Dairy producers are keenly aware of the importance of feed and feed management. Your choices of what and how to feed affects profitability. You know and understand the importance of feed uniformity. To get consistent performance, all producers strive to formulate a uniform mix of all the necessary nutrients, like protein and fiber, for optimum cow nutrition. What do ration balancing sub-models add to all the facts you already know?

Ration balancing programs are a way for dairy producers to make the most of their on-farm and opportunity ingredients. Ration balancing maintains optimum cow nutritional balances for milk production, health and reproduction, thereby maximizing genetic potential. You can also evaluate your current and proposed feeding programs with multiple rations and side-by-side comparisons of rations using ration balancing software.

Working with a dairy nutritionist or feed specialist allows you to further fine-tune your rations using ration software sub-models. Ration balancing computer programs take advantage of physiological cow models, allowing your nutritionist to dig deep into the components of a cow’s metabolism and nutrient digestion.

Ration balancing software sub-models can help you:

- Save money

- Meet specific production goals

- Balance rations for animal groups

- Take advantage of opportunity ingredients

- Evaluate fatty acids

- Check amino acid availability

Here are some examples and explanations on how to optimize your ration balancing programs.

Effective ration balancing programs incorporate nutritional sub-models that understand cow nutrition and a cow’s complex digestion system. The models accurately predict cow requirements within a broad range of feeding situations and a large base of ingredients. And sub-models further define production goals, opportunity ingredients, fatty acid profiles and amino acid availability.

Do not let your profitability and production be limited by ingredients and costs. Work with your dairy nutritionist and a reliable ration balancing program to take advantage of ration sub-models on your dairy. PD

-

Essi Evans

- Dairy Nutritionist/Model Adviser

- Dalex Livestock Solutions

- Email Essi Evans

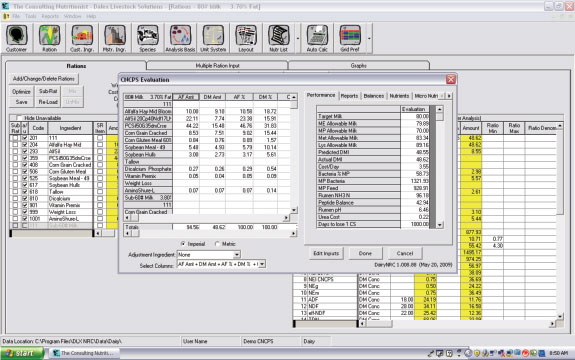

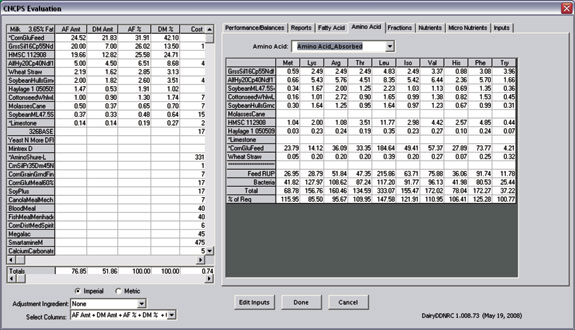

Diagram 1 – CNCPS ration evaluation

Great ration balancing means the proposed diet will meet the targeted production. The box labeled CNCPS Evaluation lists the ingredients that the ration model selected to meet the targeted production. The box on the right shows the target milk production (80 pounds). This model screen shot demonstrates that this particular diet’s dry matter intake (Predicted DMI) compares favorably with the actual dry matter intake (Actual DMI). With this formulation, your cows won’t be given excessive amounts of protein that would be wasted in urinary nitrogen output, saving money on protein and preserving the environment.

Let’s take a look at how sub-models and careful data entry can help you refine your rations, help you maintain production and use your on-farm ingredients.

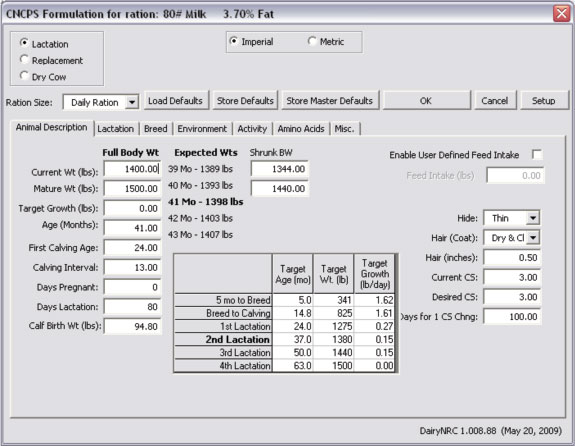

Diagram 2 – Data entry

CNCPS Formulation for 80-pound Milk Ration balancing software allows producers and nutritionists to set specific milk production goals. To reach an accurate ration prediction, the nutritionist first inputs feed, cow and management information specifically related to the dairy. With input of specific cow and dairy stats, the ration can be custom designed to fit that group of cows for that dairy with a specific production goal.

