Celebrating 10 years of Top 25: The top 25 of 2018 For a decade, Progressive Dairyman has presented readers with an annual list of the top 25 best-performing articles. In those 10 years, our online readership has increased nearly 2,000 percent.

We’ve gone to a weekly enewsletter distribution and, just this year, we upgraded our digital edition platform, bringing you even more options to read content on the go.

Read on to find out which articles brought in the most pageviews from Oct. 1, 2017 to Oct. 1, 2018, and find follow-up questions and responses with the authors and producers featured.

1. Dean Foods terminating milk contracts effective May 31

Published: March 8, 2018 Extra enewsletter

A milk market is the major economic pipeline for dairy farms, and when that pipeline closes, financial and personal crises arise. Such was the case in late March when Dean Foods announced the plan to close seven fluid plants, impacting the milk markets for more than 100 dairy farms.

After several stressful months, most dairy farm families found alternative milk markets, although some made the decision to exit dairy farming.

In addition to covering the news, Progressive Dairyman followed the path of a southern Indiana dairy farm family, the Kelsays, as they eventually made the difficult decision to develop a dairy exit strategy. (See article, “Kelsays moving on from dairy following ‘perfect storm,’” from the Oct. 1, 2018 issue.)

PHOTO: The Kelsays: (left) Joe and Amy Kelsay with their children Jack, Jenna and Josie; and Russ and Liz Kelsay with their sons Grant and Rhett. Photo courtesy of Kelsay Farms.

2. Herrema Dairy runs 900 cows with 12 robots, three people

Published: July 19, 2018 print issue

Last year, Herrema Dairy built a 15-row robot barn to milk 720 cows and house 180 dry cows. Together, farm manager Cory Craig and robotic farm manager Caleb Herrema quickly took efficiency to a whole new level, running the facility with only three people while optimizing both milk production and box time. The dairy, in Fair Oaks, Indiana, also features a unique positive-pressure ventilation design.

Q. Nearing one year in the new barn, what would you say has been the biggest challenge of managing an automated facility? Also, what do you believe is your greatest achievement since moving into this barn?

“I think the biggest challenge is trying to take management techniques from the robot barn and implementing them in the rotary barn, such as labor management, treating cows as individuals and not as a herd, etc.

“I think our biggest success is the amount of labor – or lack thereof. Caleb has been very successful at implementing and managing such a small number of employees to get all of the tasks done on a daily basis.

We have achieved all of the personal benchmarks I set for the robot barn regarding somatic cell count, heat detection, milk production and cull rate ... and quite frankly, Caleb made it look easy. The whole experience has exceeded my expectations.”

PHOTO: Cow-level cooling is provided by high-velocity recirculating fans and foggers over the cow beds. Photo by Peggy Coffeen.

—Cory Craig, farm manager, Herrema Dairy LLC

Read the article: Herrema Dairy runs 900 cows with 12 robots, three people

3. ‘Raising these calves saved me’: The story of Michigan dairy widow Amanda Leik

Published: Nov. 9, 2017 Extra enewsletter

Progressive Dairyman readers found Amanda Leik’s story filled with encouragement and hope. The Michigan dairy farmer lost her husband, Denny, in February 2015. She made the choice to continue farming alongside the couple’s three young daughters.

Progressive Dairyman readers found Amanda Leik’s story filled with encouragement and hope. The Michigan dairy farmer lost her husband, Denny, in February 2015. She made the choice to continue farming alongside the couple’s three young daughters.

“I had many people reach out and tell me I was an inspiration to them,” Leik says. “That was very humbling. I had no idea they felt that way.” People also took the time to say how proud they were of Leik and her girls. “For me, it was just surviving and doing what I’ve always done,” she says. “My three daughters are my whole world, and raising them to be strong women will be my greatest accomplishment. It’s all about setting a good example of how hard work and perseverance pay off in life.”

The Leik family continued to work hard in 2018.

“My daughters and I are happy and doing very well,” she explains. “My kids enjoy working with me every day on the farm.” The girls showed animals at the county fair this summer while their mom made some changes to her calf operation. “I decided to keep my heifers due to decreased dairy cattle prices,” Leik says. “I bred them to a beef bull and am raising them as cow-calf pairs. I calved 20 this summer, and it went perfectly. The calf gains are exceptional, and it’s going really well.”

