It’s natural and understandable that most of us are instinctively risk-averse. Our challenge sometimes may be to accurately determine our risk versus reward. When lacking facts or experience, we’re unsure and tend to be more cautious, yet by doing so we may unknowingly overinflate our risk or undervalue our reward.

So how best to make an investment decision for our dairy business when we haven’t done so before, or to this extent? How do we do an accurate evaluation when the benefits of the concept being considered are not fully realized?

It is wise to be cautious with any new investment. Becoming knowledgeable on the topic and seeking proof of what is presented is time well spent. Doing nothing is a decision too, and it may be the best one if there are too many unknowns, too little experience or just opinions on ideas that are not validated. On the other hand, being overly cautious and choosing to do nothing in spite of proven benefits yields us no change – and therefore, no benefits.

Cost is an important concern that needs to be discussed in depth. This conversation must also include what you get in return for your money, or the return on investment (ROI). What something costs is one thing, and what that cost brings us (more income/other benefits) is quite another.

It’s interesting: How we look at things changes over time. My grandfather bought his first tractor in the 1930s for about $300. Some farmers said then that $300 was a lot of money and because of this, “Tractors would never replace horses.”

The “never” way of thinking about tractors vanished by the late 1940s, as a vast majority of farms switched from horses to tractors. Farmers quickly came to see, understand and appreciate the incredible ROI (and other benefits) of tractors compared to horses.

I believe this same situation is happening today in regard to the adoption of milking robots, although at not quite the same rate. It may be a question of not if, but when (under what conditions) robots might be right for your operation. One consistent fact is: The ROI for robots continues to increase as labor costs rise and numerous other robotic system benefits not obtainable in conventional systems are identified.

Having been involved with robotic milking since 2007, I’ve been told by some that robots are too expensive based on hearsay. If the information was not fully explained or defined, it is impossible to draw an accurate conclusion. For example, the costs might include the entire project, which contains items unrelated to the milking robots, such as new barn construction, infrastructure upgrades, feed or manure storage/handling, etc. These costs typically exist with any milking system upgrade, no matter if it is robots or a conventional parlor. This is like including the cost of the new tractor with a new high-tech corn planter because they were purchased together and work together. Obviously, the planter cost was less than the total.

The ROI for robotics varies by dairy and as compared to acceptable results or deficits realized today without robots. Factors include herd size, frequency of milking, production levels, milk quality, herd health, repro rates and labor, including costs, regulations, availability, reliability, quality, sustainability, etc.

To determine an ROI for robotics, I suggest an informed discussion as to how this investment would meet or exceed the specific goals and challenges for the dairy, now and in the future. Consider what results you are getting now, what this costs and the sustainability of your current situation. At what cost is human labor no longer viable, or what if quality workers are not available? How might the addition of robotics improve your situation?

There is a particular ROI realized when implementing robotics on dairies currently milking 2X. Many dairies that milked 3X conventionally before robotics also realize a good ROI, but that is a different conversation for a future article. The focus here is that the payback for 2X dairies adopting robots is often greater or faster.

I’ve been involved with numerous dairies milking 2X that switched to robotics and realized a milk yield increase of 15% or more, due to an increased milking frequency and specific feeding per cow. This difference almost always pays for the equipment or more. If you have paid labor, the profit/savings is even greater.

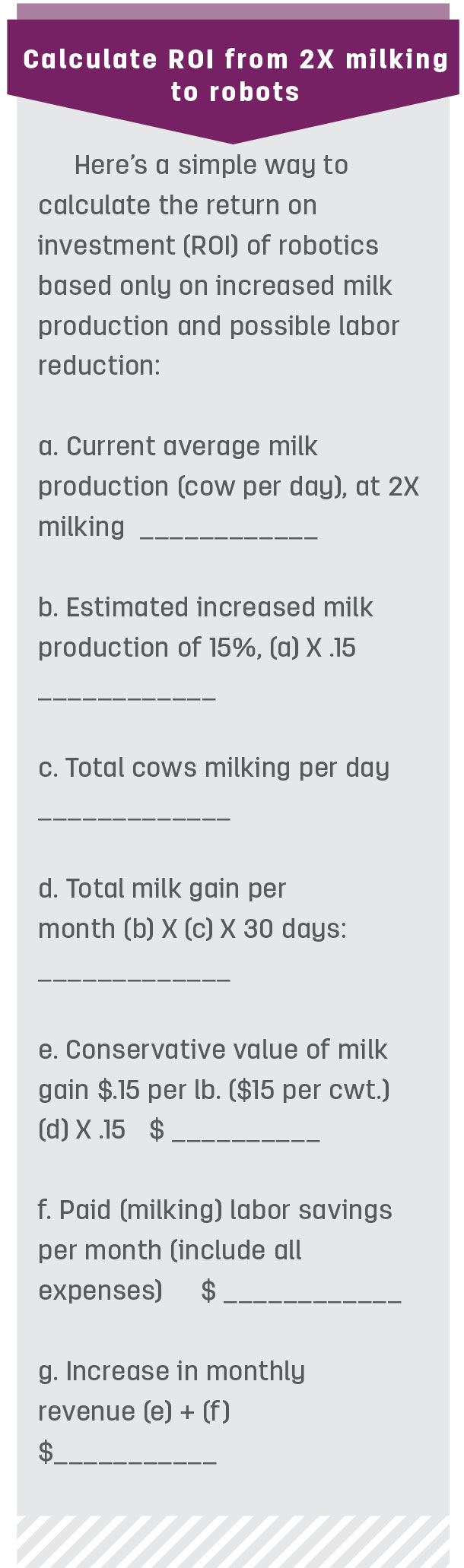

Estimate the potential ROI for your farm using the calculations provided with this article (see below). The amount on the final line (g) is available for robotic equipment investment. In my experience, this amount typically is close to or well exceeds a seven-year equipment payment. Other realistic financial benefits of robots and maintenance costs should also be included with further discussion.

While robots are not for every dairy manager or operation, they can provide a way for some dairies to remain in the industry by allowing for a more efficient and productive operation. The ROI for robotics easily competes with or exceeds that of a milking parlor while delivering greater benefits with much lower risk (easy relocation, great resale potential).

Many robot dairies will verify their investment in robotics created added profitability and/or survivability in financially challenging times. A big bonus that’s realized is when the robots are paid off (at one-third to half the life of the equipment).

With robotics, there is flexibility in building placement that allows us to adapt to different facilities and situations. It is not necessary to build a new barn to add robots, and so far we’ve done more retrofit projects than new barns, including robots placed in suitable tiestall barns.

If you think you’ll never add robots, you may have very good reasons, and that’s one decision that can be made. If you want to explore your options and feasibility, we are fortunate to have good information and data available from numerous dairies willing to share their experience. Seek this input from a good number of varied and experienced operators to see what they’ve accomplished. Considering options for your future has no downside and no cost.

Like me, you or someone you know probably not long ago said they’d never have a cellphone or use a computer – but now do. It’s interesting how our appreciation for newer concepts changes once we clearly realize the advantages and the ROI.