Dairy farmers may not consider greenhouse gas (GHG) emissions a key issue, but federal and state governments, the dairy industry, and perhaps more importantly, consumers of dairy products, do. While federal and state GHG reduction targets vary, most have set aggressive goals to cut GHG emissions roughly in half from recent levels by the year 2030. Similarly, the U.S. dairy industry has a Net Zero Initiative with the goal of reaching GHG neutrality by 2050. Consumers are also looking for milk with a lower carbon footprint and dairy processors and food industries are responding to those demands. Furthermore, climate change in the Northeast is increasing the annual average temperatures and the number of hot days that can cause heat stress in cattle. Substantially more precipitation is also occurring, including a 55 percent increase in the heaviest precipitation events. This will impact field work, regional grain production, and will certainly increase manure storage needs as more bunk leachate and rainwater will be collected.

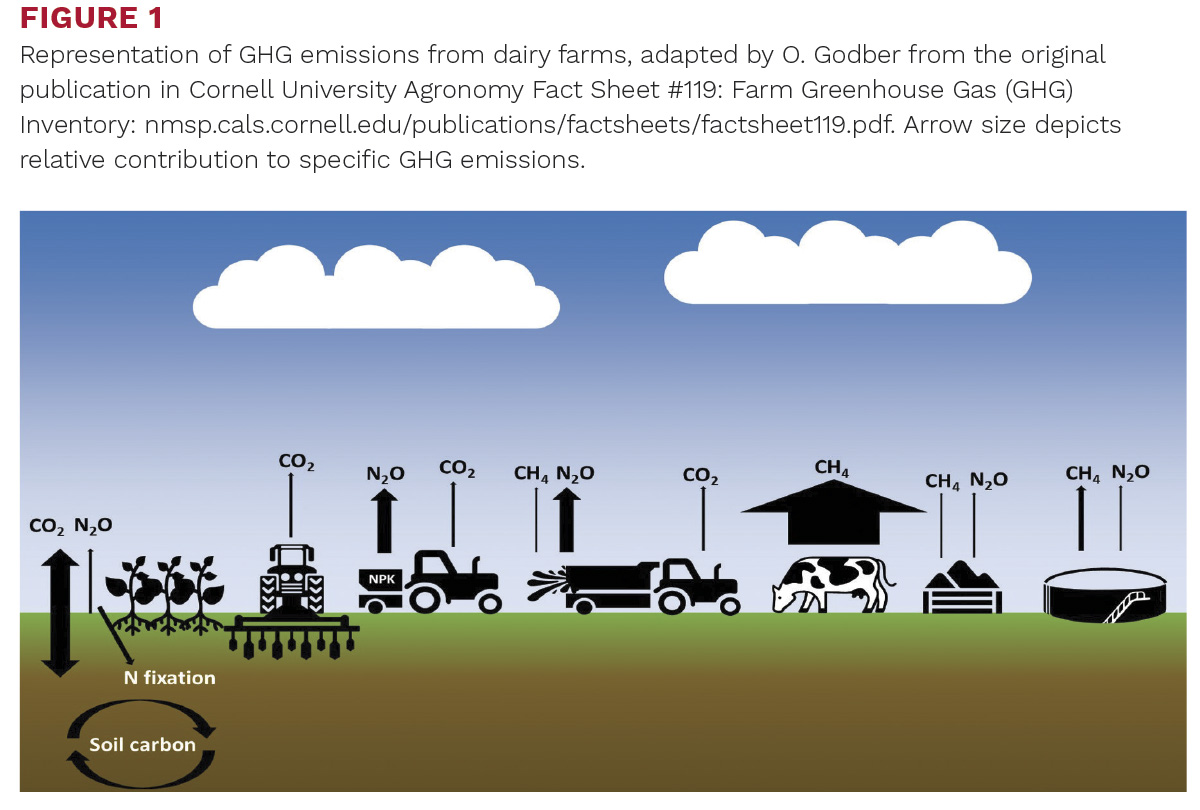

Though dairy production systems may be a relatively small regional contributor to climate change, our farms are uniquely positioned to be an important part of the solution through GHG reduction strategies, opportunities to sequester carbon, and even to generate renewable energy. Livestock production in the Northeast is generally a minor (five to 15 percent) part of a state’s GHG inventory that is typically dominated by other sectors like buildings or transportation. The greenhouse gases of interest to dairy farmers (FIGURE 1) include carbon dioxide (CO2), methane (CH4) that is 84 times as potent at trapping heat as CO2, and nitrous oxide (N2O) that is around 300 times as potent.

