Considering the current economic situation with higher interest rates and increasing building costs, some producers are delaying building plans and large investments. They are looking to solve the lack of labour issue while creating a better work-life balance – and therefore, still have automated milking systems top of mind. But what about a retrofit? Let’s discuss the benefits of an automated milking system retrofit and the impact on productivity, longevity and sustainability.

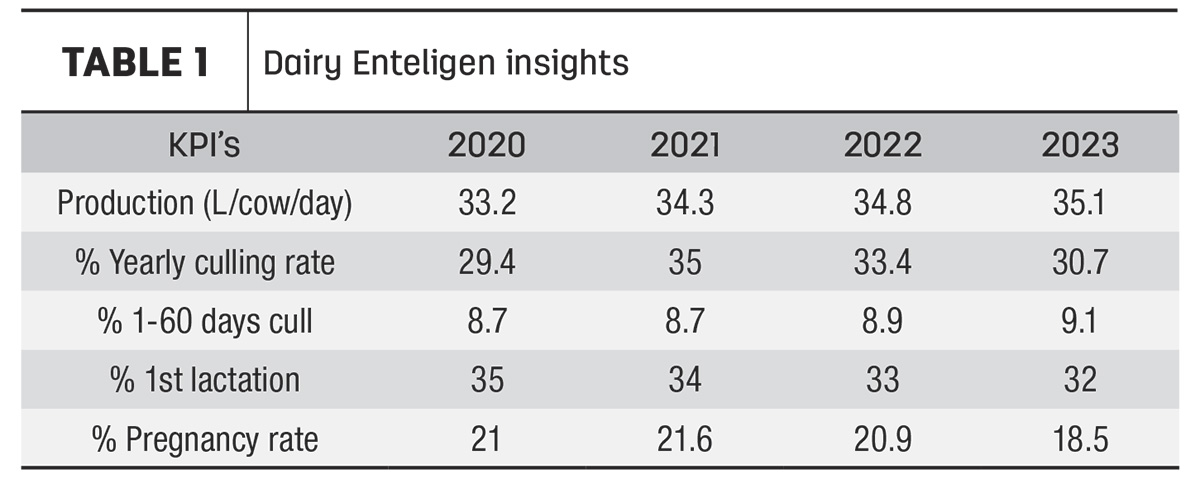

Using real herd data, we analyzed the following key performance indicators (KPIs):

