The term “high-moisture corn” (HMC) can technically be applied to any corn harvested above traditional combining moistures and then allowed to ferment in a storage structure. HMC can range from 22 to 24 percent kernel moisture – recommended for sealed, upright storage structures – to 30 to 36 percent kernel moisture for bunker-stored snaplage.

HMC can be harvested with a combine as high-moisture shelled corn. Earlage is harvested with a corn picker or combine while retaining some of the cob. Snaplage involves using a forage chopper retrofitted with a snapper corn head to harvest the ear and husk.

Growers are becoming more interested in snaplage, as they see major cost savings over harvesting corn with a combine and having to process kernels at their storage structure. Recent studies have also confirmed snaplage, if harvested at the proper kernel moisture, can have extremely high feeding value when processed and stored correctly.

To capture the most starch per acre, HMC harvest should not begin until the kernels have reached black layer and are physiologically mature. For most hybrids, kernels will be between 34 to 36 percent moisture at black layer.

Always be sure to reference kernel moisture when making earlage or snaplage harvest recommendations. Most growers own a kernel moisture tester, and the final product may have varying amounts of cob or husks, which can impact moisture levels.

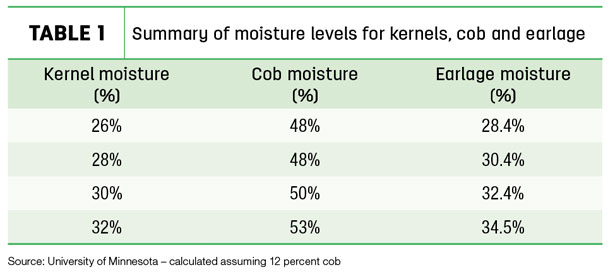

Also, remember the cob carries more moisture than the kernel. A traditional rule of thumb is: The final earlage or snaplage mix will be about 3 to 4 percent wetter than the kernel. This is based on ears in modern corn hybrids being about 10 percent cob.

Targeting kernel moisture levels of 28 percent or greater generally results in a product that seems to work best in terms of storage, fermentation and ruminal starch digestibility.

Table 1 summarizes moisture levels for kernels, cob and earlage. Earlage and snaplage energy values can vary from one operation to another due to differences in the amount of cob and husks contained in the feed.

Wetter, greener hybrids usually do not harvest quite as cleanly and tend to have higher husk content, which can dilute starch and reduce energy content.

Snaplage

At first glance, snaplage is not a particularly attractive product due to the presence of “stringy” husks. Getting husks in snaplage chopped as finely as in corn silage is far more difficult, as only ears are fed into the chopper. In addition, there is space between the ears, and they are not held tightly against a crop mat or shear bar. There is also no way to control the direction in which ears enter the cutter head.

Obtaining desired chop length is easier with corn silage due to the thicker crop mat and because nearly all ears enter the feed rolls with the stalk perpendicular to the shear bar.

There are several ways the forage chopper can be modified to reduce husk particle size:

- Set the chopping length as short as possible to slow the feed rolls down.

- Use different drum bottoms with a key stock welded every 2 inches perpendicular to the knives (depending on the manufacturer) to help cut the feed going through the chopper.

- Add a re-cutter screen behind the knife drum before it enters the processor. This will slow down the crop flow, however.

Pioneer conducted a snaplage field study to evaluate the yield and nutritional content of four hybrids harvested at four different maturities. The study found cob digestibility declined by nearly 20 percent over the four-week harvest window. Husk and shank also declined somewhat with increasing ear maturity but remained relatively high across all harvest periods.

Maintaining cob digestibility is yet another reason for targeting earlage or snaplage harvest at kernel moistures exceeding 28 percent or very soon after kernels reach black layer.

Kernel damage and digestibility

Nutritionists have learned to pay close attention to the particle size of kernels in corn silage or in dry, ground corn. The same attention needs to be paid to particle size of HMC.

Typical kernel particle size goals with HMC are 800 to 1,200 microns, with a small standard deviation desirable to prevent excessive fines or large particles. It is equally important grain particle size be monitored in earlage and snaplage to ensure optimal packing qualities and fermentation.

To maximize kernel shearing and damage with snaplage, set the chop length as short as possible and ensure the chopper processor has relatively fine-toothed rolls (e.g., five to seven teeth per inch) with a 1- to 2-millimetre gap setting and a 30 to 40 percent differential (typically greater differential than for corn silage).

The ruminal starch digestibility in HMC at greater than 28 percent kernel moisture will increase over time in fermented storage due to the breakdown of the zein proteins that surround and cover kernel starch granules.

Zein protein is not digestible and acts as a barrier to rumen microbes accessing starch granules for digestion. When the zein covering is broken down in fermented storage, the kernel’s protein component and starch become highly available for digestion by rumen microbes. This is especially important to consider if transitioning cows from drier HMC to a product with higher kernel moisture.

Typically, about 70 percent of the starch will be ruminally degraded in wetter HMC, and this will increase by approximately 2 percent units per month and stabilize after about 12 months of storage.

HMC ensiled at less than 24 percent moisture will typically not increase in starch digestibility due to the ensiling process, which doesn’t allow lactic acid bacteria to grow at lower moistures.

Producers and nutritionists alike will have their preference on the type of corn being added to their rations. Depending on the situation, dry corn might be a better fit over HMC or vice versa. However, this can change, as the HMC’s rumen digestibility and the whole-plant corn silage starch will increase over time. ![]()

-

Martina Pfister

- Ontario Dairy Specialist

- Corteva Agriscience, Agriculture Division of DowDuPont

Pros and cons of high-moisture corn

Here is a quick overview of high-moisture corn, which may help you choose the option that works best for your needs:

Advantages

- Earlier harvest that fits well between corn silage and dry grain

- Increased yields of 9 to 12 percent per acre if also harvesting the cob

- Potential cost savings compared to harvesting dry corn and processing at the storage structure

- Higher ruminal starch availability compared to dry corn

- Additional source of digestible fibre if cobs and husk are harvested in a timely manner

Disadvantages

- Fermentation and feedout losses

- Potential for the corn crop to get overly dry, reducing digestibility and palatability

- Higher inventory carrying cost

- More inconsistent than dry grain because of changing starch digestibility over time in storage. If the corn crop gets too dry (e.g., kernel moistures less than 25 percent), problems start to mount in terms of reduced cob digestibility in earlage and snaplage, fermentation issues and potential instability in the feedbunk.