The top left box in the picture above allows the nutritionist to indicate if the ration is for lactating cows, replacement heifers or dry cows. In the animal description, the nutritionist enters the average age, weight, days in milk, calving age, gestation days and lactation days to further refine ration parameters. The nutritionist can also add breed information, as well as milk production and milk composition.

In addition, environmental conditions like heat or cold stress may also be entered. Even the energy your cows use to move around can be entered in the Activity tab. Entering all your dairy’s information, up front, with care, forms a base that allows the nutritionist to optimize rations that best meet the individual needs of not just your dairy, but of each of the animal groups on your farm.

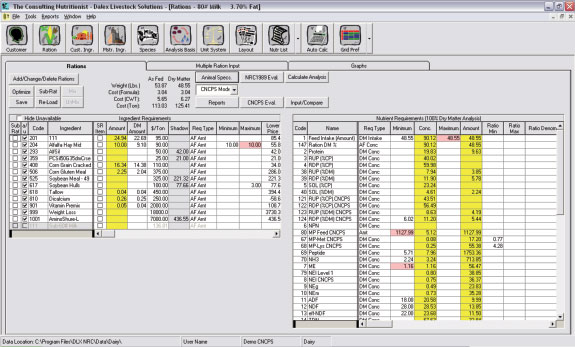

Diagram 3 – Balanced rations

As part of the base of information, the nutritionist enters all your available ingredients. Then the ration can be balanced for best cost. The nutritionist can then quickly assess which ingredients are limiting the level of performance expected from the ration.

Another feature of this particular ration balancing software is shadow pricing. This feature quickly reveals ingredients that can become ingredient opportunities, allowing producers the chance to take advantage of plentiful or low-cost ingredients.

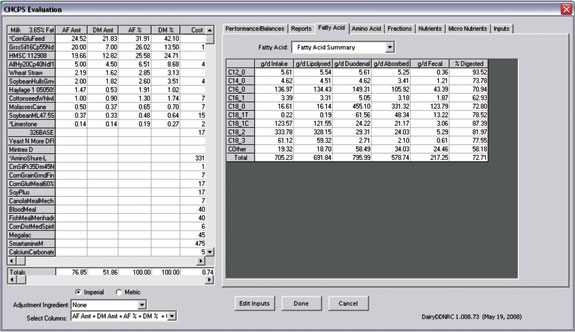

Diagram 4 – Fatty Acids

Very minute amounts of fatty acids, the building blocks of fats, have important effects on rumen and animal health. The fatty acid sub-model allows the nutritionist to take full advantage of the information available, and to better ensure no adverse effects of fat upon rumen health or milk fat production. Fatty acids also contribute to health and reproductive performance and can be given close attention by the nutritionist.

Diagram 5 – CNCPS Evaluation Amino Acids Absorbed

This fine-detail screen shows amino acids and protein components. The nutritionist can see where the amino acids originate and the types of ingredients that might actually improve the amino acid balance if they were made available in the ration.

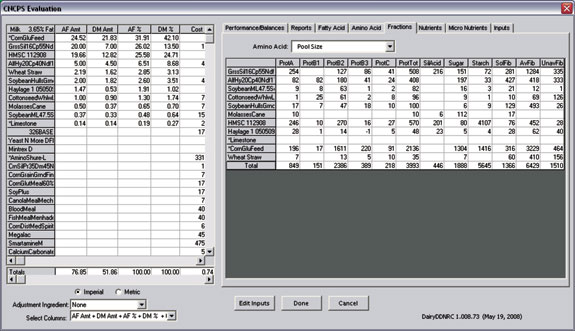

Diagram 6 – CNCPS Evaluation Pool Size

This ration balancing sub-model screen demonstrates even further ration detail. Here the nutritionist can view individual feed fractions for proteins and carbohydrates. This data provides details on which ingredients contribute to the individual pools, and are helpful in determining where limitations are occurring within the current ration.