Here is a summary of each article and updates from authors or participants.

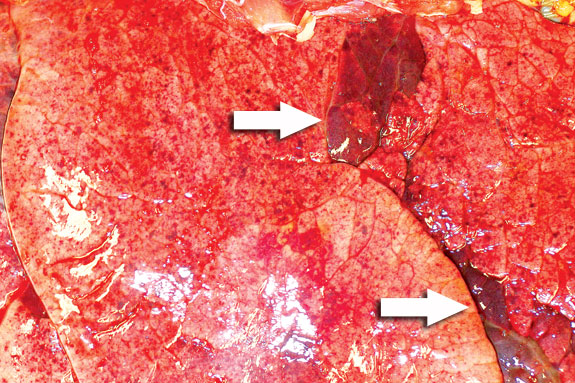

1. Pneumonia in dairy cattle

Published: November 21, 2012

Pneumonia continues to plague dairy calves from 1 day to 5 months old. Dr. Pat Blanchard used cases seen at the California Animal Health and Food Safety Laboratory to show how different types of pneumonia-causing bacteria can infect calves. We asked her:

In the article, you recommended testing for causative agents of pneumonia. At what point should dairy producers consider doing this?

Each dairy producer has a threshold of disease occurrence by type (respiratory) and production class (calf, heifer, cow) that represents the level they tolerate for the condition and its response to treatment.

When this threshold is exceeded, testing should be done.

In cases of pneumonia, guarded deep nasal swabs for bacterial culture, and mid to deep nasal swabs for virus testing should be taken within the first one to three days after onset of respiratory signs and before antibiotic treatment.

However, these cultures are not useful for pneumonia that is caused by aspiration or by E. coli or Salmonella Dublin.

In those cases, animals often fail to respond to treatment and some animals will die.

Fecal cultures within three days of onset can be performed when Salmonella Dublin is suspected, as about 50 to 70 percent of affected calves shed S. Dublin in the feces.

If deaths are occurring, a dead or moribund animal within three days of onset of illness, or three sections of affected lung and a piece of trachea, should be submitted for testing to determine the cause or at least the type of pneumonia (aspiration, blood infection or inhaled), even if prior treatment prevents the laboratory from identifying the bacterial causes.

—Pat Blanchard, California Animal Health and Food Safety Laboratory

2. Consider portable ultrasound to maximize dairy returns

Published: July 21, 2013

Portable ultrasound technology is one of the next rising stars in dairy reproductive management programs. Karen Abbott outlined many of the benefits farms could achieve with its use. We asked:

What is the No. 1 reason producers should consider having a portable ultrasound machine on-farm?

It depends on whom you ask. Ask a producer who is comfortable breeding his own cows and has a comfort level with the reproductive anatomy; they will say the greatest benefit of using ultrasound is early, accurate pregnancy diagnosis.

Learning to manage pregnancy checks using ultrasound is straightforward and entirely possible.

There can be a great cost and time savings to managing the regular pregnancy checks.

Ultrasound confirms pregnancy as early as 27 days by showing a heartbeat; having this intelligence this early with this much certainty is very valuable.

Ask a veterinarian skilled in ultrasound, and they will say the greatest benefit is early identification of problem breeders.

Ultrasound opens up a whole new world over manual palpation because you can actually see the entire reproductive system.

Beyond fetal viability confirmation, you can determine fetal sex, age, ovarian cysts, reproductive pathologies, cycle stage and more.

A skilled ultrasound practitioner can get a tremendous amount of intelligence to assist producers to make the most of their synchronization programs and to better encourage pregnancies.

With the stress milking demands, top producers can be more difficult to get in calf.

Ultrasound can assist the highest-producing cows achieve timely pregnancies, which is incredibly beneficial.

Ask a veterinarian skilled in ultrasound scanning, and they will say the most exciting benefit to the farm is solving breeding problems and using this intelligence to enhance reproductive success.

