Farm tours Wednesday, Jan. 27

Six farms will open for tours. Producers are welcome to stop by during the times listed for each farm and are asked to wear the biosecurity boots provided at each location. Lunch will be available from 11 a.m. to 2 p.m. at Dale Jerseys and Grace-Mar Farms. Owners, building contractors and equipment suppliers will be on hand to answer questions.

Bileena Holsteins

Bileena Holsteins

Bill and Henny Klop and Alex and Amanda Klop

Agassiz

10 a.m. to 4 p.m.

Bileena Holsteins is milking 95 cows with a double-box robotic milking system. They were able to retrofit their existing barn by adding 28 feet of length and not having to move or disrupt their milking here.

The robotic milking equipment incorporates 3D time features that include flight camera, in-liner teat preparation and stimulation that ensures clean and dry teats, one-step attachment, conductivity monitoring and discarding of milk by individual quarter, standard dual milk filtration system, easy-to-use robot data manager system and sort gates.

The farm uses a herd health and activity monitoring system. It also installed a new grain bin and flex auger.

Crossroads Dairy Farm

Crossroads Dairy Farm

The Arends family

Abbotsford

8 a.m. to 12 p.m.

The Arends family installed a new 40-stall internal rotary herringbone parlour at Crossroads Dairy Farm in Abbotsford. It is equipped with free-flow meters with blood and conductivity monitoring as well as automatic dipping and flushing milk claws that post-dip the cows and backflush the machines after each milking.

The overview touch screen in the parlour tracks all cows on the deck and audibly alerts the milker if any irregularities are noticed. The barn’s flush system includes a 30-horsepower flush pump, seven 12-inch airbag valves and a pneumatic controller.

Dale Jerseys

Dale Jerseys

Robert and Karen Dale and sons Christopher and Brian

Mission

9 a.m. to 4 p.m.

A new drive-through barn at Dale Jerseys has two robotic milking systems which feature on-board somatic cell counters and a chemical back-flush system.

The barn showcases automated grain feeding, anti-slip floor protection in high-traffic areas, flexible feed fence, protected feed surfaces, comfort stalls, traction rubber on feed alley and crossovers, curtains, cyclone fans and alley scrapers.

Grace-Mar Farms

Grace-Mar Farms

Wally, Mike and Richard Tenbrinke, John Kampman

Chilliwack

9 a.m. to 4 p.m.

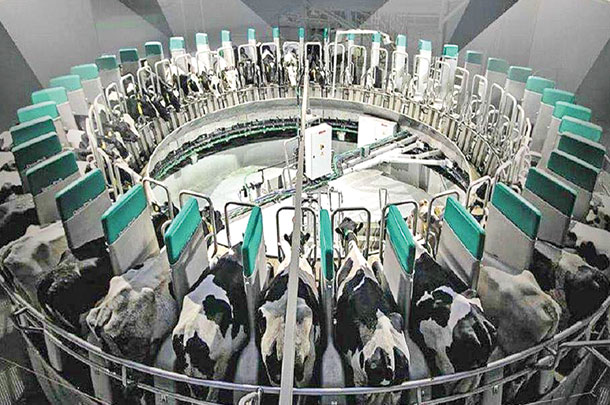

Grace-Mar Farms is constructing a first-of-its-kind-in-North-America, 60-stall robotic rotary milking parlour.

Each stall unit has its own robotic module for full automation of teat cup attachment, teat preparation (including pre-dipping, forestripping, stimulation), milking, conductivity monitoring and post-dipping, all done within the teat cup liner in one single attachment; backflushing occurs after automatic removal.

The farm manages manure with a flush system complete with separation.

West River Farm

West River Farm

Gene and Sarah Sache, Grant and Shawna Sache and families

Rosedale

10 a.m. to 4 p.m.

The new, six-row, sand-bedded barn at West River Farm holds 130 milk cows and 40 dry cows. A sand lane is used to recycle sand bedding.

There are three robotic milking machines equipped with milk quality control/somatic cell counting system testers for each quarter and weighing floors. Movement and rumination activities for milking herd and heifers are managed with long-distance monitoring equipment every two hours for optimization of heat detection and breeding times.

The barn has cow brushes for comfort, an automatic feed pusher and manure scrapers. It is expandable for a fourth robot and 240 milking cows.

Whatcom Acres Farm

Whatcom Acres Farm

The Gietema family

Abbotsford

10 a.m. to 3 p.m.

At Whatcom Acres Farm, the 300 cows (milking and dry) are fed in two separate barns by an automatic feeding system. It was installed in June as a retrofit project in the farm’s existing structure. The feeding system prepares different combinations and volumes of rations depending on the makeup of the nine different cow groups.

A block cutter is used for cutting corn and grass silage into blocks for placement in the feed kitchen prior to mixing and distribution. For manure management, the farm recently added a dewatering separator to its existing in-vessel compost system.

The separator allows for fine separation without screen cleaning and for high throughput without the need to manage feed rates even if dissolved manure solids content is high.

Seminar Program

Thursday, Jan. 28

This year’s B.C. Dairy Expo seminar will focus on precision dairy farming technologies. As more and more new technologies are being presented and adopted by dairy farms worldwide to improve production efficiencies, this year’s seminar will address the question of application, economics and selection of precision dairy technologies of greatest potential benefit to the industry.

The first presenter is Jeffrey Bewley (pictured above), University of Kentucky. Bewley grew up working on his grandfather’s dairy farm in Rineyville, Kentucky. He received a bachelor’s degree in animal sciences from the University of Kentucky in 1998.

The first presenter is Jeffrey Bewley (pictured above), University of Kentucky. Bewley grew up working on his grandfather’s dairy farm in Rineyville, Kentucky. He received a bachelor’s degree in animal sciences from the University of Kentucky in 1998.

In 2000, he completed his master’s degree in dairy science at the University of Wisconsin – Madison under the direction of Roger Palmer. His doctorate work under Mike Schutz at Purdue University focused on the application and economics of precision dairy farming technologies.

Bewley’s program focuses on precision dairy technology implementation, mastitis prevention, cow comfort, lameness prevention and decision economics.

The second presenter is Dr. Ronaldo Cerri (pictured above), University of British Columbia. Cerri is from São Paulo, Brazil. In 2001, he received his DVM degree from the College of Veterinary Medicine at São Paulo State University.

The second presenter is Dr. Ronaldo Cerri (pictured above), University of British Columbia. Cerri is from São Paulo, Brazil. In 2001, he received his DVM degree from the College of Veterinary Medicine at São Paulo State University.

Cerri acquired his doctorate in 2008 in the animal biology program from the School of Veterinary Medicine at the University of California – Davis and later worked as a postdoctoral fellow at University of Florida until 2010. He currently holds a position as an assistant professor in animal reproduction at UBC.

Cerri’s research focus is on development of strategies to overcome the sub-fertility in dairy cows, such as the use of automated methods for detection of estrus, ovulation time and health disorders. Moreover, applied and basic function of reproductive tissues related to nutraceuticals and health are key aspects of his research.

Tentative plans also include a short overview of the Trans-Pacific Partnership talks and agreement.

There is a $20 registration fee, which includes entrance to the Pacific Agriculture Show and dairy seminar, lunch following the seminar and copies of any seminar proceedings. Registration begins at 9 a.m. with the seminar starting in the BMO Room at 10 a.m.

For more information on the seminar, contact Tom Droppo, dairy industry specialist, British Columbia Ministry of Agriculture by email or call (604) 556-3144. PD

For more information on the farm tours, contact John Luymes, farm structures engineer, British Columbia Ministry of Agriculture by email or call (604) 556-3114.