Unfortunately, still today, the most common form of manure management practised at farms in Canada often involves “no treatment” at all. For instance, take your typical modern dairy farm: Automatic scrapers push manure from the alleys in a freestall barn into an interim storage pit from which the slurry is subsequently pumped to a storage lagoon and eventually spread back on the farm’s fields.

If left untreated, an anaerobic process becomes established in this stored slurry which can lead to a problem situation: floating layers or solidified sedimentation layers in the slurry tank or lagoon; a need for extensive agitation before applying the slurry; an acrid, pungent smell in the area of barns and pits; gas emissions during stirring and application of the slurry; potential burning and scorching of crops after application; and many other problems.

Often, despite the farmer’s best efforts, the slurry fails to produce the desired fertilizing effect. This leads to the application of additional fertilizers and other crop protection measures.

The underlying problem – putrefaction

Typically, slurry will become a problematic waste product when conversion takes place by means of putrefaction processes. This involves decay under anaerobic conditions, i.e., in the absence of oxygen. Anaerobic conversion of slurry leads to the development of malodourous gases, including hydrogen sulphide and ammonia, and odourless methane gas.

Also problematic, the odour carriers in manure – indole and skatole (3-methylindole) – attract harmful insects. These insects lay their eggs in the slurry, and the subsequent larvae are contained in the slurry, which is applied to the crops, leading to crop damage and the need to apply pesticides.

Furthermore, the valuable substance ammonium nitrogen is lost in the anaerobic slurry because ammonium is converted into ammonia (off gases by volatilization) and is no longer available for plants.

Oxygen through aeration

The conventional method of introducing oxygen into the slurry involves mechanical aeration by means of agitators or compressors. However, this technical method can be difficult when dealing with large quantities of slurry, which cannot be stirred effectively every day.

Floating layers then quickly form, further sealing off the slurry from the oxygen supply and thus strengthening the anaerobic environment. The capital cost and annual energy costs of lagoon agitation can also be considerable.

The natural solution – decomposition

But there is another way. The simple and natural solution to turn slurry into a valuable organic fertilizer involves activating those decomposition processes in the slurry which only take place with oxygen.

The decomposition processes involve mould fungi, yeasts and other micro-organisms and include several biological processes absolutely vital to maintaining a state of equilibrium in nature.

Mould fungi very quickly bind any ammonia present in the first stage of the rotting/decomposition process to form ammonium nitrogen, which is subsequently available to plants as a slow-release source of nitrogen.

The harmful and unpleasant biogases are also largely eliminated, providing for a noticeable difference in the pit/lagoon or storage tank and during application.

A healthy, decomposed slurry thus constitutes an important element of a closed substance cycle management system that benefits the soil, plants, animals and humans alike.

Activating sludge

The best solution is a simple method that activates the aerobic bacteria while avoiding the need for agitation (or external energy) and other factors detrimental to the environment.

There are products that can replicate the specific properties of oxygen and reactivate the life process of the slurry (without requiring aeration). The putrefactive bacteria die and the oxygen, which is present in the slurry, is aerobically activated.

An oxygen-producing and breathing biomass quickly results. The micro-algae that develop change the colour of the slurry to dark green and the work performed by the bacteria renders the slurry homogeneous.

In the course of time, existing floating layers and sedimentation layers dissolve (see Figure 1).

As a natural side effect of these processes, the smell is diminished and a more nutrient-rich valuable organic fertilizer results. Using the decomposed (or rotted) slurry produced in this manner enables the quantity of commercial fertilizer used to be reduced.

As a natural side effect of these processes, the smell is diminished and a more nutrient-rich valuable organic fertilizer results. Using the decomposed (or rotted) slurry produced in this manner enables the quantity of commercial fertilizer used to be reduced.