—Karen Abbott, president of FarmTech Solutions, the exclusive distributor of Draminski Electronics in Agriculture for Canada

3. Considerations for high-inclusion corn silage diets

Published: January 1, 2013

After a challenging cropping season, Robert Larmer with DuPont Pioneer found he was often recommending dairy producers consider feeding more corn silage in their rations.

Of course, a nutrition change is never as simple as just adding a few more buckets of feed to the TMR. Larmer offered a number of things to think about from harvesting practices and storage to monitoring cows and the ration.

What is the biggest mistake you see in herds fed a high-inclusion corn silage diet?

The biggest mistake that I see in my travels on operations feeding a high-inclusion corn silage diet is that these herds have a higher tendency to experience some level of spring acidosis.

I think the main reason we see this is because many herds do not adjust the ration for the increasing starch digestibility that is occurring over time in storage.

Herds feeding high levels of corn silage along with either high-moisture corn or a product like snaplage experience a double whammy as both of the main starch sources in the ration are becoming more rumenally available over time in storage.

Corn silage reaches its peak starch digestibility after about six months in storage, while high-moisture corn or snaplage can continue to increase in starch digestibility for about a year.

Ensure you are working with your nutritionist to evaluate and adjust your high-inclusion corn silage ration on a regular basis to avoid this potential peril.

—Robert Larmer, livestock information manager, DuPont Pioneer

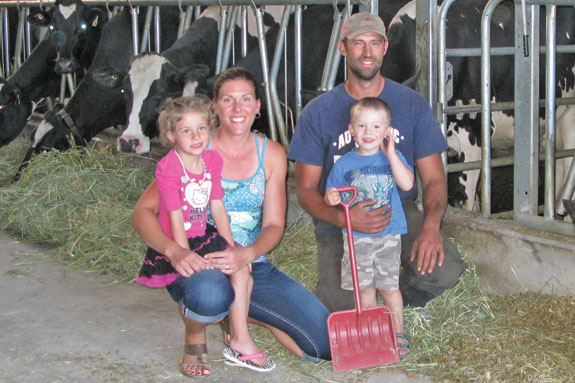

4. Elgersmas pull together to keep their family farm

Published: January 1, 2013

In January, we introduced you to the Elgersma family of Boa Vista Farms in British Columbia.

For anyone struggling to set their New Year’s resolutions, this was an inspiring story about a family that has overcome tragedy and challenges, dug down deep and found a way to continue the family farm established in Canada nearly 50 years ago.

A recent upgrade of new milking facilities made the farm a must-see stop on the B.C. Dairy Expo farm tour later that month.

5. Pacific Agriculture Show

Published: January 1, 2013

Just as we’ve done the past few years, Progressive Dairyman highlighted the upcoming Pacific Agriculture Show, including the BC Agriculture Council Gala, the Pacific Agri-Energy Forum, the BC Dairy Expo and each of the 10 stops in the farm tours.

To get a head start on previewing the show this year, we asked:

What’s new for the Pacific Agriculture Show in 2014?

Two of British Columbia’s most popular dairy extension education events are fast taking shape and scheduled for Jan. 29 and 30.

It begins with the 46th Annual BC Dairy Expo Farm Tour on Wednesday, Jan. 29. This self-guided farm tour, which typically runs from 9 a.m. to 4 p.m., will feature eight progressive dairy farms located throughout BC’s Fraser Valley.

Each farm will showcase an innovative new dairy technology or building design of interest to the industry. In each of the past three years, a total of more than 5,000 farm visits were recorded during the day among the seven to nine farms featured.

The farm tour is followed by the 46th annual BC Dairy Expo Seminar on Thursday, Jan. 30, which is held at the Tradex Exhibition Facility in Abbotsford.

The 2014 seminar will run from 10 a.m. to 12:30 p.m., with the keynote speaker being Dr. Robert Milligan from St. Paul, Minnesota. Milligan will inspire the audience with two talks: “Dairy Farm Business Success in Turbulent Times” and “Tips for Success for Farm Managers.”

Program details and updates for both events can be found at www.agricultureshow.net

—Tom Droppo, dairy industry specialist, BC Ministry of Agriculture

6. Subclinical ketosis, BHB levels and B vitamins

Published: January 1, 2013

In 2013, we started to focus in on dry and transition cows, with the topic appearing twice over the course of the year.