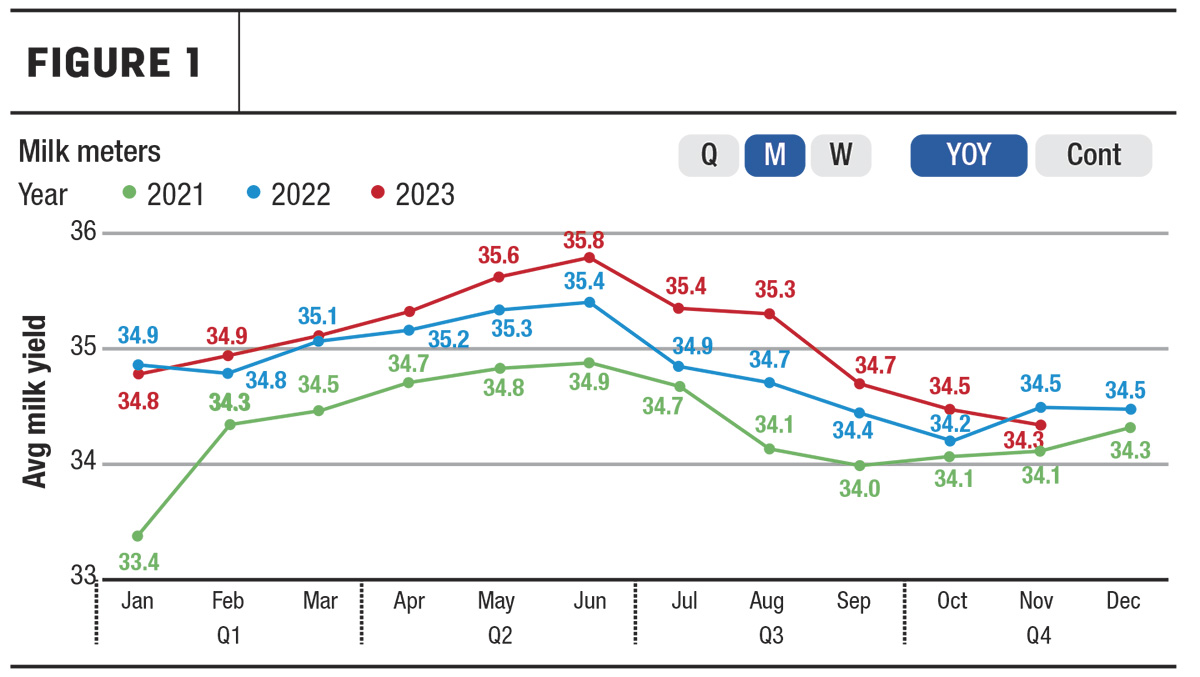

- Productivity: In evaluating productivity, we considered two simple KPIs – litres per cow per day and kilograms of milkfat produced per cow per day. Not including a full year of transition following automated milking system installation, the trending average was a 3 litre per cow per day increase, representing an additional $2.70 revenue per cow per day or an additional $900 on 305 milk, using an average milk price of 90 cents. We want to ensure that milkfat production is also trending the same way and validated that the average was a 0.15 kilogram per cow per day increase.

- Longevity: Commonly, cows in their fifth and sixth lactation are the most profitable and efficient, according to CowSignals' Master Trainer Joep Driessen. Hence, lowering culling rate by keeping healthy, higher-producing mature cows can have a positive impact on your herd's lifetime productivity and total net revenue. Two to five years after an automated milking system retrofit, data suggest at least a 5% reduction in culling rate can be expected. Another interesting trend was a 2% reduction of cows culled before 60 days in milk (DIM). Expected loss per early lactation cull would be over $3,000, including the replacement cost less than the salvage revenue, treatment and disposal costs, and lower milk revenue.

- Sustainability: Many KPIs can be evaluated to demonstrate sustainability. More milk per cow explained in No. 1 is a key contributing factor. With lowering the cull rate in No. 2, the number of replacement animals needed decreases, which has a sustainable impact. Reducing the number of replacement heifers has a significant impact on the costs since the average heifer-raising investment is well above $3,800 per head. Heifers must reach the correct maturity at calving to obtain the most profitable lifetime production, considering the right mature bodyweight. Owners will often purchase quota and expand their herd size a few years after a retrofit. The herd data analyzed did not necessarily show a reduction in first-lactation animals in the herd; however, the increase in milk production and total milk production is still sustainable and a benefit to the farm’s bottom line.

Feeding in the automated milking system also allows for targeting specific nutrients to individual cows, therefore more closely meeting her requirements, hence giving us the opportunity for improving feed efficiency, a key contribution to sustainability. By moving nutrients from the total mixed ration (TMR) to the robot feed, we can target early-lactation animals to support higher production for peak periods and reduce concentrates mid- to late lactation without impacting the persistency. The investment of nutrients in the correct stage of lactation is more sustainable.

Moving away from direct animal effects, comparing automated milking systems to parlours or tiestalls can show a decrease in water and electricity usage. Studies show a range of water use in robots and conventional milking systems. Robots can be as low as 8 litres of water per cow per day, parlours as low as 10 litres per cow per day and tiestalls 12 litres per cow per day. Farmer reports of electrical use with robots also vary – some farms report a noticeable decrease while others see an increase in their electric bill. Robots have shown a trend to reduce electricity use with newer models. These possible changes to water and electrical usage, and the cost saving they can bring, are important factors when considering a possible change to an automated milking system.

Having the data to benchmark your herd before and after a retrofit is important because on-farm milking software usually changes with automated milking system installations. Maintaining software that consolidates data from multiple milking or herd management software systems can be a benefit to evaluate and visualize your KPIs over time. See Table 1 and Figure 1 showing important data points to look at during the transition to a retrofit. However, these data are output for over 300 Canadian herds on Dairy Enteligen, not necessarily retrofit barns.

