.

Consequently, corn stover may have greater potential as a feed resource for lactating dairy cows if harvest, treatment and storage or handling methods were available that unlocked the energy and other nutrients corn stover contains.

In addition to the inherent low digestibility of corn stover, it may have limited value due to the relatively low bulk density and associated handling and transportation costs.

Improving the feeding value of corn stover is a challenge because, as a byproduct of corn grain production, the corn plant has a high lignin content. As the corn plant matures, the proportion of lignin increases to keep the plant upright in the field prior to harvest, and the more digestible cellulose and hemicellulose fractions decrease.

When fed to cattle, the high lignin content of corn stover acts as a barrier around cellulose and hemicellulose, preventing bacterial attachment, penetration of the cellulose enzyme to the plant and subsequent digestion by rumen bacteria.

Mechanical and chemical treatment processing of corn stover works to disrupt the lignin barrier and increase the accessibility of cellulose and hemicellulose for digestion by rumen bacteria. These processes act to improve the nutrient digestibility of corn stover and may provide options for using corn stover in diets for lactating dairy cows.

Recent research by our group at Purdue has revealed that corn stover can be chopped, hydrated to 50 percent moisture and treated with 6.6 percent calcium hydroxide and, when combined with distillers grains, can serve as a partial replacement for either alfalfa haylage or corn silage in diets fed to lactating Holstein cows without negatively impacting milk production.

Furthermore, feeding calcium hydroxide-treated corn stover resulted in greater efficiency of conversion of feed to milk, and consequently income over feed costs were greater when treated corn stover was included in the diet.

A second challenge in considering use of corn stover as an alternative feed for dairy cows is the low bulk density and related transportation inefficiencies for redistribution from site of production.

Densification through pelleting may be a solution. Furthermore, fortification of corn stover through combining with other commodity feeds during the pelleting process creates a feed that is distributed more effectively and better meets the nutritional needs of lactating dairy cows.

In order to assess suitability of corn stover as an alternative forage for lactating cows, we ground corn stover through a tub grinder, followed by hydration to 50 percent moisture, application of calcium hydroxide (hydrated lime) slurry to 6.6 percent of dry matter, and stored it in an AgBag silo.

We chose calcium hydroxide due to its less caustic nature than other chemical treatments, including sodium hydroxide. Processed and chemically treated corn stover was partially dried and blended with other byproduct feeds and further processed into a densified, nutrient-fortified treated corn stover pellet.

The resulting enriched corn stover pellets had a nutrient profile that resembled corn gluten feed, a non-forage fiber source and commonly considered forage alternative during feed shortages.

Eight ruminally cannulated mid-lactation Holstein cows were used in the experiment to evaluate the effects of feeding fortified corn stover pellets on milk production and composition.

Fortified corn stover pellets replaced a portion of the alfalfa haylage and corn silage in diets fed to lactating dairy cows. The experimental design was organized so that all eight cows went through each of the four diets over the course of 84 days. The diets used in the study were:

- A control diet which contained corn silage and alfalfa haylage as the primary forages

- A partial replacement of corn silage and alfalfa haylage with fortified corn stover pellets to 21 percent of the ration dry matter

- A further replacement of corn silage and alfalfa haylage with fortified corn stover pellets to 40 percent of the ration dry matter

- A ration where 40 percent of the diet consisted of the same ingredients as the fortified corn stover pellets but added as fresh TMR ingredients

Feed intake, milk production and milk composition were measured throughout the 84-day study, and bodyweight and body condition score change were evaluated.

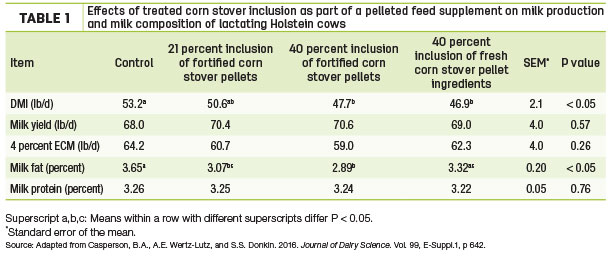

The greater inclusion of treated corn stover either in pelleted or fresh form did not change milk production (Table 1). Although feeding fortified corn stover pellets slightly reduced milkfat percentage, there was no effect on 4 percent energy-corrected milk. Moreover, the same level of production was realized with less feed.

Consequently, feeding fortified corn stover pellets in place of corn silage and alfalfa haylage tended to improve feed efficiency. Thus, the data confirm that fortified corn stover pellets can effectively fill the forage gap during a home-grown forage shortage.

Consequently, feeding fortified corn stover pellets in place of corn silage and alfalfa haylage tended to improve feed efficiency. Thus, the data confirm that fortified corn stover pellets can effectively fill the forage gap during a home-grown forage shortage.

Furthermore, if pricing is equal on a dry matter basis to the forages that are replaced, then there are gains realized for income over feed costs.

Being prepared for inevitable forage shortages with alternative feeds and research-based knowledge for incorporating them into current feeding programs can help avoid major production setbacks and income losses. Pre-storage processing and treatment appears to be the key to unlocking the potential of corn stover as an alternative forage source for lactating dairy cows.

Added benefits to the improved feeding value of corn stover with calcium hydroxide treatment is high calcium content of the feed and decreased need for added calcium in the TMR from other sources. However, the higher calcium content of treated stover may also limit inclusion in diets for dry cows and growing heifers.

Your local crop consultant can help offer advice in corn stover harvesting, handling and treatment strategies. Your nutritionist may see a role for calcium hydroxide-treated corn stover and fortified corn stover pellets to help stretch your forage resources the next time home-grown forage supplies are limited. ![]()

This research was presented at the 2016 meeting of the American Dairy Science Association in Salt Lake City, Utah, July 19-23, 2016 and supported by ADM Animal Nutrition Inc.

Shawn S. Donkin. Ph.D., is a professor of animal sciences at Purdue University. Email Shawn S. Donkin.

-

Brittany A. Casperson

- Ph.D. Candidate Department of Animal Sciences

- Purdue University

- Email Brittany A. Casperson