One article, written by Hélène Leclerc, offered B vitamins as a solution to subclinical ketosis as a result of negative energy balance during the transition period.

To learn more about the importance of B vitamins, we asked:

In the article you state: “B vitamins have been identified as being critical during the transition period due to their direct and indirect roles for immune function, liver health, energy metabolism and reproduction.” Are B vitamins just as critical during a cow’s lactation?

It is well known that B vitamins are essential nutrients for all livestock and are part of metabolic reactions of the animal.

In dairy cows, older research from 1928 had demonstrated that rumen microbes do synthesize B vitamins, and it was believed, at that time, that supplementation was not necessary.

Moreover, most of the B vitamins supplied in the diet are destroyed in the rumen, and they need to be protected from rumen degradation when supplemented.

Today’s cows are under much more pressure than cows in the last 50 years. They start to milk at a younger age and produce much more milk.

Recent research has shown a milk production and feed efficiency response to the supplementation of protected B vitamins.

Various feeding studies were conducted in Canada and the U.S. to test a protected B vitamin blend of folic acid, pyridoxine, pantothenic acid and biotin.

The average result of the 23 trials (1,216 cows) did show a significant increase of 1.1 kilogram of milk, 0.09 percent fat and 0.06 percent protein concentration. In addition to these trials, three other studies, run on large commercial farms in California, did show an improved feed efficiency of 2.5 to 5 percent.

Feeding a protected B vitamin blend during the lactation period is a sound, innovative way of increasing your farm profit.

—Hélène Leclerc, technical support and R&D, Jefo

7. Dairy farming around the world

Published: March 21, 2013

It is not every day that dairy producers from Canada, the U.S., Brazil, South Wales and Poland gather together to discuss the similarities and differences of farming around the world, but this is what happened at the global dairy summit held at the inaugural Canadian Dairy XPO in February.

We asked one of the panelists:

What did you learn from this experience?

I learned a great deal from being on the panel. All of the participants were well versed in their numbers and total industry.

They were very resourceful and good at adapting to their own particular market conditions.

They took advantage of all their resources that they had at their disposal.

Regardless of the prices in their own countries, I came away with the feeling that they all would be successful in their economic environments.

There were some differences in environmental, animal health products,

GMOs and, of course, open market versus quota that made things quite different from country to country.

—David Loewith, dairy producer, Ancaster, Ontario

8. New hire Chris Parry

Published: January 1, 2013

Throughout the year, we’ve been introducing some of the dairy industry’s newest employees.

This section is meant to familiarize dairy producers with allied industry members they will meet in the course of doing business. We caught up with Chris Parry to ask:

What has been your best experience in your new role?

There have been many great experiences in my new role, but I think most satisfying is the teamwork here at WestGen.

That teamwork is responsible for many changes in an uncharacteristically short time, and with it, our customers and owners must surely see how the company and its business is evolving.

For example, we’ve launched two new businesses this year – Cryogen Nitrogen Delivery Service and Boviteq West.

Most recently, we’ve re-launched our WestGen brand. It is a fresh new look to signal a recalibration for the next chapter in this company’s proud and immensely successful history.

It is great to feel our western producers responding favourably to the changes. In some cases, it is the stimulus that has nudged a few customers along to reconnect with the company.

The teamwork is also at times a code word for “fun.” There is a real sense we are building something new that this generation of owners and employees of WestGen can be proud of, and that collaborative process is truly fun. All-in-all, I’d say it’s been a really good start.

