Large dairies prefer liquid manure-handling systems which result in large amounts of liquid dairy manure that are typically applied via irrigation systems to adjacent croplands during the growing season. Solids and nutrients found in liquid manure pose a few challenges to manure-handling processes.

The first challenge is the high cost associated with cleaning manure lagoons. Liquid manure with high solids flows into a storage lagoon where some of the solids settle to the bottom of the lagoon, resulting in reduced lagoon capacity. Eventually, the solids at the bottom of the lagoon need to be removed to increase the lagoon capacity, which is a costly financial burden for producers.

Second, liquid manure with high nutrients (especially phosphorus) limits the manure land application rate, which means larger areas are needed to apply the same amount of liquid manure. This is a significant challenge for most confined animal feeding operations (CAFOs), which have relatively small land areas compared to herd sizes. The need to spread nutrients over larger land areas mandates the costly transportation of a large volume of liquid manure longer distances.

A third challenge is that liquid manure with high solids increases the potential for plugging pumps, transfer pipes and sprinkler nozzles. It requires more power to pump the same volume and requires higher pressure at the pump, thus increasing the risk of ruptured seals and manure spills. Separating solids and nutrients from liquid dairy manure is a critical step to improve nutrient use efficiency and reduce overall manure-handling costs.

Liquid dairy manure solid particle size distribution and nutrients associated with each group of particles

