Most of us have had an X-ray, CT scan or MRI at some point in our lives. This type of imaging allows the medical professional in-depth insights on what may be causing an ailment or pain we feel. It also helps fast-track the diagnosis process and can find the root cause of an issue. Analysis of manure can offer us the same inside scoop on starch digestion. Instead of guessing if our cattle are utilizing starch efficiently, tracking fecal starch reveals what is going on inside the cow and helps you assess areas for improvement.

Cattle prices are looking strong to start 2023; however, cost of gain continues to increase. High feed costs are one aspect driving these high prices and keeping break-even costs high. According to farmdoc, daily feed cost of gain is expected to be around $140-$143 per hundredweight (cwt) in the first quarter of 2023, and $135-140 per cwt in the second quarter of 2023. Unfortunately, it looks like high feed prices are here to stay, at least for the first half of the year. In uncertain markets, what can be done to help increase profitability? Focusing on efficiency is a starting place. Corn is a major staple for most grower and finisher diets, with starch inclusion ranging from 20% to 60% of the ration on a dry matter (DM) basis. Although we can’t control the corn price, we can track and maximize the amount of starch utilized by cattle.

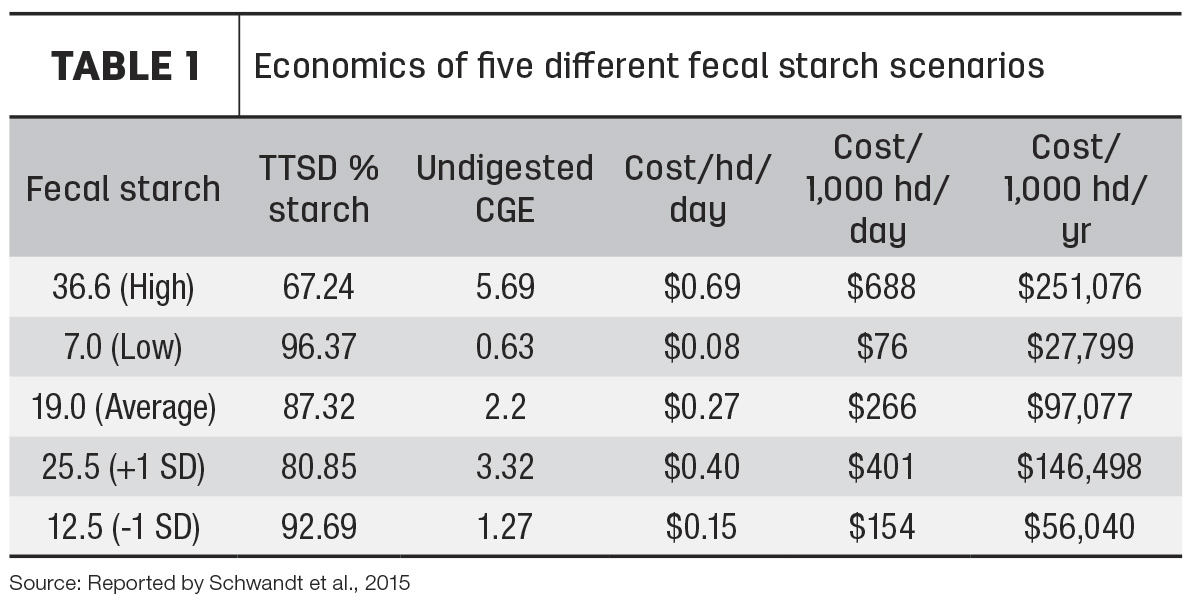

Studies have shown a relationship between fecal starch and total tract starch digestibility (TTSD). By testing starch in manure, we can gain an understanding of how much starch the cow is utilizing and how much is going undigested. The cost of this undigested starch shouldn’t be ignored. A recent survey study of 34 Midwest finishing yards utilizing dry processed corn found average fecal starch levels of 19%, with a range of 6% to 36.6%. This range is quite large, but when we assess the cost of this range, the results are jaw-dropping.

Table 1 shows the undigested corn grain equivalents (CGE), bushels and total cost associated with the change in fecal starch. Assuming 55% dietary starch as the study presented, going from the average level of fecal starch reported in the study to the lower end of the range accounts for nearly $70,000 per year with a current corn cost of $6.70 per bushel.