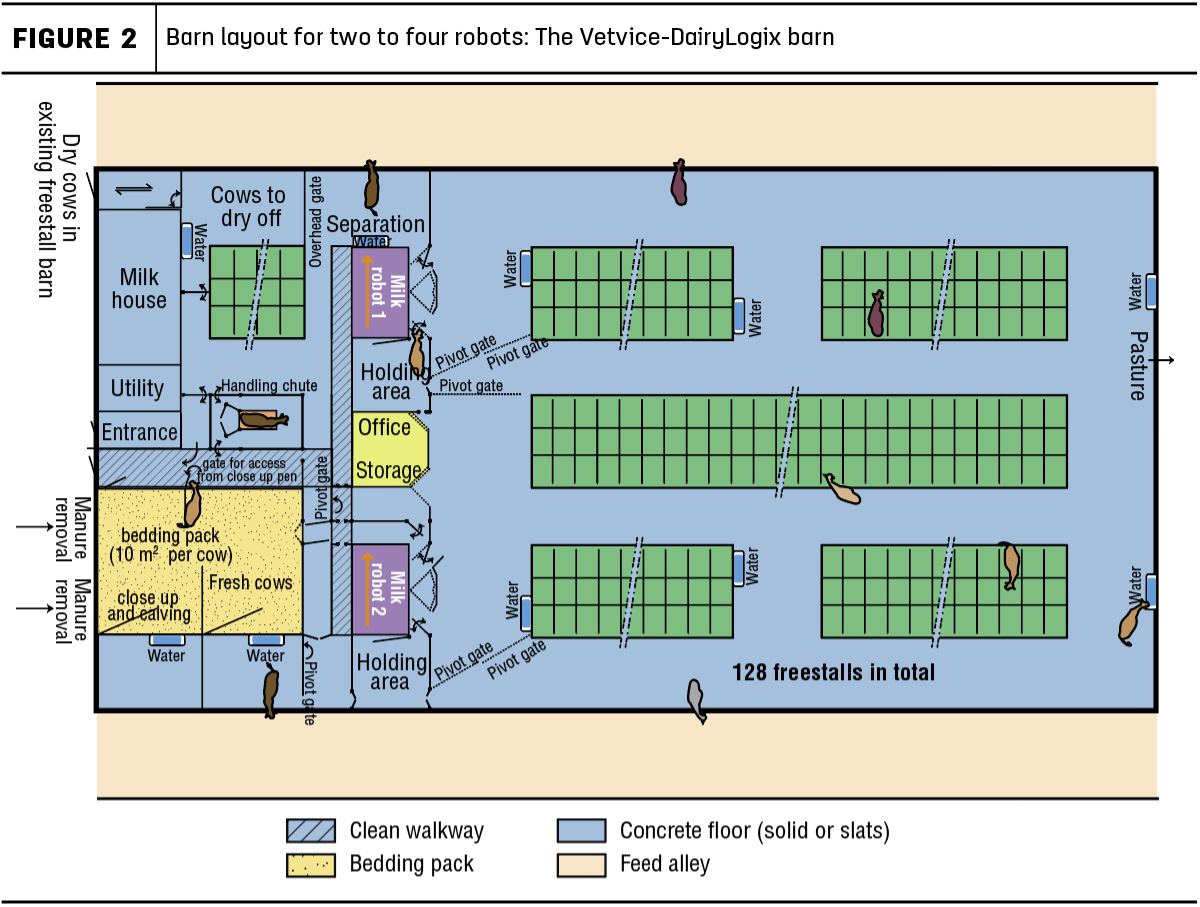

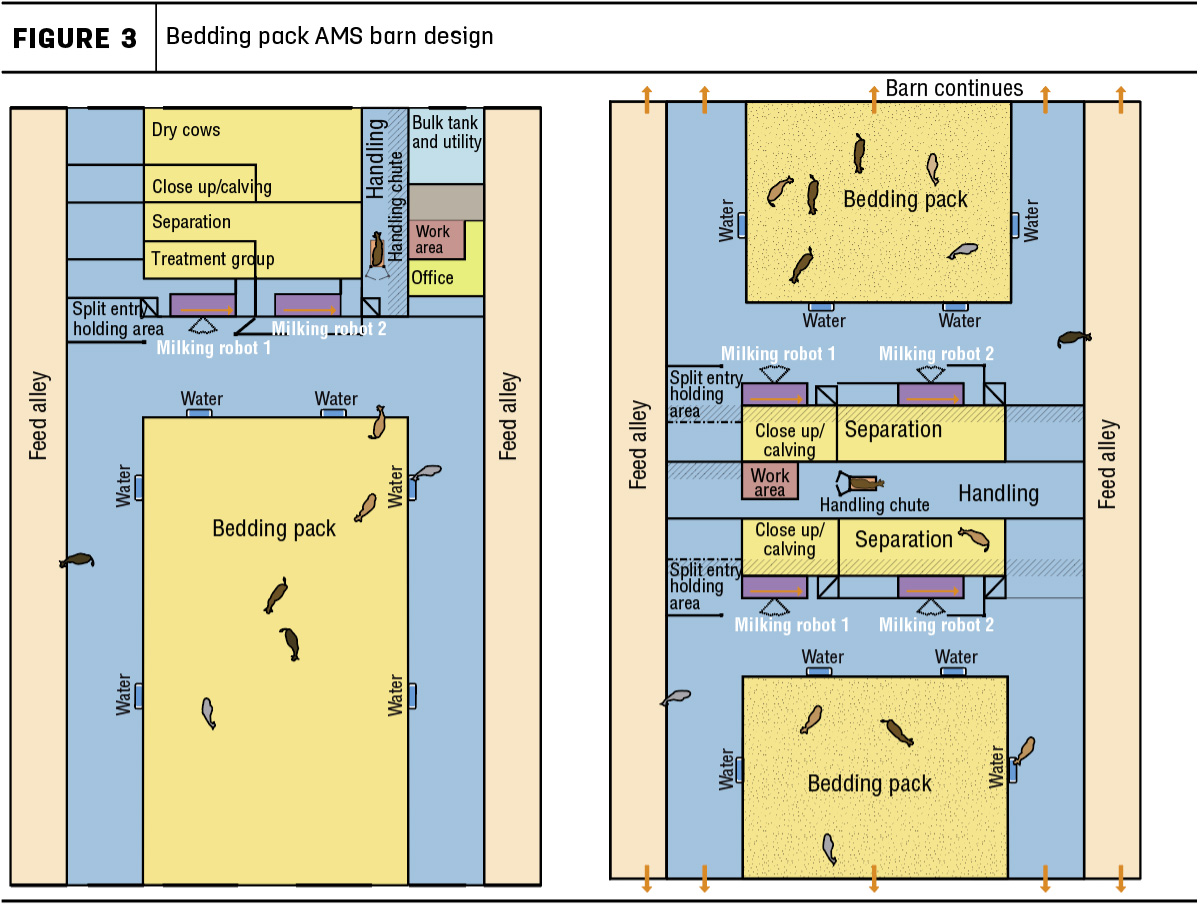

Cow flow and overall comfort are key to a successful retrofit barn with an automated milking system. Figures 2 and 3 show different CowSignals automated milking system barn designs. Your retrofit should have proper alley width to maximize cow flow to and from the robots as well as feed and water access. Proper ventilation to minimize heat stress during summer months and reduce cows congregating under fans or in front of robot (blocking flow) is also something to consider during an automated milking system retrofit.

Hoof health is important in an automated milking system barn. To allow cows to comfortably walk to the milking robots, it is key to set up a hoof bath that can easily be conducted multiple times a week. It is also important to consider adding a treatment area to ensure timely and improved cow care that one person can manage. Overall, the simple fact is that milk production will increase if cows are lying in a stall rather than standing for an average of one-and-a-half hours in the holding area. In addition, less standing leads to improved hoof health, which can lead to less culling due to feet and legs.

This barn layout allows one person to do daily chores and deliver cow care to improve cow longevity. The central cow treatment area is between dry and fresh cows and connected to the special needs group so all animals can be conveniently brought to the chute. If we make the task convenient to complete, it’s much more likely the task will be done on time, and cows’ lives will be lengthened.

Robots can work in a variety of layouts and housing types. Bedding pack barns support improved production, longevity and sustainability while keeping the investment in a retrofit barn low.

If we consider a 100-cow herd, the expected financial benefits from only a few KPIs can include $90,000 more in milk profits ($900 per lactation) and $6,000 saved due to fewer early-lactation culls. Would $96,000 a year along with improved sustainability cover the costs of your robot retrofit over a 10-year period? Evaluations for barn designs, proper robot location and minor cow comfort enhancements can result in a successful retrofit. Correctly analyzing a variety of KPIs, such as productivity, herd lifetime production and sustainability, using data consolidation software can show that automated milking systems retrofits are viable and lead to financial gains and management advantages.