The complexity of dairy nutrition is increasing every day. A higher percentage of diets are likely balanced for amino acids, taking into account digestibility measures such as digestible NDF, and fine-tuning specific carbohydrate fractions such as starch and sugar. With price volatility in today’s market, feeding the right diet at the right time has never been more important.

The goal of this article is not to tell you how to take advantage of new nutrient systems; rather, it is to take a step back and talk about the importance of good nutrient measurement systems. How can you build a complex diet with precise nutrient concentrations if you do not know with certainty the nutrient content of the ingredients (forages, grains, byproducts) that you are working with? A solid foundation must be completed before the rest of the house can be built.

We are all aware of the three diets that exist on the farm: the paper diet, the diet you put into the mixer and the diet that cows eat. There are many reasons why these diets may differ. One of the key reasons is the difference between the nutrient content of ingredients in the ration formulation system and the actual nutrient content of the ingredients on the farm. When this occurs, there is no way to closely match the paper diet with the diet the cows ultimately receive, even with tight feeding management practices. Our foundation of information is weak and even a well-constructed house will develop cracks and ultimately fail.

This is where ingredient sampling and variation in nutrient measurement come into play. When we think of sampling, our mind typically jumps to laboratory analysis. This is a key component of understanding the nutrient content of our ingredients that I will discuss shortly. Before moving to the lab, however, I want to stay on the farm and look at one of the key nutrient measures that must be managed at the farm level – moisture. Accurate moisture measurement and timely diet adjustment is the cornerstone of our foundation.

Let’s take a look at the impact moisture can have on a diet. For example, the forages in the diet currently being fed are 42 pounds of corn silage, 10 pounds of haylage and 6 pounds of hay. A heavy rain occurs one evening and you notice a day or two later that the cows seem to have dropped some on milk. Could this have come from the diet? If you didn’t take into account the moisture change of your wet forages, it likely could have come from the diet.

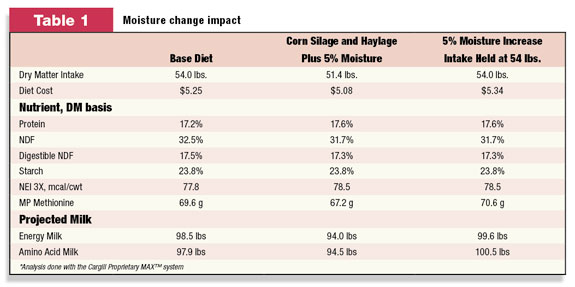

Table 1 shows the impact that a 5 percent increase in moisture of the wet forages can have on diet nutrients and potential milk production. The nutrient differences may look minor but their impact is magnified by the potential loss of 1.6 pounds of dry matter intake. If cows cannot gain access to extra TMR to cover this intake loss, they can potentially lose about 4 pounds of milk. At $13 per hundredweight that would mean a loss of $0.52 of milk income per cow. The lower dry matter intake does mean that the cost of the diet goes down by $0.17, leaving you with a net loss of $0.35 per cow per day.

In certain situations, cows will have access to some additional dry matter if we feed for a 3 to 5 percent overage at the bunk. In this scenario, you need to be lead-feeding a full 5 percent and have the cows eat to an empty bunk to restore full dry matter intake. It is also important to note that the cost of the diet has increased $0.09 per cow because of the lower concentration of forage in the diet. The economic reality is that daily measurement of moisture in wet ingredients has a high return.

With the cornerstone of managing moisture changes in place, let’s start building the rest of the foundation and look at the measurement of other key nutrients. When samples are collected and sent to the laboratory, there are two different measurement systems that can be used: wet chemistry and near infrared spectroscopy (NIR).

Wet chemistry uses different chemical reactions and measurement devices to measure specific nutrient components of the feed being analyzed. For example, to measure protein we measure the nitrogen content of the ingredient. NIR is a prediction-based system that shines a light on the sample and measures the light waves that reflect off. These reflected wave lengths are then compared with hundreds of other samples in a database through calibration equations that then predict the nutrients contained in the sample. It is critical to understand that the quality of NIR analyses is absolutely dependent on the quality of the wet chemistry analyses that were used to develop the NIR calibrations.

NIR nutrient analysis gives us two distinct advantages: time and money. Wet chemistry requires many days to complete, depending on the nutrients you want to measure. Once the sample is prepared, an NIR scan takes seconds and can predict any number of nutrients that calibrations have been developed for. Cost of an NIR analysis of a sample is typically 20 to 35 percent of the corresponding wet chemistry analysis. If the nutrient content of ingredients is consistent, this can reduce the cost of sampling. If the nutrients are inconsistent, you can run more samples to better manage the nutrient variation.

For any laboratory result it is important to understand the concept of accuracy versus precision.

Think of the nutrient we want to measure (i.e., protein) as a bull’s- eye on a dart board. If you threw three darts, accuracy measures how well the average of the darts reflect the bull’s-eye. Precision is all about grouping the darts close together. Accuracy without precision would be like throwing three darts in the outer ring that are equally spaced. When you average them together, they equal a bull’s-eye. Precision without accuracy would be a tight grouping away from the bull’s-eye. Our goal is accuracy with precision, which would be like hitting a bull’s-eye with all three darts.

Like throwing darts, laboratory measures (including wet chemistry) have variation. Wet chemistry provides the target we are shooting for when creating NIR calibrations. NIR can actually be more precise than wet chemistry when analyzing the same sample multiple times.

A quick look to the future shows why it is important to understand this concept. Farm-level NIR systems are being developed. Think about the benefit of pulling your daily forage sample and running it through an NIR system. You would dramatically cut down the time needed to get the moisture content for adjusting your TMR mix at the same time you get a nutrient profile of your ingredient. Monitor the variation from day to day and you can now proactively manage nutrient changes instead of waiting for the cows to tell you something is changed and you need to rebalance the diet. Now that’s precision nutrition. PD

Mike Jerred is a global dairy leader withCargill Animal Nutrition. Email Mike Jerred.