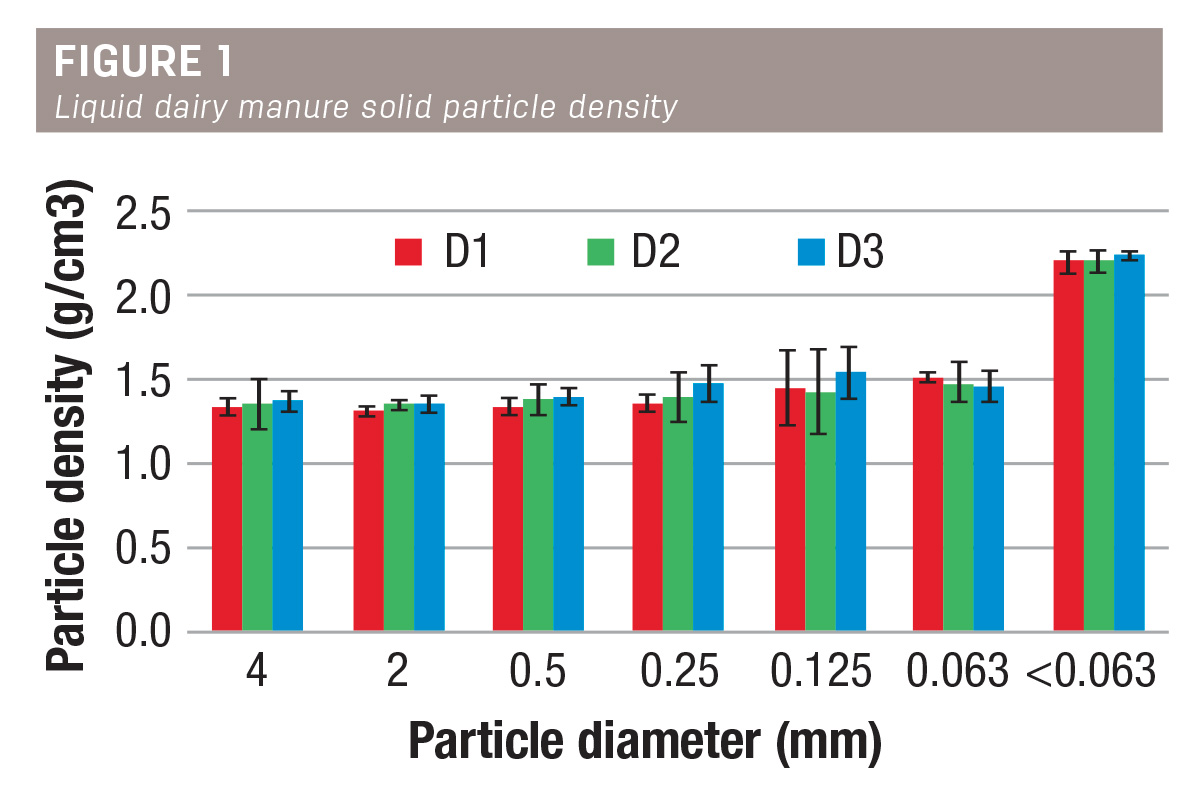

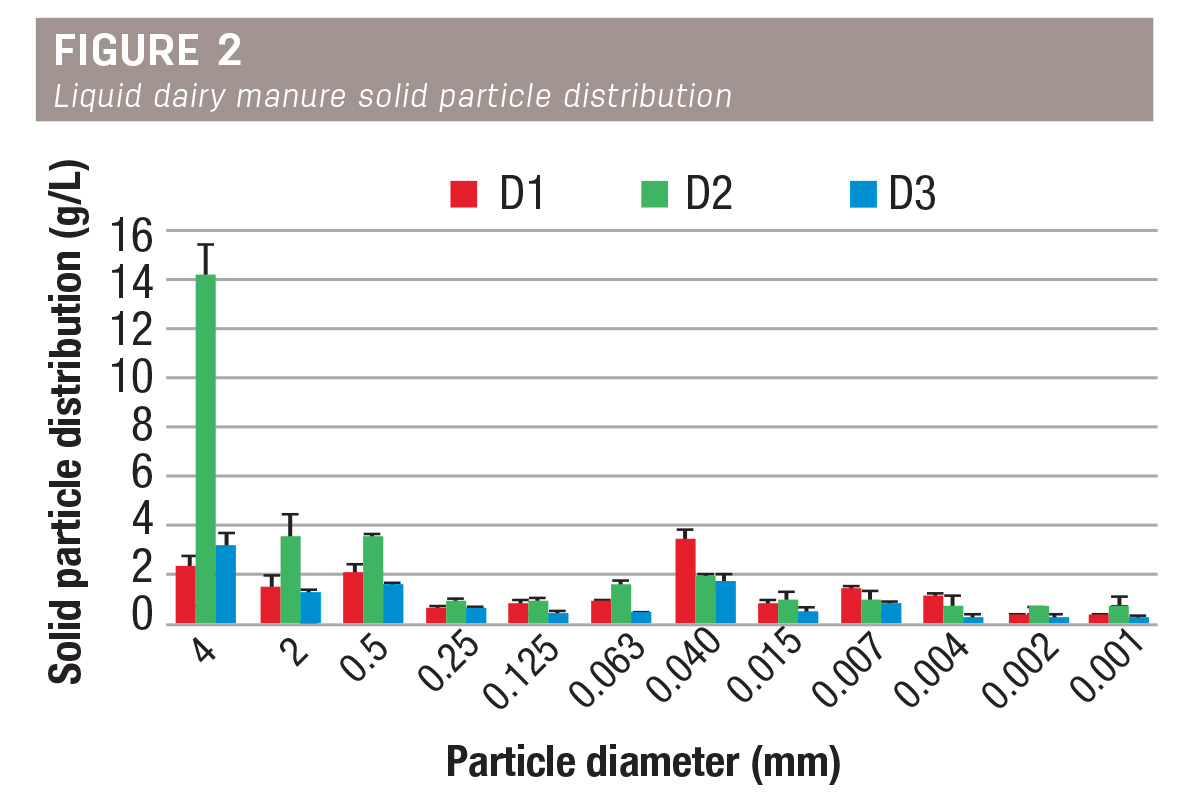

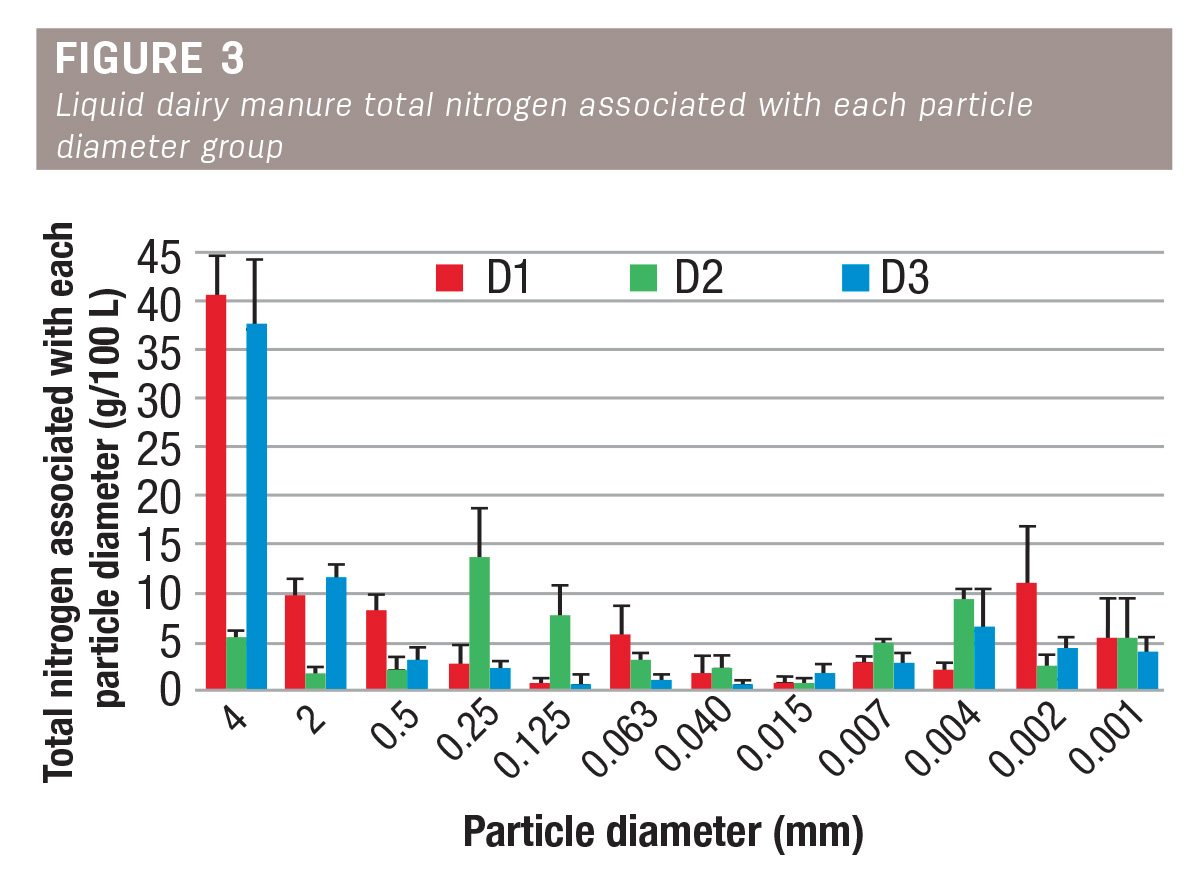

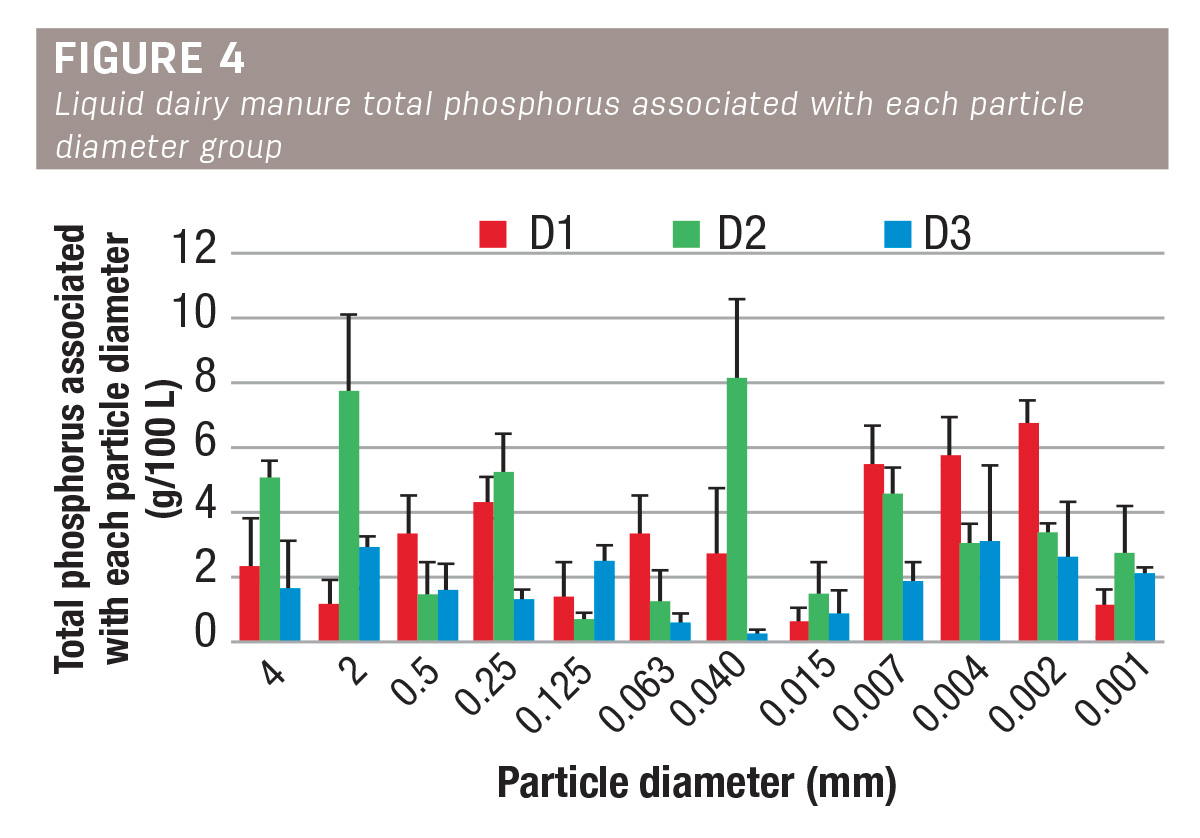

To better address the solids and nutrients separation issue, a critical question needs to be answered: What are liquid dairy manure solid particle and nutrient distributions? Laboratory tests were conducted to find out the information regarding liquid dairy manure solid particle and nutrient distributions. The results in Figures 1-4 are based on liquid manure collected from three commercial dairies located in southern Idaho.

The liquid dairy manure solid particle densities ranged from 1.32 grams per cubic centimeter for particle sizes larger than 4 millimeters to 2.20 grams per cubic centimeter for particle sizes less than 0.063 millimeter. The particle densities were smaller than the commonly used soil particle density of 2.65 grams per cubic centimeter due to the organic bedding materials (compost or separated undigested fiber from liquid dairy manure).

The percentages of solids (dry weight basis) with particle sizes larger than 0.5 millimeter were less than 50%.

The total nitrogen and total phosphorus associated with particle sizes larger than 0.5 millimeter were less than 35% and 25%, respectively.

Given that most total phosphorus and total nitrogen are attached to fine particles with sizes less than 0.5 millimeter, advanced separation methods beyond inclined screens with mesh sizes larger than 0.5 millimeter are needed to separate more total nitrogen and phosphorus out of liquid manure.

