When it comes to input costs, we are all aware of the rising price tag on fuel and labor. It’s no surprise that you will also likely see an increase in any custom services you hire out, such as manure hauling and harvesting.

But you have more control over that bill than you may think.

As a consultant who digs into both the books and operational efficiency, one of the areas where I often see opportunity to reduce costs and work smarter is with the custom crews dairies hire to get manure out and crops in. Just because you don’t own the equipment or manage the labor doesn’t mean you can’t influence how things are being done that impact the custom work invoice you will have to pay at the end of the season.

There are three key areas to keep a watchful eye over when it comes to controlling the cost of custom work.

1. Focus on fuel

Each trip a truck or tractor makes down the road or across a field matters, especially when fuel prices are at record highs. This is the time to tighten up efficiencies. As an owner or manager, take a few moments to observe the crew as they do their work. Are there trucks and drivers waiting in line to unload? That idle time is expensive. Talk with the crew manager about why there is a lag in unloading. Perhaps there are more trucks than needed for the job, or there is a time-eroding delay that’s throwing the entire team behind.

Filling fuel tanks is another area where both time and money can be saved. If there is a line to fuel up, a solution may be a portable filling tank with a larger pump to get trucks filled up faster. For one particular manure hauler, it was taking 15 minutes to fill each semi with fuel. The investment in a larger fuel pump enabled them to fill each truck in half the time.

Clarify fuel surcharges with the custom operator on the front end. Ask questions about how the charges are applied. Now may be the time to shop around for more competitive rates.

2. Manage labor needs

Finding good employees has not gotten any easier. That’s why it’s important to maximize the value of the labor force and plan strategically around available labor and the requirements of the job. One approach to this is to prioritize the fields that are the farthest distance away from the dairy when the workforce is the strongest. When you know there are times the crew is slim, schedule the smaller, closer fields.

Another way to look at labor efficiency is making sure the employee’s skill set meets the requirements of the job. I’ve seen unskilled new hires put in charge of operating filling equipment during manure hauling, which leads to massive delays in workflow. Manure hauling season is not the time for on-the-job training. Put the best-qualified people in the right seats.

3. Right-size the fleet for the job

Too many or too few trucks for manure hauling or crop harvesting can rack up custom work costs with no benefit in return.

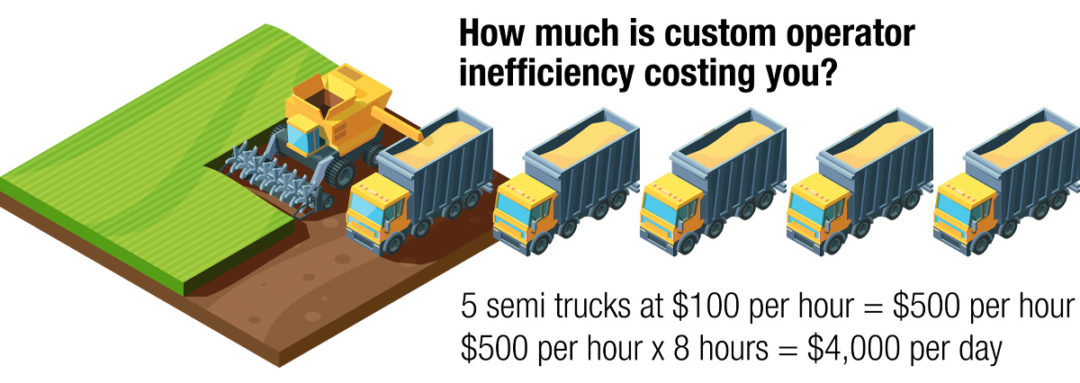

What we don’t want to see are a half-dozen semis waiting to unload. Let’s do the math: If the crew is overstaffed and there are five semis waiting to unload at any given time, and each semi is costing you $100 per hour, that is $500 per hour of cost that you will be paying for later with nothing to gain in return. If that’s the case, send a driver home or to a different job. On the contrary, if it’s harvest time and the chopper is waiting for trucks, have a ready list of drivers and trucks that can be called in to keep things moving.

It’s not just about saving time and money. Let’s look at the bigger picture of putting up quality feed in the ideal harvesting window. For example, a dairy may get 50 acres of corn silage harvested in one day. If one more truck can be added in an efficient way, they could get an additional 25 acres chopped before sundown. A more efficient harvest yields better quality, more consistent feed throughout the year and, ultimately, more milk in the tanker.

How to have the conversation with your custom operator

To make the most efficient use of both fuel and labor, the best approach is to sit down with the custom operator before the cropping season and pre-plan the equipment and truck needs for both manure hauling and custom harvesting. Look back at historical records of how many trucks or employees were necessary to complete the job. If you don’t have those records, start tracking them. This will enable both the dairy producer and custom operator to make good decisions as a team so both can operate efficiently and control their costs.