—Chris Parry, general manager, WestGen

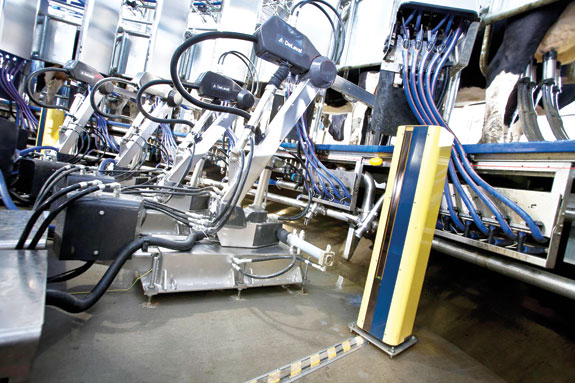

9. New robot facility helps British Columbia dairy farmer do more with less

Published: September 1, 2013

Boasting a herd average of 52 kilograms per cow, Brad Romyn had quite a story to tell of the results he’s seen from building a new milking facility.

The cows were responding well to the added cow comfort the building provided, and a number of people have been curious if that production level was sustainable, so we asked:

Have you been able to maintain your herd’s milk production average of 52 kilograms of milk per cow per day?

When temperatures in the high 30s hit in early July, production did slowly drop down to 45 kilograms per cow.

That production level was still above what I expected the cows to do in the heat.

Reasons for the drop were heat stress and decreased dry matter intake.

As well, we had sold off a number of fresh second-lactation and third-lactation cows for overproduction reasons, so our days in milk started creeping up a little.

We wanted to be in the new facility for a year before we made any changes. Box fans have been purchased recently and will be installed in the spring, which should help keep things more comfortable with increased airflow.

With the temperatures cooling down now, and days in milk back in line with what we’re accustomed to, cows are back up to 50 kilograms with improved components. I believe this to be an achievable production goal as we make improvements to make the cows more comfortable.

—Brad Romyn, dairy producer, Notch Hill, British Columbia

10. Deflate and inflate tires from the driver’s seat

Published: October 11, 2012

Our new technology section features innovative products and systems that have the potential to change the way producers across the country dairy.

One system we introduced you to last fall was the automatic air inflation/deflation (AAID) control system by AgriBrink that allows producers to change tire pressure from the driver’s seat while traveling between fields and roads.

Because we share these products soon after their first release, we asked:

Have you made any modifications to the product in the past year?

Over the past year, AgriBrink has been hard at work modifying and improving its AAID control unit.

These efforts better equip mobile farm machinery to quickly and efficiently select optimal tire pressures whether traveling on fields or roads.

Improvements have included strengthening the design of the compressor for tank units that require high usage, as well as automating the compressor so the operator is not required to perform startup and shutdown functions.

This will reduce compressor wear and reduce energy required to operate the system.

Exciting research in collaboration with the University of Ottawa is under way to demonstrate the reduction of field compaction as a result of optimally deflating tires.

Further, AgriBrink has benefited from the expertise of an engineering firm and a leading agri-business advisory team to streamline the product and marketing plan for the AAID system.

—Jake Kraayenbrink, owner, AgriBrink PD

11. The five W’s of ‘Breakfast on the Farm’

Published: July 20, 2013

On June 22, Canada held its first two official Breakfast on the Farm (BOTF) events; one in Ontario at Heritage Hill Farms, home of the Johnston and Doré families of New Dundee, and the other in Olds, Alberta, at Huntcliff Dairy, home of the Huyzer family.

Lynsay Beavers shared the who, what, where, when and why of BOTF for those who are unfamiliar with this form of dairy promotion. We asked the groups behind the events:

Are you planning to host another Breakfast on the Farm event in 2014?

Alberta Milk is currently looking into supporting another Breakfast on the Farm event for the spring. If there were enough interest from producers to organize the event, Alberta Milk would be interested in providing some support.

—Jacquie Lycka, corporate communications coordinator, Alberta Milk

Plans are currently under way to host a second Breakfast on the Farm event in 2014.

Watch the Farm & Food Care website in the coming months for the date and location.

Photos from the inaugural Breakfast on the Farm can be viewed at Farm & Food Care website (see link above) —Heather Hargrave, Farm & Food Care Ontario

12. Armstrong Manor Farm expands gradually, uses technology

Published: March 21, 2013

Brothers Peter and Philip Armstrong, with Philip’s son, Richard, are the fifth and sixth generation on their Caledon, Ontario, farm.