Most dairy farm GHG emissions are CH4 from the anaerobic (oxygen-free) conditions of enteric fermentation and long-term manure storage, with N2O emissions emitted to a lesser extent from manure management and agricultural soils. In addition to being the major gas emitted, reducing CH4 emissions is critical as its short lifetime in the atmosphere (less than 12 years) can result in a near immediate reduction in the impacts of warming. While many strategies to reduce GHG emissions are still in development, particularly for enteric CH4, many things can be done today to reduce GHG emissions from manure storages and crop fields.

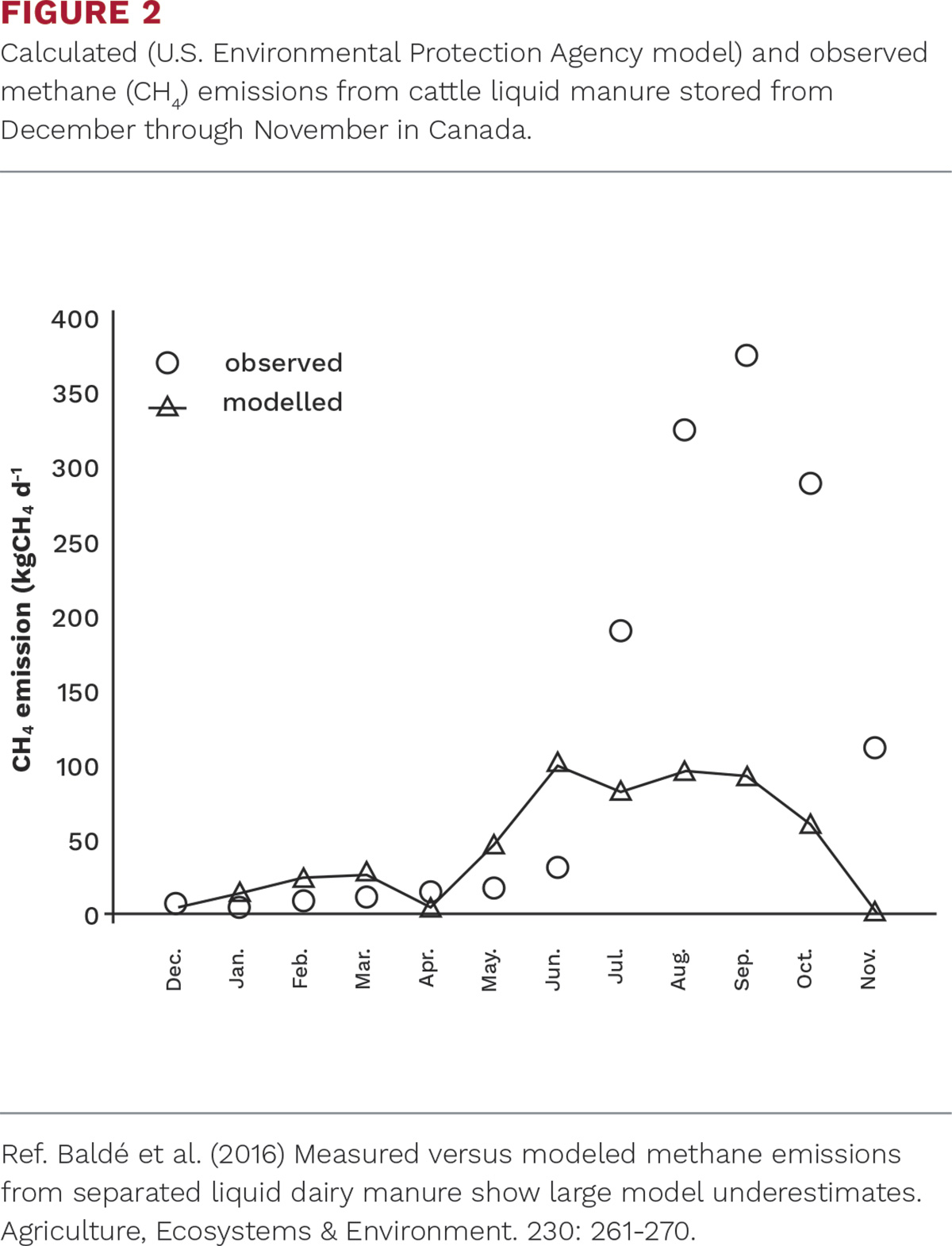

Perhaps the easiest way to reduce GHG emissions is to reduce the amount of manure in storage during summer months. While long-term manure storage is a critical strategy to optimize manure application and nutrient delivery to agricultural soils in a way that protects water quality, anaerobic storage conditions are a leading source of GHG emissions from manure. In cool northern climates, modeled and observational data show the majority of CH4 emissions occur in late summer and early fall (FIGURE 2).

Thus, getting manure spread onto cropland during the growing season and reducing the volume stored in the summer or fall can substantially reduce GHG emissions associated with manure. Many farmers already apply manure following hay harvests, but research suggests potential benefits of side dressing corn and other annual crops with manure, as well as applications to fall cover crops that utilize the nutrients and benefit the soil. In addition to reducing the volume of manure stored, in-season manure applications coupled with proper timing and application methods maximize the nitrogen efficiency of manure and reduce purchased fertilizer inputs, which can have high N2O emissions. Another means to reduce storage volumes in the summer is to get replacement stock out of barns and onto quality pasture during the growing season. In addition to enhancing the industry’s image, this can be a profitable strategy to feed heifers and dry cows.

Solid storage and compost are another means to store less manure anaerobically. Research suggests that stockpiles can reduce GHG emissions by 20 percent and compost by more than 40 percent compared to long-term liquid or slurry storage. It is important to note that management can have a significant effect here as aeration and mixing, particularly in the first few weeks of composting, can release CH4 and lead to the generation of N2O, a potent GHG.