PHOTO: Amanda Leik’s three daughters are heavily involved in 4-H. From left to right, with mom Amanda in the back, are Emily, age 9, Elaine ‘Lainey,’ age 6, and Kelsey, age 11. Photo provided by Amanda Leik.

—Information provided by freelance writer Karena Elliott

Read the article: ‘Raising these calves saved me’: The story of Michigan dairy widow Amanda Leik

4. Robot meets rotary at Hoffman’s Happy Holsteins

Published: April 12, 2018 Extra enewsletter

Among the very first in the country to install a robotic rotary, the Hoffman family from Peshtigo, Wisconsin, built a 40-stall automated rotary parlor in late 2017. Coming from a double-10 step-up parlor, the transition to automation cut milking time in half and reduced labor down to only two people per milking shift: an operator in the parlor and a fetcher bringing up cows. They continue to milk 3X, just as they had in the past.

Q. Coming up on a year in the robotic rotary, how are the people and cows settling in?

“Things are going a lot better. We are waiting on a software update but have fewer and fewer slowdowns. There are now four of these [GEA robotic rotaries] in the U.S. and Canada. Of all the ones in North America, we’ve got the highest attachment percentage at 91 percent.

Back in March, when the dealer came and did an update to the cameras with the new style, our attachment rates went way up and keep getting better.

“The cows are taking to it better, and employees are settling in. We are now milking over 600 cows as heifers have freshened in and replaced the ones culled when we first started. The heifers do really well. Some kick a little at first but calm down after a week, which is a shorter time than it took in the old parlor. The challenge is always trying to get more milk.”

—Kent Hoffman, Hoffman’s Happy Holsteins

Q. With so much data now at your fingertips, how do you use it to manage the herd?

“The main things I’m looking at on a daily basis are the herd summaries, keeping an eye on milk production to make sure no cows are dropping off hard, which is one way to tell if they are getting sick or not. Also, I look at conductivity. Once every three months, a company tests milk, which we mainly look at for somatic cell count to find chronic cows.”

—Kent Hoffman

According to Mark Proeber with Kozlovsky Dairy Equipment, there are now three more DairyProQ robotic rotaries operating in the U.S., with a few more coming online in the near future.

Read the article: Robot meets rotary at Hoffman’s Happy Holsteins

5. If your current vet isn’t a woman, odds are the next one will be

Published: Jan. 19, 2018 print issue

For some time now, the number of females attending colleges of veterinary medicine has surpassed the number of male enrollees. While the current nationwide enrollment stands around 80 percent women, most vets who retire in the coming years will be replaced by a female practitioner.

This article describes the changing face of veterinary medicine, according to Dr. Jessica A.A. McArt, assistant professor of ambulatory and production medicine at Cornell University’s College of Veterinary Medicine, and Dr. Angela M. Daniels of Dalhart, Texas, the owner of Circle H Headquarters LLC.

Q. Why do you think this piece resonated with readers?

“Equality, in all respects, is at the forefront of current politics,” McArt says. “I think this piece resonated with readers as it speaks to the long-term struggle of gender equality, even in the veterinary profession, in which the number of graduating females surpassed males over 30 years ago.”

“I think the article spoke directly to the many conversations that have taken place over the years,” Daniels adds. “Good conversations about additional topics like maternity leave, raising children while practicing, how to balance family and career demands (have followed). It is obvious to our industries the women wave has hit, so now is the time to step up and have the open dialogue. The speculation is over.”

Female veterinarians continue to face bias practicing their profession within the dairy industry. And the challenges often stem from producers who question their physical ability or their level of experience.

“The bias is that young practitioners lack experience,” Daniels says. “So I often tell students if they want to be a great dairy or beef practitioner, they should work on a dairy or ranch or feedlot.” McArt agrees, noting “Female vets often face bias that they do not have the experience or ability to consult on management-level issues.”

Daniels has actively mentored young practitioners for years and encourages them to learn the industry from the starting position on up. “Your input will then be practical and achievable,” she says. She also tells vet students to not fall on their faces trying to show how much they know but, instead, show how much they care.

As for having physical assistance, take it. “Having a few extra hands around isn’t a bad thing with a C-section,” Daniels says. “This is a good time to teach, ask questions and find out what is really going on at the farm. A lot can be learned by working side by side.”

