This year’s harvest season has now come to an end, which means it’s time to start the groundwork for next year’s crop season. Have you started winterizing your equipment? Now is a great time to start planning for the next year. Start performing any repairs that may be needed on any of your machinery before you store it. I always like to use my senses whenever I am operating equipment. I use visual indicators to let me know if anything is wrong or needs work. I also try to keep a note pad in case I need to make a note which helps keep track of repairs or maintenance procedures that should be performed on equipment.

When inspecting the equipment, walk around it and look underneath it. Look for tell-tale signs that could lead to mechanical failure, such as leaks. Whether it is antifreeze or oil, there will be tell-tale signs of splatter because dust will collect around those parts.

Inspecting your equipment now will help head off problems that you could have the next time you use your equipment – whether it is tomorrow, next week, or next year.

As agricultural producers and equipment operators, we are busy people and sometimes we do forget to perform basic maintenance on our equipment. Now is the time to concentrate more on the issues we may have encountered earlier this year because it is still fresh on our minds.

I think it is key to repair and perform maintenance procedures on your equipment the same year in which you operated the equipment. If you neglect your equipment over the course of winter, you could expose that equipment to risks associated with wintry weather, such as freezing or any type of wintry precipitation.

Two basic maintenance tips are to always keep your equipment clean and lubricated.

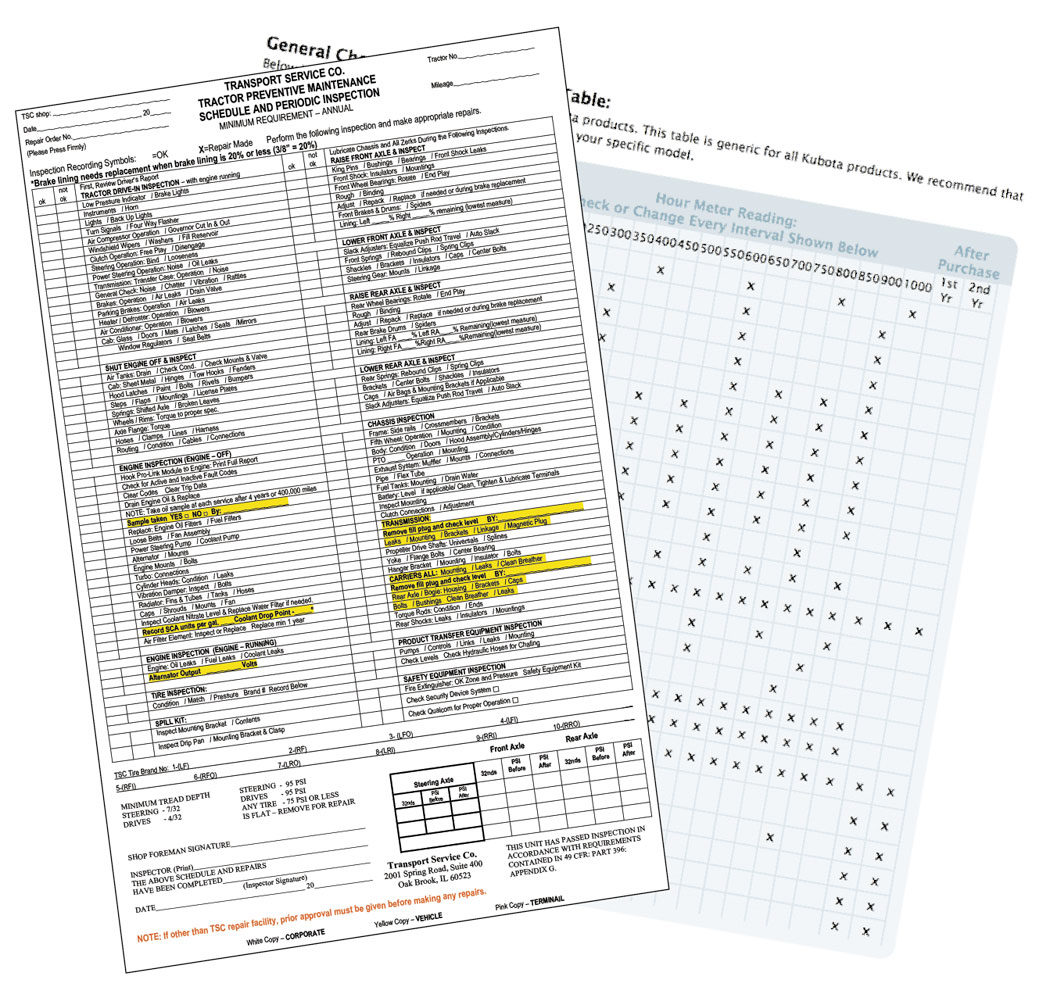

Dealer checklists or mechanical checklists can be very informative and thorough. Certain engines and equipment have maintenance checklists based on the age or the number of hours that equipment has operated. These checklists are excellent to keep and follow.

The following are a few areas I believe should be given additional attention.

Coolants

Coolants sometimes are the cause of problems that at first may go unnoticed. For example, if a person has a problem with the coolant system of an engine and puts water into the system, he or she may forget about it. When winter comes along and the engine coolant system still has water in it, that water will freeze and cause some damage.

If you use a 50:50 solution or use only the correct coolant and bleed it, then you are probably fine. However, if water was added, make sure to bleed out the system and replace with the proper coolant.

Belts

Belts are always a big issue. The ones manufacturers install in the equipment are pretty much designed and designated for that area. If you replace the original belt with one from a generic parts store, it will probably wear out or stretch out faster.

Try to buy parts from the manufacturer, as they made that piece of equipment. They know more about that piece of equipment than anyone, including its failures and weak points.

Filters/oils

You have to be careful with filters. Some filters are specially designed for the engine or hydraulic system. You should try to avoid letting the engine sit all winter with dirty oil. As the oil breaks down, it can produce acids that can erode your engine parts. Service the equipment by using the correct filters and the proper oils.

In the past I have seen hydraulic filters that froze during the winter, stopping all oil flow. No oil meant no hydraulics, which became a problem.

Batteries

Usually when cold weather hits, you start having battery problems. See how well your battery is holding up before you store that piece of equipment. If it is needed, replace the battery either then or make a note to replace it before you use the equipment again.

Other parts you may want to look at are the valve adjustments and pulleys.

Cosmetics and comfort

The cosmetics of the equipment can also be important. Save yourself the time you might not have next year. This includes tasks such as cleaning, waxing, painting, or replacing tires. You might also consider repairing or replacing your seat. Replace those old floor mats that you stumble over.

Although many operators don’t give much thought to it, convenience and comfort should always be considered. If you are going to pay someone to operate your equipment, or if you are operating it yourself, wouldn’t you want some comfort?

Not everybody runs new equipment. You don’t have to go buy a new piece of equipment, just make sure to keep it up.

Lastly, I think it is important to always establish good rapport with your equipment dealer. They can do a lot for you if you communicate effectively with them. As the owner or potential buyer of a certain piece of equipment, you should always ask questions.

If your equipment is under warranty, now is the time to have repairs done. If the equipment has a leak, get it serviced.

If I know one thing that happens, it is that things can get away from us. Stay ahead of the game this winter. Don’t wait until you have a problem to fix; remember you are trying to head off those potential problems.

Mechanic’s Tip:

You want to be really careful with antifreeze because some antifreeze checkers will not check your antifreeze. You may need a refractometer. PD

-

Jim Schlund

- Retired Diesel

- Mechanics Professor

- College of Southern Idaho