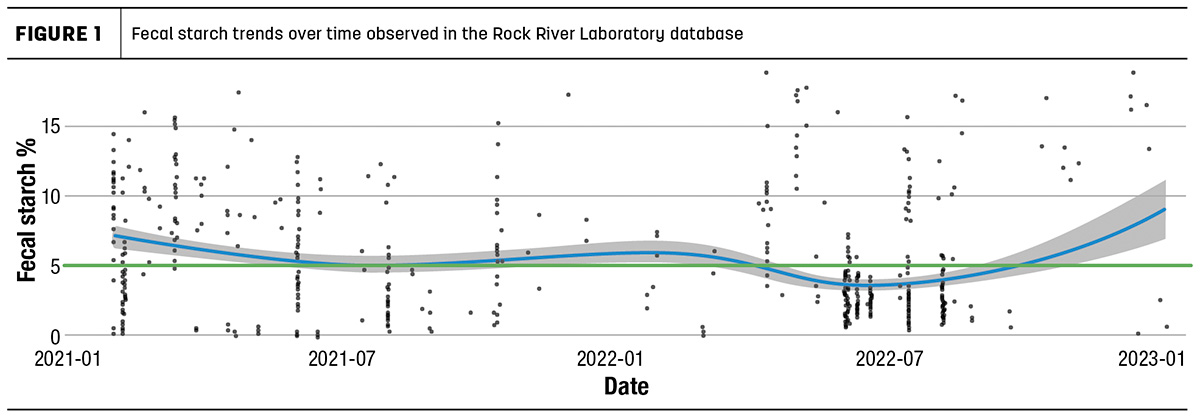

Looking at fecal starch in beef manure samples tested at Rock River Laboratory, a range of less than 1% to over 15% can be observed. This range and trendline over time can be observed in Figure 1.

Capturing the aforementioned amount of economic savings of course sounds attractive, but what tools are available to help decrease fecal starch? Various solutions exist to help move this needle.

Processing method is a huge factor in starch availability. In 2015, research from University of California – Davis' (UC-Davis) Richard Zinn and Fred Owens of Pioneer noted TTSD levels of several different processing methods for different grains. He reported approximately 90% TTSD in dry whole and tempered cold-rolled corn grain, 89.3% TTSD in dry roller corn, 92% TTSD in dry finely processed corn, and over 99% TTSD in high-moisture and steam-flaked corn.

In ground corn, examining the grind size can also help troubleshoot higher-than-desired fecal starch levels. When exploring the Rock River Laboratory database, commercially ground corn can easily measure mean particle size (MPS) below 300. Additionally, each 100 units difference in MPS equates to approximately a seven-unit difference in rumen-degradable starch, according to research from Randy Shaver and John Goeser at the University of Wisconsin – Madison. Different grains have different starch digestibilities and are impacted by different processing. Impact of processing on corn and sorghum is quite substantial when it comes to TTSD improvement, while grains like wheat and barley may be more available with limited processing.

Don’t forget about starch in forages. When examining corn silage, ensuring the ideal kernel processing score (KPS) will help to maximize the amount of starch that can be utilized by the cow. Producers should shoot for a KPS greater than 70%. Fermentation time can also have a large impact on starch digestibility. Seven-hour in situ starch digestibility (ISSD7) in fresh corn silage averages around 65%, while ensiled corn silage has an ISSD7 that can reach over 85%. Fermentation also increases starch digestibility in high-moisture grains.

Moisture content can also play a role in starch digestibility of high-moisture grains and forages. Chopping corn silage when it is too mature and dry can cause elevated ISSD7 due to increased hardness of the kernel. One study analyzing high-moisture corn found a 1.6-unit decrease in ISSD7 for every unit increase in DM in high-moisture corn samples ranging from 55% to 85%.

Ensuring feeds are being utilized efficiently is an economical way to help decrease cost of gain with increasingly tight margins on the horizon. Get an inside look at how efficiently cattle are utilizing starch with a fecal starch analysis, and assess potential opportunities while monitoring progress over time. Simple management adjustments in processing and forage harvest may be the efficiency ticket to take advantage of promising cattle prices.