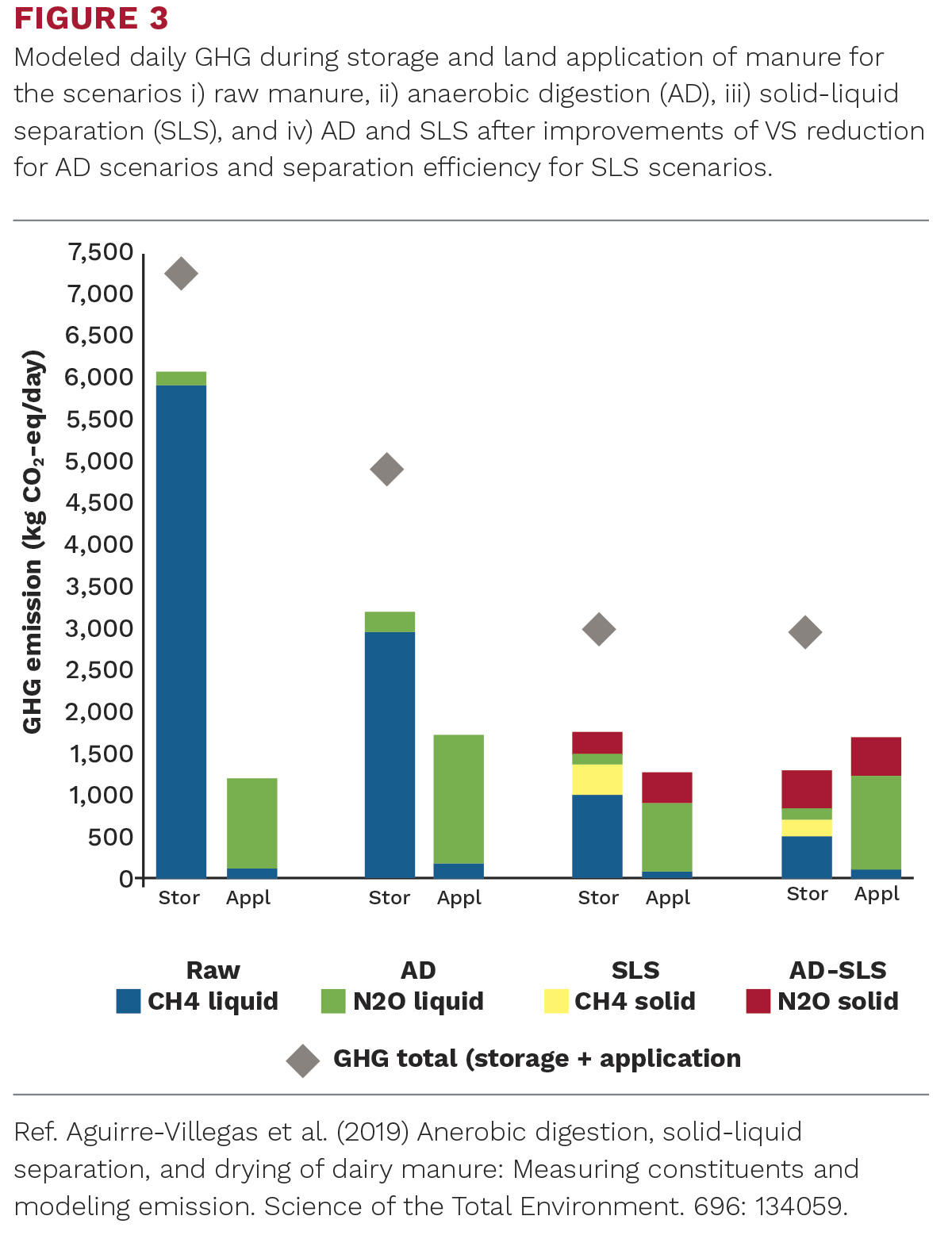

One of the most promising means to reduce manure storage GHG may be solid-liquid separation (FIGURE 3).

High efficiency screw presses that are well-suited for use in the Northeast may reduce GHG emissions by more than 60 percent. Additionally, well-managed solid-liquid separation (SLS) generates dry manure fibers that are suitable for cattle bedding. The savings associated with producing bedding, estimated at $0.65 per cubic foot per lactating cow per day, may also justify the cost of a screw press SLS system. While we recognize the hesitation by some farmers to use separated manure solids as cattle bedding, many farmers across the region are having success with low somatic cell counts and high-quality cow comfort and health.

Solid-liquid separation also positions a farm to install an impermeable manure storage cover. Covers enable the capture of CH4 emissions and their combustion with a flare to the less potent CO2. Cover and flare systems thus offer a near complete elimination of CH4 emissions depending on flare efficiency and the maintenance of leak free covers. These systems are expensive, around $3.00 to $4.50 per square foot for the cover and $70,000 to $300,000 for a flare, depending on its sophistication. There are also concerns about manure agitation under the cover, which is why SLS is critical. Despite the significant investment, covers provide important additional benefits, including nitrogen retention via reduced ammonia emissions, rainwater exclusion reducing manure volumes that need to be transported, and odor mitigation.

