The squeeze on dairy profitability has been getting tighter, and the length of this downturn is exhausting both the financial and emotional state of many farms. “What can I do?” is a common question. A key I have seen in my 40-plus years in the industry is that basics are the foundation of the farm profit. In spite of the technological advances in computers, GMOs, drones, etc., the basics mattered yesterday and they still do today. Highly digestible alfalfa is not helpful if you have not soil tested all the fields you work and applied amendments as indicated.

Forages are the foundation of most of the dairy industry. The ability to produce protein and energy at a cost less than what can be purchased as an outside grain is where the potential profit begins. Forages start with high potential, but what reaches the cow’s mouth is often much less than what it could be.

Those who are still harvesting by date rather than physiological stage have a major loss in first cutting haylage. John Winchell with Alltech in western New York has tracked the date of optimum alfalfa harvest based on heat units. For his location, it has ranged between May 16 and May 28 over the past eight years. Thus, only one out of the past eight years will hit close to quality if you use a date as your start point. Fortunately, key work by Dr. Jerry Cherney at Cornell has developed a system that uses the physiological maturity of the alfalfa itself to determine optimum harvest time (see www.forages.org).

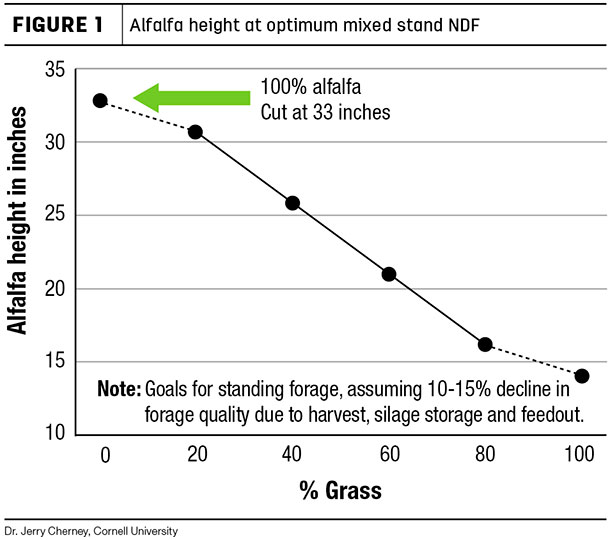

As you can see in Figure 1, by just using a ruler and noting the percentage of grass in the stand, you can determine when the optimum time to harvest is. Grass fields are ready often a week or two before all alfalfa fields. South facing fields are ready before north facing, dry fields before wet fields, but if you don’t look and measure, then you are simply guessing at quality forage harvest date, and there is no room for guessing in the dairy industry today.

How you harvest has a major impact on the time it takes and the quality saved or lost. We have been talking about wide swath and same-day haylage for nearly 18 years. Some non-wide swathed samples I recently looked at were 0.61 NEL (net energy lactation). A farm in Savannah, New York, showed me a wide swath haylage sample with an NEL of 0.71. This is almost to the energy level of corn silage. And 16 percent more energy in your haylage can go a long way in reducing the cost to achieve the same milk production. Yes, it takes some effort to figure it out for your farm. You may have to make some changes on your mower to get a swath to greater than 80 percent of cutter-bar width. The biggest problem is between the ears – you have to change “what we always did!” The money is on the table; it is up to you to pick it up.

We have been talking about winter triticale and other winter forages for nearly 20 years. It is at the level where the entire package has been researched and sound recommendations are available. Pulling off 2 to 4 tons of dry matter (5.7 to 11 tons of silage) before you even grow your regular crop that year is a nice addition. This pales, though, against the very high forage quality winter forage has been producing.

Crude protein of 20 percent and NEL of 0.75 is huge in reducing the cost of producing the milk you sell. Multiple farms are growing it solely to put in the diet when temperatures turn hot and “summer slump” drops milk production. With properly fertilized and harvested winter triticale, production holds and summer slump becomes a thing of the past – putting profit back where there was a loss.

As we follow the forage to the cow, shortcuts and “savings” are eating into the milk producing ability of the feed you grow, harvest, store and feed. If you had a field that needed to be seeded again, do you lime, fertilize, work up a perfect seed bed, roll it to push the stones down to make it smooth, and then walk away and let whatever might grow be the crop you harvest? If you are harvesting very high quality forage at Cherney’s optimum stage, using same-day wide swath to enhance energy, chop at optimum moisture, pack it well in the silo and then let whatever garbage bacteria, fungi and mold floating around in the air and on the soil ferment your crop – it is no different.

For making cheese, yogurt, ethanol and other fermented products, the bugs doing the job are carefully selected for optimum results – so it is with silage. I conducted a controlled, replicated trial with American Farm Products (I have no financial relationship; I questioned their product and we all wanted to get to the bottom of what I was seeing in research, so we ran a controlled experiment). Using the inoculant with a proper water carrier (chlorinated water will kill the bugs) compared to the control with no inoculant, the enhanced fermentation preserved more digestible material to equal 2.3 more pounds of milk per cow per day.

Finally, check your feedout details. I was once on a farm where after morning feeding we shoveled up sufficient loose forage to make 110 percent of the afternoon ration. Loose forage at the end of feeding will spoil and burn off a considerable amount of the quality in the last step before it reaches the mouth of the cow. The farm switched from having loose feed left to having none. On 200 cows, from Thursday when he made the switch to Tuesday when we again reviewed the farm, he was up 2 pounds of milk per cow per day. Ultimately he went up 5 pounds of milk per cow per day with this one simple change.

Little things make a difference, especially when we are dealing with the basics. ![]()

This ran in the February 2018 Crop Soil News newsletter from Advanced Ag Systems.

Tom Kilcer is a certified crop advisor with Advanced Ag Systems. Email Tom Kilcer.