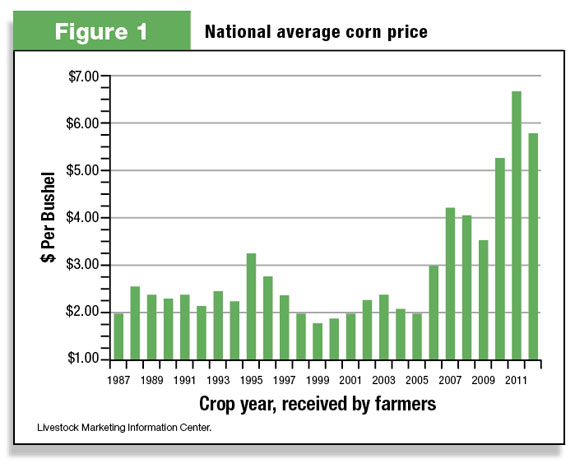

Recent developments, however, have moved feed costs into uncharted territory. Figure 1 shows the national average corn price since 1967.

Basically, the figure illustrates 40 years of $2 corn. Experienced livestock producers likely became quite comfortable with these costs and with the relationship between year-to-year feed cost fluctuations and the cost of production.

As the chart shows, 2007 brought a new plateau in feed (corn) costs, which have continued to increase. Also note the increased variation and volatility. These appear to be the new rules of feed cost economics.

Corn: No longer the low-cost feedstuff

Perhaps the most dramatic change that has occurred during this time period is that corn is no longer the lowest-cost source of feed energy.

For much of the past 100 years, the best cattle feeding ration has included corn, home-grown forage and a complete protein-based supplement. Today the best options are more local and may change from year to year.

To be the low-cost producer today takes a new approach to management of feed, ration and cattle. Here are a few suggestions for cattlemen to consider as they develop their feeding programs for the upcoming year.

Identify feedstuffs. Look out of the box. Today the first step in beef ration development is to identify the feedstuffs that should be considered.

Surprisingly, often the best bargains are the feeds that are most local, especially those only you and a few neighbors know about or have access to.

- Check out these very local opportunities first. Some examples of these types of feeds that may be available are corn screenings from the local elevator, slightly damaged or off-grade corn from your cash corn neighbor, husklage from the local seed corn processing plant or byproducts from local food and feed processors. Give your cattle the opportunity to be “locavores” if there is an economic opportunity.

- The next feeds to consider are those limited in their market by moisture levels and transportation costs. In Iowa, these include modified distillers grains, wet distillers grains, wet corn gluten feed and condensed distillers solubles (syrup.)

- Finally, consider dry commodities that may be available. These feeds can be great bargains but those bargains can disappear quickly because they are global commodities. Examples include dry distillers grains, soy hulls, corn gluten pellets, wheat midds and whole cottonseed.

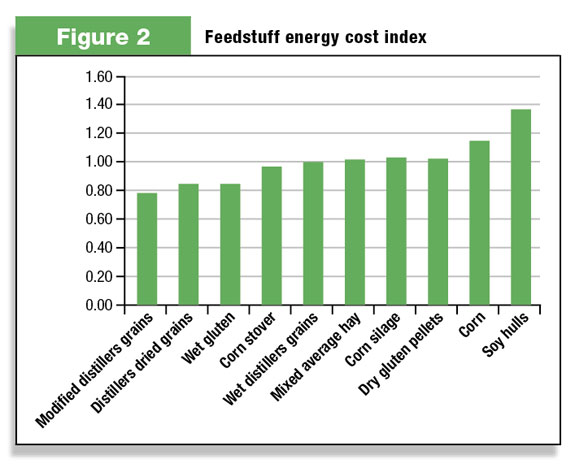

- Figure 2 is generated by the feedstuff energy cost index program, a free download from the Iowa Beef Center (http://www.iowabeefcenter.org/Software/FeedEnergyIndexNE.xls).

The example here was from average prices published on Sept. 12, 2011. The prices were taken from the Iowa Ethanol Report, the Missouri byproduct feed price listing and the Iowa Hay Report.

Of course, you should use your own delivered prices, but this example shows modified distillers grains as a feed that should be strongly considered for any ration formulation.

Corn stalks and medium-quality hay are lower in cost than corn silage (at $71 per ton). At $7.10 per bushel, corn grain is one of the most expensive available feedstuffs.

Harvest corn stover. The national forage production is well below average. This is due to the historic drought conditions in the Southwestern U.S.

Also, it appears that winter wheat grazing will be limited as well due to dry conditions in Oklahoma and Kansas. Corn stover is a practically unlimited resource that is widely available.

While this feed alone will not meet the nutrient requirements for most classes of cattle, it can serve as a base for a properly supplemented feeding program.

Balance rations. One of the major challenges of the new reality for feedstuff selection is that the most economical feeds will likely be quite variable in nutrient composition and/or need significant supplementation to meet the requirements of many classes of cattle.

This requires producers to have a good relationship with suppliers. Routine feed testing and monitoring, along with complete ration balancing, is more important as feed costs increase.

If you want to tackle the ration balancing on your own, consider a computer program such as the BRaNDS program from IBC. Many of you will look to professional assistance from a nutritionist for help.

Lock in feed supplies and prices. Many ethanol producers offer forward contracts for MDG and WDG supplies and prices.

If these feeds work out to be the most economical of the available feeds, this may be an option to consider.

Also, with the volatility in feed, feeder and fed cattle prices, some protection of margins may be prudent when the opportunity arises.

Reduce feed waste and shrink. When feed costs are high, reducing feed storage and feeding waste can pay big dividends.

For cow operations, utilization of waste-reducing bale feeders or making the switch to a total mixed ration (TMR) is worthy of consideration. Also, investment in feed storage systems that reduce waste, such as a commodity shed, can reduce waste and shrink significantly.

For all producers, it is very important to inventory and weigh feed in and out of storage. The first step in improving feed shrink and waste is knowing what the baseline level is by feedstuff and storage unit.

Be efficient. Feed efficiency becomes increasingly important as feed costs escalate. Technologies that improve feed efficiency should be fine-tuned.

Be sure to talk to your veterinarian, nutrition consultant or extension beef specialist about your implant program options that optimize efficiency.

Also, if you are not currently using a beta agonist, learn more about these newer technologies. For beef cow operations, are you feeding an ionophore to your cows? Don’t forget to review your health management and parasite control programs to make sure they are state-of-the-art.

In today’s economic environment, successful cattle producers are the ones who are flexible and adaptable in feed procurement. Once the feeds are sourced, however, efficiency and consistent management continue to be of utmost importance. ![]()

—Excerpts from Iowa State University Growing Beef newsletter, October 2011

Dan Loy

Director

Iowa State University

– Iowa Beef Center

dloy@iastate.edu