On-farm evaluation of inclined screens and centrifuges

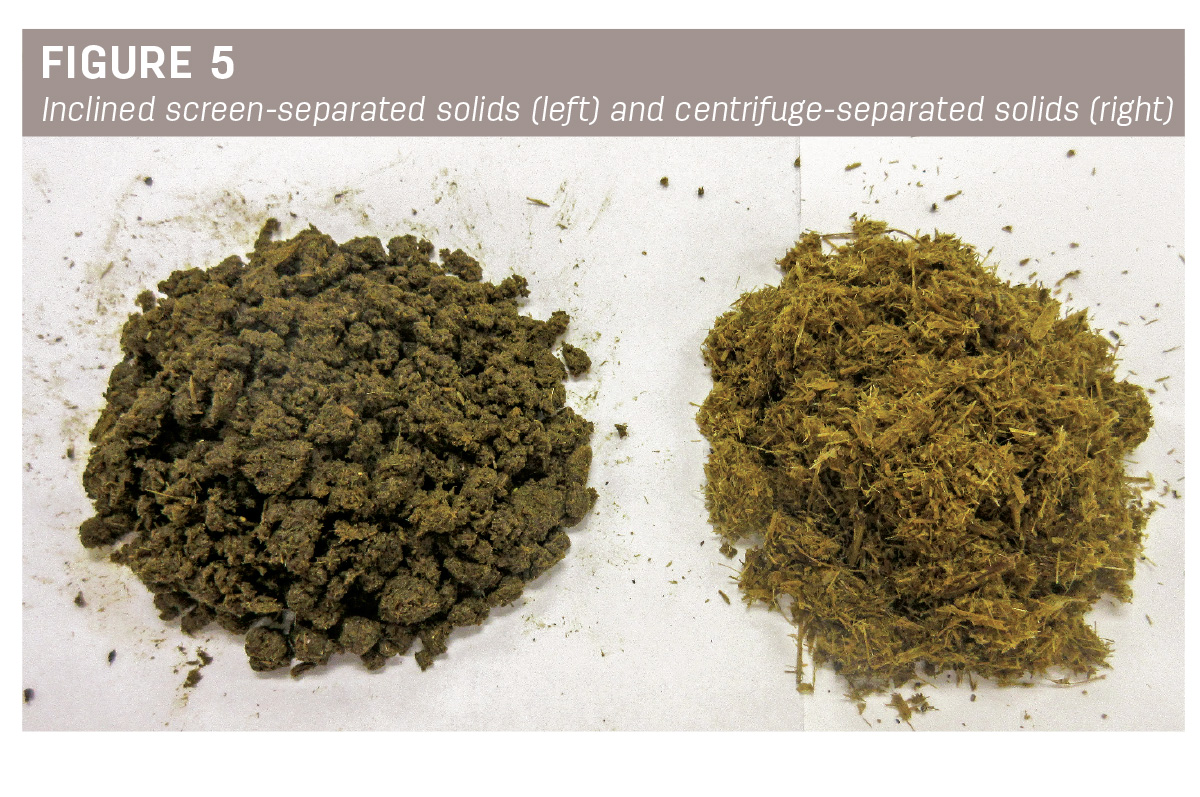

With this new knowledge of solids and nutrient distribution revealed by our laboratory tests, we worked with two dairies on evaluating on-farm performance of both inclined screens and centrifuges for two years. The on-farm test results are shown in Figure 5.

Screens basically separate undigested fibers. Centrifuges separate solids from liquid using centrifugal forces and have a higher separation efficiency for finer particles and associated nutrients compared to screens commonly used on Idaho dairy farms.

A yearlong average of 9.2 pounds per ton and 5.4 pounds per ton of total nitrogen were observed in centrifuge- and inclined screen-separated solids, respectively.

A yearlong average of 8 pounds per ton and 2 pounds per ton of phosphorus as P2O5 were observed in centrifuge- and inclined screen-separated solids, respectively.

A yearlong average of 7.2 pounds per ton and 4.4 pounds per ton of potassium as K2O were observed in centrifuge- and inclined screen-separated solids, respectively.

Regarding the ability of centrifuge to increase solids separation, at a commercial dairy, two parallel inclined screens separated approximately 22 tons of solids per day; on top of that, an extra 24 tons of solids per day were separated by two parallel centrifuges.

Take-home messages

- Liquid dairy manure particle densities ranged from 1.32 grams per cubic centimeter to 2.20 grams per cubic centimeter.

- The percentages of liquid dairy manure solids with particle sizes larger than 0.5 millimeter were less than 50% (21%, 49% and 33% for the three dairies, respectively).

- Most liquid manure phosphorus was associated with fine particles that cannot be screened out by commonly used inclined screens.

- Centrifuges have the capacity to separate fine particles beyond inclined screens that contain higher nitrogen, phosphorus and potassium.

.jpg?t=1687979285&width=640)