Many of us have probably worked on ranches where you had to act tougher than the cattle or you would be mauled.

Whips, electric prods and lariats were common tools, and if you could holler with a lot of volume while waving your arms, you were considered a good cowhand.

Cattle and men were usually injured during each roundup as a result of these handling techniques. Finally, we realized that rough handling of livestock reduces profits and as a result, most ranches currently manage cattle under low-stress conditions and cull temperamental animals.

“Safe and effective cattle handling has always been important,” says Ron Gill of the Texas A&M AgriLife Extension Service. “In the last few years there has been a move toward what has been called low-stress handling, or as we prefer to call it, a return to sound stockmanship.”

Documented benefits from feedlots

“Reducing stress during handling will provide advantages of increasing productivity and maintaining meat quality,” says Temple Grandin, professor of animal science at Colorado State University.

“Recent work in our laboratory has indicated that when cattle become agitated and excited in the squeeze chute, they have significantly lower weight gains, tougher meat and more borderline dark cutters.

Agitation and excitement are influenced by both genetic factors and the animal’s previous handling experiences.

I have observed that cattle with previous experience of quiet handling will be calmer and easier to handle in the future.

“Anecdotal reports from commercial feedlots indicate that quiet handling methods help improve productivity,” Grandin continues.

“Deaths due to respiratory sickness were greatly reduced in a Texas feedlot when quiet handling procedures were implemented. Handlers moved cattle quietly at a walk both in the processing facility and in the yard.”

Lee Reeve, manager of Reeve Cattle Company in Kansas, reports that eliminating electric prods in the processing area enabled re-implanted cattle to get back on feed faster.

Bud Williams, a cattle-handling expert in Alberta, Canada, states that lowering stress during receiving at the feedlot reduces medicine costs.

Bud Williams, a cattle-handling expert in Alberta, Canada, states that lowering stress during receiving at the feedlot reduces medicine costs.

At another feedlot, toe abscesses were reduced by half when quieter handling methods were used.

One cause of toe abscesses is scuffing of the toes when agitated cattle are waiting in line in the chute.

“Short-term stressors that occur during handling and transport have been shown to interfere with biological mechanisms of both reproduction and immune function,” reports Grandin.

“Electric prods, restraint and other handling stressors will lower female reproductive function. In both pigs and cattle, transport or restraint stress lowers immune function.

In cattle, the stress imposed by transit has a greater detrimental effect on the animal’s physiology than the stress of feed and water deprivation for the same length of time.

Transport stress can also lower rumen function compared to controls subjected to feed withdrawal.”

Stress causes shrink

Stress causes weight shrinkage that is particularly noticeable during processing, transporting and marketing. Reducing stress placed on cattle during these times will help reduce marketed cattle value losses caused by shrinkage.

“Just the act of weighing cattle causes some shrinkage,” the Ontario Ministry of Agriculture and Food reports. “Calves can lose 3 percent of their weight during sorting and loading.

Every 30 minutes spent moving cattle around in handling facilities will reduce their weight by 0.5 percent. Use quiet handling methods for moving and processing cattle to lessen this effect.

Well-designed handling facilities will allow animals to be processed quickly while experiencing minimal stress.

“Do not yell or whistle at cattle. Avoid the use of electric prods, canes, whips and dogs. If not all animals are to be sold, then sort cattle one to two weeks before weighing and marketing.

Design facilities to allow cattle to move directly onto trailers without any delays after they have been weighed.

“Compared to cattle standing in a pen without feed and water, transported cattle will shrink 2 percent more over the same time period,” the ministry says. “For the first three to four hours during travel, cattle lose 1 percent of their weight per hour.

Over the next eight to 10 hours, they lose 0.25 percent per hour. Cattle lose an additional 0.61 percent of their weight for every 100 miles they are shipped.”

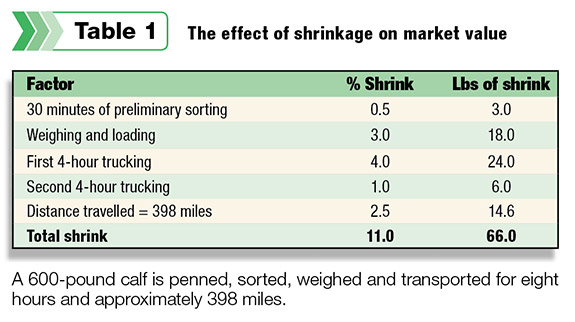

The ministry uses the example in Table 1 to illustrate the effect of shrinkage on market value.

The total shrinkage shown in Table 1 is 66 pounds. In today’s markets, it is not uncommon for feeder calves to sell for $1.35 per pound.

At this price, the 66-pound shrinkage would have been a lost value of $89.10 for one calf.

So it pays to reduce stress during shipment as much as possible, and low-stress handling is the place to start.

If the 600-pound calf is lost due to a stressed dam failing to calve or becoming diseased because of immunity reduction, the total lost value could be $810 at today’s prices.

Reducing animal stress by not abusing cattle pays big dividends and is important for the profitability and longevity of the ranch. ![]()

Robert Fears is a freelance writer based in Texas.

PHOTOS

TOP: Cattle stress can be reduced during marketing by delivering them to the sales facility the day prior to the sale.

TOP MIDDLE: Move cattle through corrals slowly and quietly to eliminate the potential stress to animals.

MIDDLE: Corrals should be designed to reduce stress on cattle and employees.

BOTTOM: Shrinkage occurs during transportation of cattle due to stress. Photos by Robert Fears.