Artex Barn Solutions brought more than 60 of its North American dairy customers and dealers to China in late October to celebrate the company’s 40th year in business.

The barn equipment fabricator based in Abbotsford, British Columbia, has been manufacturing its products near Tianjin, China, for the past several years.

John de Jonge, the company’s president, says he wanted his clients, dealers and industry friends to see first-hand what he saw when he first visited China in 2005.

“When I first came here, they were very hospitable,” De Jonge recalls. “I came with samples. Within a 24-hour period, they made all of my samples and the quality was excellent. The amount of commitment, dedication, eagerness and engagement I found blew me away.”

Since that first visit, De Jonge has visited the country more than 60 times, almost once every six weeks, as he shifted his company’s manufacturing production from Canada to China.

Now he’s also in a business partnership with a Chinese company, East Rock Farm Tech, which is the dealer for all his company’s products in Asian markets.

“Our approach is a little bit different. We’re growing a network of like-minded companies so that we can provide added value to our end customers who are dairymen throughout the world,” De Jonge says.

Artex and eight other companies recently formed the Global Dairy Institute, a consortium of companies that offer a full range of services to create a successful modern dairy operation from the ground up.

In all, the recent tour included more than 100 participants from 13 countries. During the four-day event, the group toured the company’s manufacturing plant; several large-herd, foreign-investment dairies; Nestle’s new Dairy Farming Institute; and popular Chinese cultural sites. PD

PHOTOS

PHOTO 1: Artex visitors were the first international group to tour Nestle’s new Dairy Farming Institute in Harbin, China. The new facility for the Chinese dairy industry aims to educate and certify Chinese farm owners and workers about modern dairy production. The site includes a three-story facility of classrooms, laboratories, sleeping quarters and a cafeteria for faculty and employees who stay for course work for weeks at a time. The site also includes three dairy facilities of various sizes, each with their own parlor. Each of the dairies represent example farms for Chinese dairy producers to pattern their own construction after – a progressive size farm (200-400 cows), a large farm (600 to 1,200 cows) and a mega farm (up to 3,600 cows). The mega farm is the only of the three not yet built. The others are in milking operation as of earlier this year.

PHOTO 2: Workers paint over the welds of this recently fabricated headlock with zinc to protect them from corrosion. More than 100,000 pounds of steel are used each day at the factory to make the company’s products.

PHOTOS 3 & 4: A female milker at Huaxia Dairy near the suburbs of Beijing prepares one of 3,200 cows for milking on an 80-stall rotary. The dairy was one of several large-herd dairies the group visited. Its cows are housed in a cross-ventilated freestall barn.

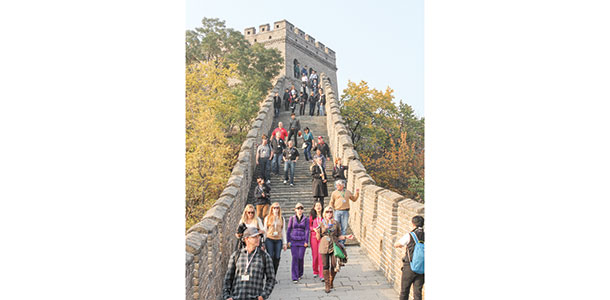

PHOTO 5: Event participants walk along a stretch of the 3,800-plus-mile Great Wall of China on the first day of the tour. Photos by Walt Cooley.

Walt Cooley

Editor

Progressive Dairyman