PHOTO: Jessica McArt says female veterinarians may need to do certain jobs a different way, but they can certainly still handle the tasks. Photo provided by Jason Koski, Cornell University Marketing Group.

—Information provided by freelance writer Karena Elliott

Read the article: If your current vet isn’t a woman, odds are the next one will be

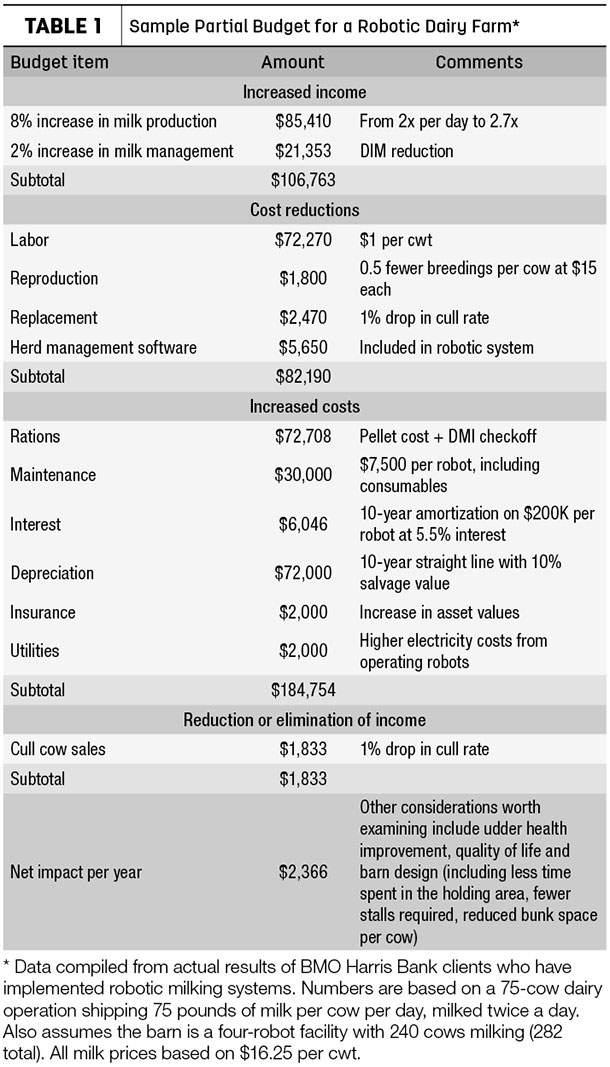

6. What’s the true return on dairy robots?

Published: Feb. 15, 2018 Extra enewsletter

Though it was once estimated the adoption of automated milking would yield a labor savings of $1.50 per hundredweight (cwt), that number may be too high and even double what some dairies are actually seeing.

After reviewing the data from their clients who have implemented robots over the past couple of years, Craig Rogan and Brad Guse from BMO Harris Bank are seeing an actual labor savings of about 75 cents to $1 per cwt. They attribute this to increased time spent on robot maintenance and herd management, with hired labor still needed for other tasks like feeding and cleanup.

The lenders further noted dairies relying on labor savings to pay for the capital costs may need a 10-year amortization, not a seven-year amortization as initially thought.

Q. What is the magical number at which robots can cash flow in today’s market, based on milk price and production?

“There does not appear to be a magical formula to arrive at a number a dairy can cash flow in today’s market environment. In our experience, the keys to success lie in an operation’s ability to manage efficiency on a couple of levels.

“1. Operational efficiency. This is the ability to manage operating costs in relation to income. In other words, managing the day-to-day bottom line. From what we’ve seen, the best operations are running expense ratios below 70 percent. Their focus is on all costs, with the use of monthly variance reports as their tool to analyze actual-to-budgeted expenses.

“2. Capital efficiency. Where capital is deployed has become critical in today’s economy. Using an automatic milking system requires additional capital, which makes it even more important to manage efficiency. We often look at milk revenue per robot when measuring capital efficiency, which ties closely to milk per robot. In our view, the goal should be milk per robot in excess of 5,500 pounds. This will, in turn, push your capital efficiency numbers.

“Having said all of this, it really comes down to one thing: The best managers have a lower breakeven cost of production than their peers. They do that by being efficient operators while making smart capital deployment decisions.”

