Teat-cup liners are one of the most important pieces of the milking system; it’s the only component in direct contact with live tissue. Choosing the right liner for your herd can be a difficult and confusing decision.

When considering a new liner, keep your dairy’s goals in mind. Are you changing liners for udder health reasons? Faster milking? Better overall performance?

When udder health issues arise, liners are often the first component of the milking system to be changed. Since liners need to be changed regularly anyway, it’s a change that almost always eliminates any additional costs. The reality, however, is: Changing liners is not always the silver bullet one hopes. Often, there are milk quality issues other than the liner to consider.

Selecting the right liner for your herd can be an overwhelming decision, and it should take into account many aspects of your farm, your herd and your management style. It is important to understand the various options available in today’s market to make the best decision for your dairy.

Liner shape

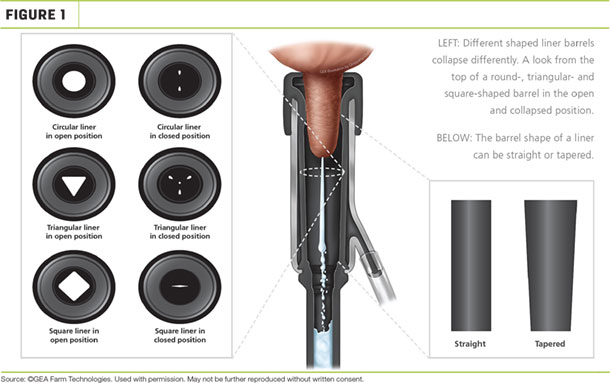

Liners come in many shapes: round, square, triangle, tri-circle, oval and variations of all of these (Figure 1).

Tapering the barrel has also become popular. While shaped liners often get credit for improving teat-end condition, setting the liner up for optimal performance is often the deciding factor (i.e., setting proper vacuum levels and pulsation specifications).

Teat size

Consider the average teat size for the cows on your dairy. Using a narrow-bore liner on large teats will result in poor milking performance. The use of a medium-bore liner may offer the best all-around milkability for the majority of your herd.

Liner material

Choosing a liner material should depend on how long you want the liners to last and your dairy’s desired performance properties. Liners can be made of rubber, blends of both natural rubber and synthetic rubber, and silicone, among others.

- Synthetic rubber or mixtures of natural and synthetic are more resistant to breakdown from butterfat absorption and will tend to have a longer milking life than natural rubber liners.

- Silicone liners have a longer milking life, are resistant to butterfat absorption and are more consistent in milking performance throughout the liner’s life.

Liner changes

Liners need to be changed out regularly due to use. They should be replaced after a specific number of cow milkings – which can vary from as few as 800 milkings to more than 10,000 – depending on the liner material.

Cleaning cycles also impact liner wear. Standard rubber liners may begin to degrade after 80 to 100 wash cycles with material blends, while silicone liners last through more cleaning cycles.

Liner vents

A majority of today’s liners are offered with vents to help keep milk movement away from the teat. Placement of the vent can be in the mouthpiece or milk tube, with an additional vent in the milking claw. Any combination of these vents can help aid in faster milk flow from the teat to the milk hose. While vents play a key role in helping move milk, the diameter of the milk tube and milking unit inlet is also important.

Maximizing the overall milkability of a liner involves getting your milking system properly set up for the liner you’re using. Many of the liners on dairies today are underperforming simply because they were never set up properly when installed. Optimal performance of any liner is dependent on:

- Using proper average peak claw vacuum settings for your specific liner

- Setting pulsation to optimize the average “b” and “d” phases of the pulsation system

- Proper teat prep to ensure full milk letdown and flow from time of unit attachment to unit detach

- Using detacher settings for unit detach without overmilking

- Unit alignment and support

- The overall milk path from the milking unit to the receiver

Consider having a qualified milking technician or consultant perform milking-time testing according to the National Mastitis Council procedures for evaluating vacuum levels and air flow in milking systems. No liner will achieve peak performance or optimal milkability if your system is deficient.

All liner manufacturers have recommendations for liner installation and setup. Make sure whoever installs your liners are aware of setup recommendations and are capable of doing the needed testing to verify a proper install.

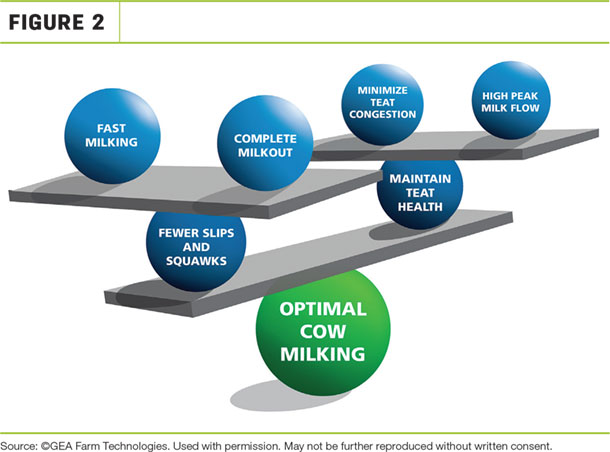

The goal is to balance your desired goals on top of optimal cow milking (Figure 2).

Once your system is properly set up for the liner you’re using, then it is up to the cows to decide if the choice was a good one. ![]()

-

Mark Walker

- Liner and Supplies Sales Specialist

- GEA Farm Technologies

- Email Mark Walker