Milk at $14 per hundredweight brings the reality of your future in the dairy business to the forefront in a SWOT (strengths, weaknesses, opportunities, threats) evaluation of your farm. Investing millions of dollars hoping the milk price will get better is not a rational strategy.

However, there exists, as in all challenging times, opportunities to capitalize on distressed assets and market turmoil. If you have a solid milk market or hold a contract for your product, you can utilize a modular expansion strategy to maximize your future productivity.

Traditionally, expansions meant major capital expenditure, adding a substantial number of cows in one transaction and building housing or corrals to facilitate the expansion. This required new permits, additional debt, labor management resources and fortunate timing to ensure success.

With tightening milk markets and stricter environmental regulations, these larger expansions create challenges with neighbors, even in sparse rural areas. “Not in my back yard” was the message from the local communities.

As the industry changes, it is time to look at things differently, to spread risk and ensure business decisions are sustainable and durable.

The size of a future expansion can be affected by many different considerations. Establish your why to determine the best choice for your farm. Some possible expansion scenarios are below:

- Too many heifers internally, with little market to sell. A smaller expansion could suffice and robots could be the solution.

- Acquisition of a larger neighboring farm. A larger expansion would suffice; consider a rotary or robots.

- Consolidation of a second site or farm to achieve greater scale and efficiency with limited capital may best be solved with a traditional parlor or rotary.

A high percentage of people looking to update facilities bring up labor as the key challenge they face. We have a tight labor supply with costs escalating and people that are hard to find. This will only get worse as the overall economy improves and people have other opportunities off the farm.

We must create an environment where the working conditions, wages and quality of life allow us to attract labor back to agriculture. This will take creative managers that use technology to solve and reverse these issues in the future. That alone has initiated the discussions about robots over the last several years.

The scalability of layout, design and management systems has driven the move toward robotic milking for herds approaching 10,000 cows. Farms that three years ago saw rotaries as the only solution are now considering and purchasing robots.

With 90 percent of labor needs being dayshift labor, robots are seen as a management tool to attract a higher-quality career-minded employee. Robots have also been known to create an environment that women and men can compete in equally with the same compensation and opportunity for advancement.

The challenge is balancing higher capital requirements and increased labor efficiency versus lower capital requirements and higher labor costs. Robotic solutions are gaining in market share and performance. The evolution of doing things differently to achieve better results is happening across the globe. Conventional wisdom has been a war of attrition over the past 75 years. The cost to produce 100 pounds of milk is equal with rotaries or robots with proper design and layout.

Let’s look at two scenarios to see how the advantages and challenges on your farm affect the choices moving forward.

Example: 3,500-cow farm milking in a double-50 parallel, expanding to 5,000 cows

You have a sound current milking facility that is working well. You are looking at a new, larger parlor or an additional robotic milking facility to add additional cows.

Options:

1. Add 20 to 24 robots to milk the extra 1,500 cows using the same feed center and connecting it to the existing waste management system. Add the cows with minimum labor and utilize the current infrastructure to maximize efficiency of the dairy. Utilize the existing parlor to milk the current 3,500 cows.

2. Build a 100-stall rotary and milk 5,000 cows 3X and close the current parlor. Utilize automatic pre- and post-spray robots and employ three people to milk 700-plus cows per hour. Utilize the existing housing and add more for the 1,500-cow expansion.

Example: 1,200-cow expansion on green field site

Options:

1. 16-robot barn. Labor at 300-plus cows per FTE (full-time employee) with proper design and management.

2. Double-20 parlor. Labor at 150 cows per FTE. Lower capital cost, higher labor costs. Expandable, with room for future growth.

A good rule of thumb

I tend to use the following rule of thumb when asked what is the better solution.

- 100 to 3,000 cows = robots. The advantage to cow performance and longevity, as well as work environment for employees and owners, will offer long-term sustainability.

- 3,000 or more cows, long-term horizon = robots. Labor costs and availability will continue to be a challenge.

- 3,000 or more cows, short-term horizon = rotary. The succession plans may not be clear, and the cash flow of higher capacity milking more cows with the current oversupply of heifers makes sense to a lot of operators.

Summary

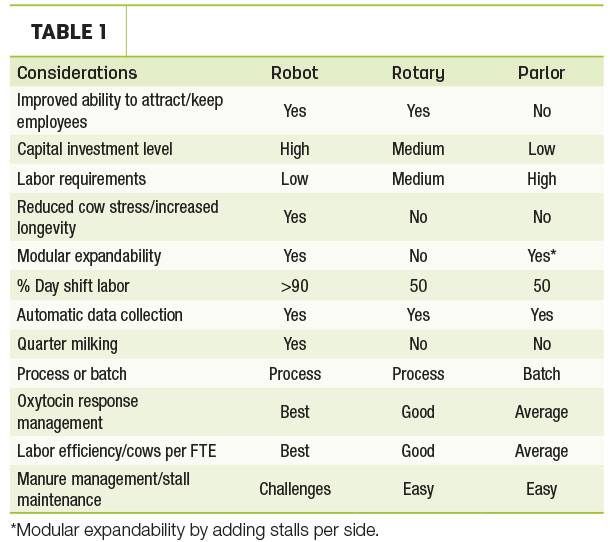

Table 1 shows the differences we are seeing with robots compared to other milking options.

For instance, the management of the oxytocin response is more effective in robots and rotary parlors, and labor is easier to manage with the herd management monitoring systems on both. Process versus batch milking has key benefits to cow performance. Labor continues to drive the economic choices of capital cost versus labor requirements.

Doing a thorough SWOT analysis on your farm is a critical place to start in your decision of how to chart your future. Thoughtful review of circumstances and alignment with your long-term goals can give you the best opportunity for success. Stick to your vision for your business and learn from the exercise.

The marketing of milk is the key factor these days. If you have a solid milk market (secure contract), with the lower price of cattle today, this is the best entry point into the dairy business in 40 years. There are significant opportunities for the younger generation to gain entry into the business as the older generation transitions out of the business. Someone needs to produce 200 billion pounds of milk each year to feed a hungry planet. ![]()

PHOTO: Using technological advancements is one way to attract labor back to agriculture. Photo courtesy of DeLaval.

-

Kirt Sloan

- Western U.S. VMS Sales Specialist

- DeLaval

- Email Kirt Sloan