—Craig Rogan, vice president of business banking at BMO Harris Bank, and Brad Guse, BMO Harris bank senior vice president, agricultural banking. Member FDIC.

Read the article: What’s the true return on dairy robots?

7. Martins bed robotically with sand

Published: Jan. 11, 2018 Extra enewsletter

Micah, Japheth and Clement Martin – along with their families – decided to combine their dairy herds and build a new facility. Milky Way Dairy near New Paris, Indiana, is now one of the most automated precision dairies in the country, with robotic milking, cow monitoring, sand-bedded flush system, flexible stalls and a robot that delivers sand bedding to the freestalls.

Q. Have you set up the capability for the bedding robot to message you when there is a problem?

“While the bedding robot can be set up to send alerts, we do not have this set up on the bedding robot at this time,” Japheth Martin says. “Since we made changes to make it more compatible with sand, we haven’t had any issues. We are around enough to see if there is a problem and have been able to correct any issue we have had.

We do have alerts set up on our milking robots because we need to make sure they are running around the clock without interruption. Our milking robots and herd alert systems give us operational messages, information on the cows, individually, and dashboard readings to see at a glance how our herd is doing. This has been especially helpful as we have been trying new things with our feeding program to balance today’s dairy economics with production.”

Q.What’s the next automated technology you’re hoping to implement in your operation? When do you hope to add it to the farm?

“We would like to add a robotic feed pusher in the future, but we have no immediate plans to add technology. Everyone is feeling the pressure of low milk prices, and having this facility and the technology we have invested in helps us stay positive,” Martin says.

PHOTO: The key to keeping manure out of the back of the stalls is to keep plenty of sand in the front of the stalls. That’s the Astor bedding robot’s job two to three times a day. Photo by Sherry Bunting.

—Information provided by freelance writer Sherry Bunting

Read the article: Martins bed robotically with sand

Courtesy photo.

8. New facility positions Brooks Farms for bright future

Published: April 1, 2018 print issue

Creating a comfortable environment for cows in the barn and parlor was a top priority for Zoey Brooks when she began planning for a new facility and expansion that would grow the herd from 230 cows to eventually 700. Her efforts to achieve this included automated technologies like alley scrapers and a feed pusher to remove the need for skid steers in the barn.

Creating a comfortable environment for cows in the barn and parlor was a top priority for Zoey Brooks when she began planning for a new facility and expansion that would grow the herd from 230 cows to eventually 700. Her efforts to achieve this included automated technologies like alley scrapers and a feed pusher to remove the need for skid steers in the barn.

Sand-bedded freestalls and automatically adjusting curtains and fans add to the amenities. The double-20 parlor was also designed with quietness and cleanliness in mind.

Q. Earlier in the year, you mentioned one challenge with the new facility was encouraging cows to leave the quiet, comfortable parlor on their own after milking. What methods have you tried to improve cow flow in this area, and has it been successful?

“We made a few changes to encourage cows to leave the parlor, which cumulatively have improved cow flow:

“1. Return lanes (which were cobblestone) were ground down.

“2. We brought in an independent consultant who checked for stray voltage and found one light in the holding area that was causing issues.

“3. The biggest change we made was adjusting our feeding time/order and our milking order. Prior, our feeder fed cows before milking time (primarily because it avoids gate swings and problems with cow traffic). We found this was interfering with the cows’ rest time (they would get up and eat early, lie back down and then be kicked up again in an hour to go to the parlor).

“We backed up feeding times to work in conjunction with milking times. Fresh feed is now dropped while the cows are in the parlor, so they have the incentive to return to the pens quickly. But as we only feed once daily, this has really only helped the morning shift. Changing the feeding order also allowed us to milk cows in the proper order, with fresh cows being milked first. While cow flow is still not where we want it to be, it has improved.”

PHOTO: The Brooks family’s new facility was built to be a “welcoming place,” according to Zoey Brooks. Photo provided by Forest Construction Inc.

—Zoey Brooks, Brooks Farms

Read the article: New facility positions Brooks Farms for bright future

9. Four Midwest dairies share secrets to repro success

Published: March 15, 2018 Extra enewsletter

At the 2017 Midwest Dairy Day, four dairy operations shared strategies, tips and protocols for meeting reproduction goals. Heintz Badger Valley Farm in Houston, Minnesota, and Stempfle Holsteins in Maynard, Iowa, both have a 33 percent pregnancy rate. Leix Farms in Montfort, Wisconsin, has a 34 percent pregnancy rate, and Schilling Farms in Darlington, Wisconsin, achieves an impressive 46 percent pregnancy rate.