Over the years, the farm has adopted new technologies to enhance the farm and the cows.

In particular, they have embraced genomics to make better-informed breeding decisions.

As children everywhere are working on their wish lists for Santa, we had to ask:

What is the next piece of technology you’d like to use on your farm?

Armstrong Manor is constantly looking for new ways to improve cow comfort and health.

Over the past year, our somatic cell count has been at a higher level than normal.

With no changes to milking procedures, dry-off protocols or bedding management, it is difficult to pinpoint the issue.

A technology that we have been looking at to improve udder health is the Apollo Milk System from GEA.

This is a system that automatically applies post-dip to the cow and then sanitizes the milk claw before the next cow is milked.

This should reduce the chance of spreading contagious organisms between cows during milking, lowering our somatic cell count.

With automatic dipping, there is a chance that cows may not fully milk out.

This may not be an issue if you are milking three times a day and they will milk out at the following milking; however, it is still a concern.

It should also speed up milking as the person milking would not have to post-dip the cows and would just be required to release the cows when they are finished.

—Philip Armstrong, dairy producer, Caledon, Ontario

13. Wolfes build new barns, life in Manitoba

Published: November 21, 2012

Albert and Alyson Wolfe immigrated to Canada 17 years ago from the Republic of Ireland, where they had a herd of 30 cows but were unable to expand.

Canada offered new opportunities to the Wolfes. They were able to purchase two farms – first one, then a neighbouring farm – and in time, built new facilities for their 175-cow herd. We asked:

What have you enjoyed most about dairying in Canada?

There are quite a few things we enjoy. The stable economic environment has provided us with a good standard of living so we don’t have to seek off-farm employment. There is also less bureaucracy and red tape than what we encountered in Ireland.

—Albert Wolfe, dairy producer, La Broquiere, Manitoba

14. The realities of robotic milking technology today

Published: October 11, 2012

In his first article for us (followed by six more throughout the year), Francisco Rodriguez introduced himself and a topic he is very passionate about: automatic milking systems.

As he described the realities, we thought it would be good to ask about the myths that are circulating around the industry.

What is the largest misconception you’ve heard in relation to automatic milking systems?

“With robots, I don’t have to spend time in the barn. They will take care of my cows for me.”

This, of course, is not true. Investing in robots gives producers the opportunity to have more flexibility, better quality of life and get better-producing more milk with less labour and healthier cows.

However, an appropriate combination between skills, knowledge, management and spending time with your cows is what makes a robotic milking facility great.

Just look at how several AMS dairies have broken numerous production records this year, thanks to their robots but also their keen ability to maximize their resources to manage the herd.

As technology continues to advance in the barn, the ability to manage with precision and by exception will help farmers to focus on appropriate strategies to maximize productivity and profitability of dairy farms.

The technology is there and will continue to get better – but not without the determination of the producers themselves.

—Francisco Rodriguez, dairy management adviser, DeLaval

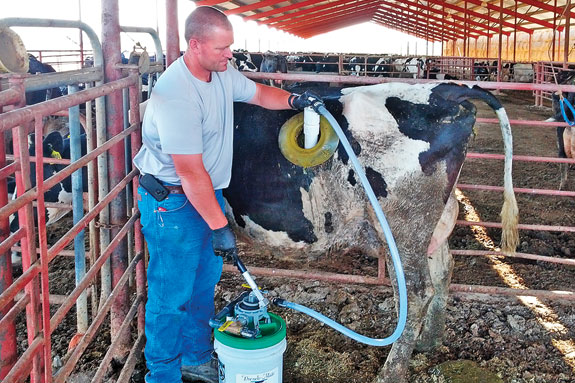

15. Rumen fluid extraction made easy

Published: January 1, 2013

Another popular new technology for the year was Rumen-Mate, a self-contained rumen fluid extractor and drenching system.

This product provides an easy solution to using rumen fluid from a healthy cow to jumpstart the rumen of an unhealthy cow.

This article was one of the product’s first introductions in Canada and was soon followed by live demonstrations at a number of farm shows and events. PD