Anaerobic digestion (AD) is an even more capital-intensive manure treatment option, promoting a rapid conversion of manure volatile solids to CH4 that is captured. The steady methane production from AD enables it to be used as energy, including for electricity generation, heating, and upgrading to vehicle or pipeline quality gas. When this energy displaces the use of fossil fuels, additional GHG reductions are achieved. However, the storage of warm digestate may be a significant source of CH4. Research has found that that AD paired with SLS can further reduce GHG emissions (FIGURE 3) and covering the effluent storage captures remaining CH4.

If reducing storage volumes, or higher capital investments (SLS, AD, cover and flare) are not suitable for your farm, promoting crust formation on your storage can help reduce CH4 emissions. There is likely a balance though, as high total solids content (more than five percent) has been associated with substantially higher CH4 generation, and very thick crusts that can also generate N2O. On the contrary, manure low in total solids may not develop a thick enough crust and may require the addition of shredded straw to the surface. Crusts also will require additional agitation prior to manure storage emptying.

GHG best management practices for manure

- Reduce manure storage volumes in summer/early fall

- Maximize nitrogen retention of applied manure

- Use solid manure storage or composting

- Solid liquid separation (SLS)

- Cover manure storages after SLS and flare methane

- Anaerobic digestion

- Maintain a “thick crust” on manure storages

|

This article appeared in PRO-DAIRY's The Manager in March 2023. To learn more about Cornell CALS PRO-DAIRY, visit PRO-DAIRY. |