In Canada and around the world, dairy production researchers are a prolific source of new knowledge, necessary for the progress and profitability of the sector. Government and industry invests millions of dollars in research and expects to be able to measure an impact at the farm level.

That’s the challenge: There’s a long way between the publication of a scientific article and the adoption of a new practice on the farm.

How can this new knowledge be integrated in the habits of dairy farmers? In what form and context will it be useful? How can it be profitable?

Finding answers to these questions (and many more) is the purpose of what we call “knowledge transfer” or what is increasingly known as “knowledge mobilization.”

During the CDN Dairy Cattle Improvement Industry Forum 2018, I shared three different success stories of dairy research knowledge transformed into on-farm action. Here are each of those stories.

Julie Gagnon and the training course: ‘The Barn, a Source of Comfort’

“I want to know all about what will make me get this little 10 to 15 percent of additional profits.” - Julie Gagnon, Ferme Ciboulette, Quebec

Julie Gagnon is always eager to learn and claims to not have missed a single training session in her region since she left school. She particularly appreciates the more detailed one-day classroom training course formats. “I want to be challenged,” she says.

Like the 1,664 producers and interveners from Quebec and the Maritime provinces, Gagnon participated in “The Barn, a Source of Comfort,” a training course offered by Valacta to explore practical ideas to improve barn comfort.

In addition to the knowledge from the latest Canadian Dairy Research Cluster on cow welfare assessment and comfort factors in cow housing, Gagnon says she particularly appreciated the constructive exchanges between participating producers.

“I brought something to others, and they brought something to me,” she explains. She also liked the videos presented “because they show concrete examples of producers who have done the real tests.” (For those interested, the videos are available on Valacta’s YouTube channel.)

With the knowledge acquired in training and the support of her team of stakeholders, including her dairy production adviser, Lorianne Pettigrew, Gagnon had everything in hand to make the necessary modifications to improve the comfort in her barn.

Over the year, her herd’s production increased by about 200 kilograms of milk per cow for Holsteins and 100 kilograms for Jerseys, and the next few months will determine if the trend continues.

Conversely, the cull rate fell significantly, from 33 percent to 21 percent in one year, due to better cow condition. For Gagnon, this improvement represents about $10,000 more per year or a savings of $1.60 per hectolitre delivered.

Brian Smit and the farm workshop: ‘Ready, Set, Grow’

"My money is well spent when I come back at the farm with an idea ready to apply." - Brian Smit, Bethesda Holsteins Ltd. Nova Scotia

For Brian Smit, classrooms don’t necessarily have four walls, tables and chairs. He does like to read and attend conferences but often feels too much time is wasted presenting unnecessary details.

He prefers to learn in a real setting, directly on the farm with concrete ideas ready to be applied. He particularly appreciated the half-day workshop in a neighbour’s barn titled “Ready, Set, Grow.”

In addition to the demonstrations and recommendations given by trainer Dorrance Stirling from Valacta, it was the look of his neighbour’s calves that particularly impressed Smit during the workshop.

“I’ve been raising my calves the same way for 10 years, and I thought I was doing a decent job, but I realized there was room for improvement,” Smit says.

Motivated to do otherwise, and inspired by the workshop content, he quickly made changes to his calf feeding practices.

Not everything worked the first time but, after a few tests and adjustments, the efforts paid off. Within a year, the average age at first service had decreased by three months.

It can be said Brian succeeded in turning dairy knowledge into profitable action in his herd, especially since cows that calve younger at the right weight are known to be more productive and profitable.

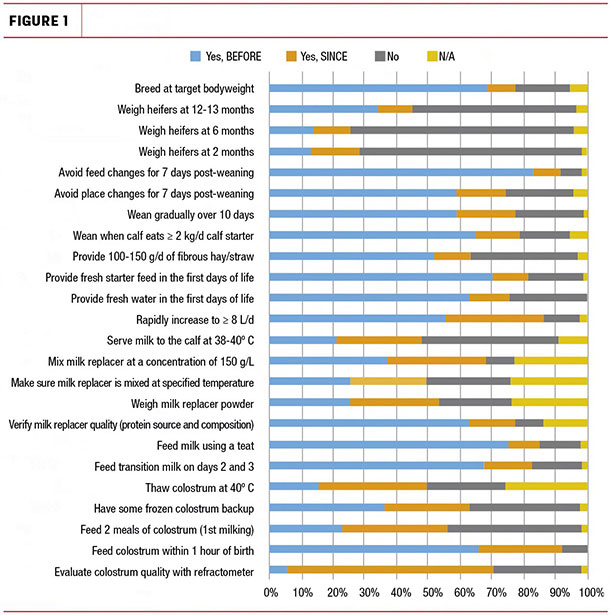

And he is not the only one, since 1,475 dairy producers from Quebec and the Atlantic provinces adopted the various recommended practices during the workshop, as illustrated in Figure 1.

Jonathan Houle and the online project: ‘Robotlab’

"I'm not a big reader, and I didn't have time for training courses in the past years." - Jonathan Houle, Ferme Denart, Quebec

A young dairy farmer in Abitibi, Quebec, and father of two children, Jonathan Houle wants to spend more time with his family. That’s why he decided to make the transition to robotic milking.

Such a project involves major changes in herd management practices and requires adequate preparation for a successful start.

Different options were explored to meet this need of information about robotic milking. Given that producers switching to robots are scattered in different regions, and not all at the same stage of their project, a traditional face-to-face course format would have been difficult.

This is how the Robotlab online training project was born. Seventeen producers from different regions in Quebec participated, including Houle.

Over a period of a few weeks, participants attended webinar sessions and benefited from written and video content, audio podcasts and the input of their peers and the robotic milking experts involved.

For Houle, it was a very positive experience: “The internet format is great. You can attend everything without having to travel. I could not have done it otherwise.

Access to online documents and webinar recordings allows us to take over the material if we are unable to do so. And being able to ask questions to experts almost any time is a big plus.”

Houle’s robotic start-up has yet to come, but the knowledge and tools he acquired during his training experience has already allowed him to adjust his planning and the herd’s preparation.

Considering the high costs of a transition to robotic milking, the importance of turning relevant and up-to-date knowledge makes even more sense.

Tips for trainers: Just for me, just enough, just on time

Among the many routine daily tasks, visits from representatives and stakeholders, fieldwork, paperwork, etc., how much time, interest or energy do producers have left to learn about new research results? Not to mention the needs are different between farms and individuals.

Plus, there are so many learning opportunities … How can one grasp everything? Some will prefer reading, for example, while others learn better in action.

That’s why it’s important to follow the golden rule of the three J’s: Just for me, just enough, just in time. In other words, identify producers’ needs while using a variety of means to reach them and then prioritizing and adapting messages according to utility.

In addition, it is important to gather as many conditions as possible associated with successful knowledge transfer:

- The winning conditions should consider three aspects: the individual, the environment and the approach used. For example, a concerted and consistent message among stakeholders will have more impact.

- The more motivated producers are, and the more they perceive the usefulness of a new practice, the more they will adopt it.

- The use of different learning methods and over a continuous period of time will increase the success of knowledge transfer.