It’s not uncommon to observe dump trucks, a maintainer and a dozer or two. When my tour guide is asked why they have all this construction equipment, the answer is usually, “We built the ranch roads two years ago and bought it then” or “A road-building company went out of business and we purchased their equipment at a very low price. We will need it some day.”

Leasing equipment or hiring work done may be better options than buying machinery that will be used only a few times during a year.

Dr. Jason Banta of the Texas A&M AgriLife Extension Service discussed ways to reduce equipment expense at the 2013 Next Generation Agricultural Conference in Bryan, Texas. Most of the information in this article is taken from his presentation.

Banta suggested asking yourself the following questions before buying equipment:

- Will it help me accomplish my long-term goals?

- What is the availability of capital money?

- What is the availability of operating dollars?

- How often will I use the equipment?

- Can the equipment be used for multiple purposes?

Your answers to the above questions should guide the decision of whether to buy equipment. Lease or rental is a good alternative if purchase cannot be justified.

Hiring someone to complete the task is sometimes less costly than buying the necessary equipment to do the job yourself.

Routinely owned ranch equipment

Routinely owned ranch equipment listed by Banta includes a pickup, stock and flatbed trailers, welders, a tractor with a front-end loader, all-terrain vehicles (ATVs) and a skid-steer. The items on this list may not be needed, justifiable or frequently used.

If the pickup is used only on the ranch, does it need to have an extended cab, be the latest model and be equipped with all the available extras?

A fully equipped 2013 GMC pickup with an extended cab will cost approximately $53,000. A similarly equipped 2003 Chevrolet extended-cab pickup can be purchased for approximately $15,000.

You save $38,000 by buying a 10-year-old pickup instead of a new one. A lot of repair bills can be paid with $38,000. If a new pickup is justified, the cost of leasing should be explored.

A gooseneck stock trailer is probably not necessary if you only haul cattle to market once or twice a year. Used 16-foot, 24-foot or 32-foot trailers in good condition will range in price from $8,000 to $13,000.

Save input costs by renting or hiring someone to haul cattle for you. It is a good idea to own a bumper-pull stock trailer with a four-cow or five-cow capacity so that you have a way to haul sick cattle to the veterinarian.

Unless you are in the custom-farming business or manage scattered blocks of land, a gooseneck flatbed is probably not justified.

A used 35-foot to 40-foot flatbed trailer ranges in price from $2,500 to $9,000. If the trailer is only used to haul equipment to the dealer for repairs, it would be less costly to have it hauled for you.

Another cost associated with large gooseneck trailers is that a 1-ton truck is usually required to pull them.

The ATV is America’s new horse and is very fuel-efficient. Additionally, an ATV doesn’t require any amount of fuel unless it is being used. A horse has to be fed whether it is working or not.

ATVs can be used for multiple purposes – stretching fence wire, checking cattle, carrying feed, running errands and many other chores. One of its advantages over a tractor or other large vehicle is that an ATV can drive into smaller spaces.

Welders are commonly found on ranches, and it is usually learned that they are used only a few times a year.

It would probably be more cost-efficient to hire a welder when his services are needed. Welders can also be leased or rented for the duration of the job and then returned.

If the ownership of a tractor is justifiable, purchase one large enough to handle required tasks. A tractor that is too small for the job is inefficient and unsafe. A front-end loader usually adds versatility to a tractor.

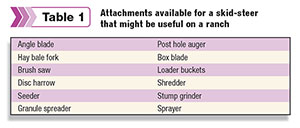

A skid-steer may be more usable than a tractor because of the available attachments that can be purchased.

The attachments that might be useful on a ranch are listed in Table 1.

Manage assets to improve profits

One of the biggest input costs that reduce ranch profits is depreciation of hay-harvest equipment.

This equipment usually includes a mower, conditioner, rake, baler, at least two tractors, hay forks and trailers. It is hard to justify this much equipment unless you are in the custom hay harvesting business.

Always lease farm or hay equipment if at all possible. The best way to avoid these expenses is to avoid harvesting hay.

When and where possible, let your cows harvest the hay while it is standing in the field. Consider purchasing hay needed during the cold part of winter instead of trying to produce it yourself. Above all, try not to practice recreational hay baling.

Regardless of the type of equipment, buy only what you will use enough to justify the initial expense. Equipment purchases can be reduced by the following alternatives:

- Lease rather than buy if it is cheaper.

- Rent what you can as you need it.

- Hire custom operators.

- Focus on things that make you money.

The only exception to the above rules may be an herbicide sprayer because they are often not available when it is time to spray.

Most of us enjoy buying and operating equipment. To keep the ranch profitable, however, we should refrain from buying equipment just to admire it and proudly show it to our neighbors. ![]()

Robert Fears is a freelance writer based in Texas.