Larry Chase, professor at Cornell University, recently spoke about studies of shredlage and how these findings compare to typical kernel processing. The following is an overview of his presentation.

Shredlage processes corn similar to other kernel processing equipment. The main difference is that shredlage shreds the material instead of chopping it. This leads to thoroughly ground kernels and particles that seem to be fluffier than normal. These particles are also longer that what you would find in typical kernel processing. This would predict an increase in starch and fiber digestibility and in neutral detergent fiber (NDF).

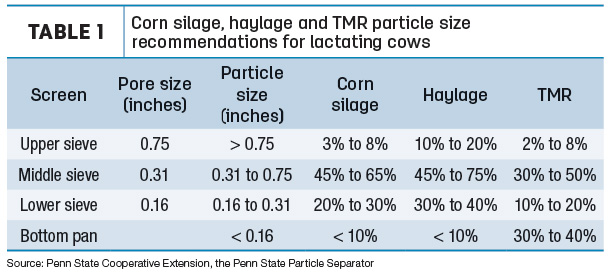

Researchers have developed a few ways to quantitatively score kernel processing. One is through the Penn State shaker box. The Penn State Particle Separator (PSPS) was developed to create a simpler, on-farm method to measure feed particle size rather than the cumbersome laboratory method. In this method, the box can be equipped with multiple sieves. Each sieve will allow a certain size particle to go through. The original particle separator contained two sieves: 0.75 and 0.31 inch. The 0.75-inch sieve captures the particles that would be buoyant in the rumen, while the 0.31-inch sieve collects forage that will be part of the forage mat in the rumen but will be broken down faster with less cud chewing.

In 2013, a 0.16-inch sieve was released that focuses on separating small forage pieces that are often, but not always, high fiber in nature. The 2002 model of the PSPS involved a 0.05-inch sieve that focused on small particle digestibility. Table 1 includes a breakdown of particle size recommendations for lactating cows.

While the ideal particle size is still up for debate, it is important that adjustments be made to the particle length throughout harvesting. There must be someone monitoring the shredlage chopper to make adjustments if needed. If there is someone monitoring the chopping, this allows for adjustments to ensure the feed is coming in at an excellent kernel processing score more often.

Multiple studies have been conducted to see the effects of shredlage on dairy cattle. The University of Wisconsin – Madison performed two trials. Both trials had similar results, showing that shredlage had a greater theoretical length of cut and a greater amount of particles left on the top screen than conventional kernel processing. Researchers found an increase in the total tract diet digestible starch and the silage digestible starch. This means that there was more starch found throughout the digestive system, leading to more energy to the cow and more nutrients to the milk.

Another study by Cornell University found no significant changes in milk production. The silage was stored for months before feeding, which may have contributed to some of these results. Researchers found no difference in the packing density and little differences in the composition of the feeds. To see how the feed types affected cattle, researchers had four pens with 32 cows per pen. Throughout the trial, each pen was given both types of feed at different times. Researchers looked for differences in dry matter intake, milk production, milk composition, feed efficiency, fecal starch and total tract starch digestibility but found no major differences between the two feeds.

Dairy One also conducted an on-farm trial comparing shredlage to traditional kernel processing. The other feed ingredients remained the same for both groups. This study consisted of two pens with 152 cows per pen. As with the Cornell study, there were very few differences found between the two pens. Dry matter intake, milkfat, milk protein and fecal starch were relatively the same for both feeds. This study did, however, show a 2.2-3.2-pound higher milk production for the cattle on the shredlage diet.

In 2014, a farm survey was conducted on 69 farms ranging in size and milk production. Shredlage was used by 61% of these farms for the study. Most of these farmers found that they reduced the amount of hay or straw in the rations. About 45% reported there was an increase in milk production, and about 39% reported no change to the milk production. Only about 6% of the farmers reported a decrease in milk production, and the remaining farmers were unsure. It is important to note that these results are not quantitative but based off of the farmers’ impressions.

With all of this being said, what does this mean for the dairy and feed industry? There are many questions that still have not been answered about shredlage. Currently, only certain types of harvesters can be equipped with the shredlage attachment, and we need more information on particle size guidelines. The harvesting does need to be monitored to ensure the greatest quality of product. The findings of milk production have been so varied that it is difficult to say whether or not shredlage is beneficial to milk production. Overall, it is clear that shredlage reduces the amount of supplemental hay and straw needed, decreasing overall costs. We may not yet know all the benefits of using shredlage over conventional kernel processing, but the decrease in cost alone may be enough for many dairy farmers to make the switch.