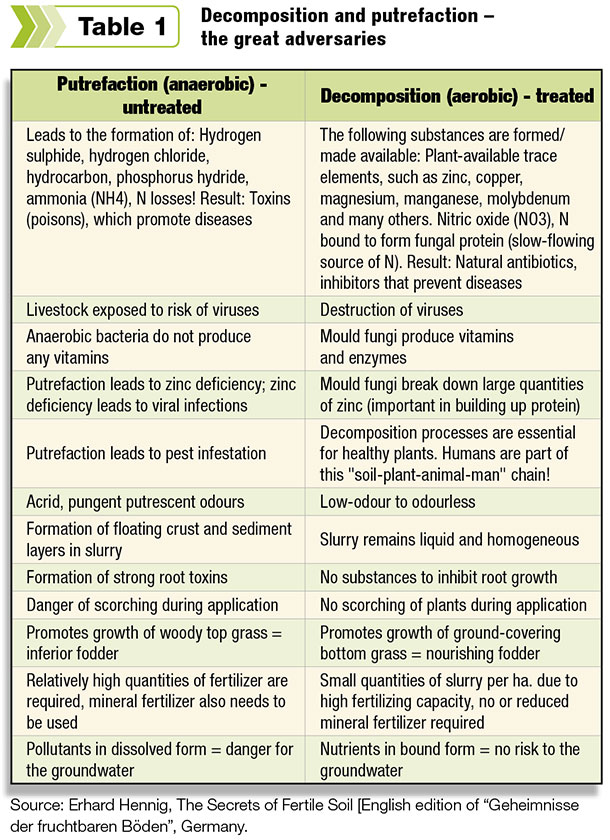

Table 1 outlines the striking differences in the quality and effects of anaerobic and aerobic manure.

While farming areas in Europe and elsewhere in the world have long ago recognized the environmental and agronomic advantages to be gained from aerobic manure treatment, too often farmers in Canada still seem content to allow manure to lose much of its nutrient quality, create odours and potential pathogenic or insect problems, and be more prone to impact on ground- and surface-water quality.

While farming areas in Europe and elsewhere in the world have long ago recognized the environmental and agronomic advantages to be gained from aerobic manure treatment, too often farmers in Canada still seem content to allow manure to lose much of its nutrient quality, create odours and potential pathogenic or insect problems, and be more prone to impact on ground- and surface-water quality.

By drawing upon the experience of dairy farmers in Europe, it has been found that when dairy liquid and dry manures are broken down via an aerobic process (instead of the more common and less desirable anaerobic process), a number of positive benefits are achieved – including a dramatic reduction in the unpleasant ammonia and carbon monoxide odours often assumed as inevitable in conjunction with livestock rearing.

Owing to higher population density, stricter government regulations and a longer history of agricultural use, farmers in Western Europe have been confronted with the need to develop appropriate means of manure handling sooner than has been the case in Canada.

New developments in manure management technology from Europe enable liquid and solid animal wastes to be processed effectively, economically and in an environmentally responsible manner without the requirement for expensive capital expenditures or equipment.

The “aerobic approach” to manure management is increasingly gaining favour around the world, and some of the leading livestock-rearing U.S. states have initiated a shift from anaerobic to aerobic methods of processing animal wastes.

This sustainable approach to manure management is capable of overcoming the main “nuisance” implications commonly associated with animal manure – e.g., odour, pathogens and land, air and water pollution, while at the same time producing a better nutrient-rich end product to apply back on the fields.

Along with the important agronomic benefits of this approach, it has resulting benefits for animal and worker health, methods of composting and field application of manure.

Easy to apply

This approach to liquid manure management is uncomplicated to administer. The products are easy to apply – directly into the effluent channel or alley in the barn (or poured through slatted flooring), where manure is scraped (or carried) to the in-barn holding tank/pit and ultimately transferred to the storage lagoon.

It starts working right away, improving the atmosphere in the barn. For situations where slurry is already in the main storage lagoon, the product can be applied directly into the lagoon where it goes to work.

Economical

An effective solution should be inexpensive, involve no additional capital equipment or operational modifications, lead to a savings on energy use and result in a high-quality end product. PD

-

Derek Pratt

- Managing Director

- Penergetic Canada

- Email Derek Pratt