However, a couple of factors may be bringing cattle feeding back to the Corn Belt: availability of low-cost wet distillers grains and confinement finishing facilities.

The ethanol expansion during the 2000s led to increased use of distillers grains in feedlot diets as a replacement for high-cost corn. Wet distillers grains can be included in diets at greater amounts than dry distillers grains (40% versus 20% of diet dry matter) without negatively impacting rate of gain. Therefore, feedlots closer to the plant can gain an advantage in feed cost. Additionally, there appears to be a greater advantage to including wet distillers grains in dry-rolled corn diets, which is the primary processing method used in the Corn Belt, compared with steam-flaked corn diets used in larger feedlots in the High Plains. The availability of wet distillers grains in the Corn Belt allows feedlots in the region to reduce feed costs.

A more recent trend is the use of modern total confinement finishing facilities. Feeding cattle in the Corn Belt has several environmental challenges, such as mud and cold stress during winter and heat stress in the summer. As little as 4 inches of mud can decrease feed intake by 10% to 15%, resulting in reduced rate of gain.

Temperatures below freezing increase feed used for maintenance by 10% for each 10-degree drop in temperature, and cattle that are wet and covered with mud have a 40% increase in feed used for maintenance with each 10-degree drop in temperature below freezing.

High humidity during summer months decreases the ability of cattle to cool themselves by panting, and nighttime temperatures above 70ºF with high humidity can result in as much as 35% reduction in feed intake, resulting in reduced rate of gain. Total confinement facilities are designed to improve the environmental conditions cattle experience by reducing mud, keeping cattle dry and providing total shade to reduce heat stress.

Data from under a roof

Early research evaluating confinement barns in the 1970s and 1980s found that cattle in confinement barns consumed 4.5% less feed and converted feed 2.7% more efficiently. However, the accompanying reduced rate of gain increased days on feed, making the confinement barn less attractive. The reduction in feed intake was thought to be due to lack of ventilation and air flow through the barn, as these barns had a gable roof and walls on three sides.

However, modern confinement facilities such as hoop and monoslope barns have improved design features to allow hot, humid air to rise out of the barn and improve air flow through the barn. Recent research has reported similar feed intake but improved rate of gain and feed efficiency in modern confinement barns compared with cattle in open lots.

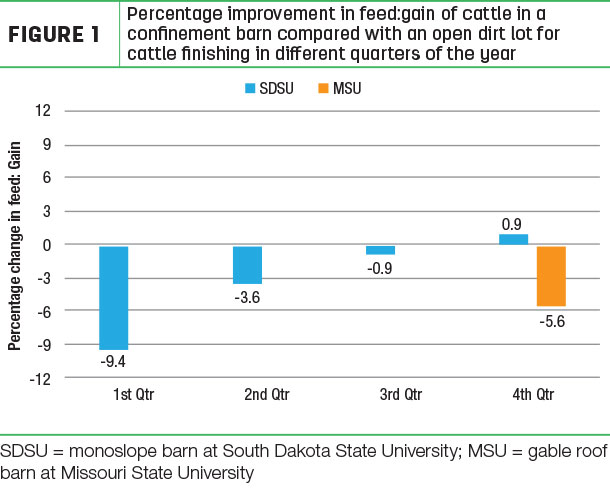

Research at South Dakota State University reported that cattle in a monoslope barn converted feed 3.5% more efficiently over a seven-year period. However, there were considerable differences between seasons in which the cattle finished with the greatest advantage in the first quarter (Figure 1).

This is likely due to the reduced impacts of mud and cold stress during this time of year. In the third and fourth quarter, there was very little advantage for the confinement barn, likely due to relatively good environmental conditions in the open lot during this time of year. Additionally, it is much easier to reduce the negative effects of mud and cold stress by keeping cattle on concrete, under roof and out of the wind than it is to alleviate heat stress.

At the southern edge of the Corn Belt, winters are less severe, but summers are longer and more humid, suggesting confinement barns may be less beneficial than in the northern Corn Belt. A recent two-year study at Missouri State University in Springfield, Missouri, compared performance of cattle in a gable-roof confinement barn and an open dirt lot. Cattle went on feed in early July and finished in December each year.

In southwest Missouri, the prevailing summer winds come from the south or southeast, but can come from any direction on a given day, creating inconsistent air movement in a barn with sidewalls. Thus, to improve air movement in the barn, some design modifications were made to the standard gable-roof barn such that sidewalls were removed and high-speed wall-mount fans were installed to provide consistent air flow even on calm days.

Averaged across the two years, cattle in the barn converted feed 5.6% more efficiently. Based on observations during the study, the improved feed efficiency is likely mostly attributable to the installation of fans in the confinement barn.

In conclusion, changes in feedstuff availability and new confinement facility design may improve the economics of cattle feeding in the Corn Belt. However, the benefit of a confinement barn is dependent upon the climate of the region, and producers need to evaluate the potential improvement in cattle performance for their particular situation. In the southern Corn Belt, the greater risk of heat stress suggest that including fans in the design of the confinement barn to improve air flow can enhance cattle comfort and performance. ![]()

PHOTO: Modern improvements in confinement barns have allowed hot air to rise and improve airflow, encouraging better feed intake. Photo by David Cooper.

-

Phillip Lancaster

- Assistant Professor – Beef Cattle Production

- Missouri State University

- Email Phillip Lancaster