You may have noticed that you are losing oil but you don’t know where – all you know is that the five gallons you put in your tractor is all but gone. You don’t have an obvious leak under the tractor when it’s parked, but there is some oil in the back where the implement is hooked up. Is that oil just from connecting and disconnecting the implement or is it a bigger problem? If there are no other apparent leaks then it could be the coupler or O-ring that is damaged.

The O-ring is a special piece that is important in maintaining a seal. There are many O-rings in farm equipment and machines in general. There are two types of O-rings: dynamic and static. Static O-rings are under pressure and the housing or environment doesn’t move, like the rubber ring that goes under a toilet when it’s installed. Dynamic O-rings have movement as well as pressure, like cylinders and couplers. In farm equipment, the most common O-ring is in the housing where implements are connected. The material that makes up the O-ring conforms to the space as hot oil, under pressure, passes over it – creating a perfect seal.

However, this material that is durable under pressure can easily be torn and broken if dirt and coarse metal are rubbed against it. If the coupler gets dry or chipped, it cuts and chips that O-ring. So every time you lift or put the implement down, oil leaks out. Then you have to put new O-rings and backup rings in there to seal that off. You can avoid the cracking and chipping by keeping the coupler clean and lubricated. If the coupler is not clean when you connect it to the tractor, you not only scratch or damage the O-ring, you also put debris and particles into your hydraulic system.

When couplers are not taken care of, they can develop burrs or abrasive edges. These can be fixed with some 320 (or smoother) emery paper or really fine sandpaper to polish those nicks off the couplers and make them smooth, or replace the couplers altogether. Then you will want to make sure your O-rings will work properly by replacing them.

Replacing the O-ring

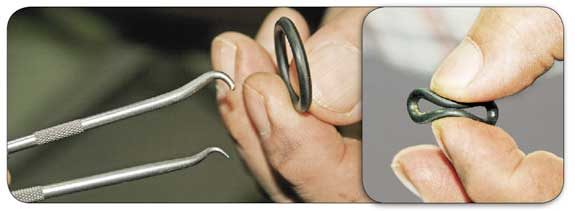

There are many ways to replace O-rings. This is the way that I have always done it. You use the special tools that come along with the O-rings that look like dentist tools.

• First you use the sharp side of the tool to pick the O-ring out of the bore inside the connector.

• Then take the new O-ring and pinch the sides together; this will cause the top and bottom to curl, and push the O-ring inside the opening of the connector.

• Using the dull pick – taking care not to tear the new O-ring – push the ring into the bore.

There are different types of O-rings. Make sure you have the right ones. Ask your hydraulic equipment dealer which rings work best for your connection. PD

Send in your mechanical questions to ryan@progressivedairy.com to have them answered in this column.

PHOTOS

ABOVE: Take care to use the sharp pick to pull the ring out and the dull pick to push the new O-ring.

ABOVE-RIGHT: By pinching the sides, the O-ring can easily slide into the connector. Photos by Ryan Curtis

-

Jim Schlund

- Retired Diesel

- Mechanics Professor

- College of Southern Idaho