At the 2017 Midwest Dairy Day, four dairy operations shared strategies, tips and protocols for meeting reproduction goals. Heintz Badger Valley Farm in Houston, Minnesota, and Stempfle Holsteins in Maynard, Iowa, both have a 33 percent pregnancy rate. Leix Farms in Montfort, Wisconsin, has a 34 percent pregnancy rate, and Schilling Farms in Darlington, Wisconsin, achieves an impressive 46 percent pregnancy rate.

Q. What are each farm’s reproduction goals for 2019?

Schilling Farms

The Schillings are expanding the amount of beef semen they are using to capitalize on the beef market calves. They are also utilizing genomic testing to create the amount of heifer replacements needed to sustain the current herd size. The Schillings are exploring the possibility of using activity/rumination collars and breeding in-house, but they will only pursue it if it shows a return on investment while maintaining performance.

Heintz Badger Valley Farm

“We are not changing much – just steadily working on the little details,” Doug Heintz says. “With good growth rates on the heifers, we will be breeding heifers at 13 months to keep an even number freshening in the March to June timeframe when we have been historically calving fewer.” He says the challenge is getting cows to conceive during the heat of the summer and while on pasture.

Stempfle Holsteins

In 2019, the Stempfles want to continue to rely more on cows coming into natural heats and making even more individual-based decisions on breeding cows. They will continue to work on individually choosing the “best” time to breed each cow and the best approach to achieving that goal.

“Not one breeding policy fits all cows. There are many factors that influence conception: age and lactation, body condition and milk production, to name a few,” Paul Stempfle says. “We also hope to be more active in flushing what we feel are our best animals, and capitalizing on their genetics.”

Leix Farms

“In 2019 it is going to be my goal to use at least 50 percent beef semen in the milk cows,” Ross Leix says. “I am planning on being able to do this by increasing sexed semen use on the highest genetic milk cows.”

PHOTO: Stempfle family photo. Photo courtesy of the Stempfle family.

—Information provided by freelance writer Kelli Boylen

Read the article: Four Midwest dairies share secrets to repro success

10. A more heat-tolerant Holstein is on the way

Published: Feb. 22, 2018 Extra enewsletter

Genetics may be a new tool for decreasing the summer slump of milk production and reproduction as semen is now available from two bulls bred by the University of Florida that possess the haplotype for a shorter, sleeker hair coat known as “slick.”

Genetics may be a new tool for decreasing the summer slump of milk production and reproduction as semen is now available from two bulls bred by the University of Florida that possess the haplotype for a shorter, sleeker hair coat known as “slick.”

According to Peter Hansen of the University of Florida, cows with the slick mutation are better able to regulate body temperature, experience less milk production loss and maintain better fertility during periods of heat stress. The two Holsteins, Slick-Gator Blanco and Slick-Gator Lone Ranger, are heterozygous, meaning there is a 50 percent chance their offspring will be slick.

The university is working to develop homozygous bulls that will produce 100 percent short-haired progeny.

Q. Since the article was published, are there more genetics available to dairy producers to incorporate the slick trait in their herds? Also, what type of response have you had from dairy farmers?

“My experience to date has been that there is a lot of interest for the bull from producers outside the U.S., in parts of South America and Asia where heat stress is a major problem.

There are also several breeders in the U.S. interested in using slick semen to increase the genetic merit of slick Holstein bulls. We are doing that too, and hopefully there will be a wider range of bulls to select from in the next few years.”

—Peter J. Hansen, University of Florida

According to Michael Vieira with A Legacy Genetics (ALG), a Puerto Rico-bred bull is headed to Hawkeye Breeders in Iowa to begin collections. A Defiant son, El Remanso Sinba-PLN-Red, the first homozygous “slick” Holstein bull offered commercially, will be available to ALG’s foreign markets first, then domestically in later 2019.

PHOTO: Breeder Rafy López (Puerto Rico) with El Remanso Sinba-PLN-Red, the first homozygous “slick” Holstein bull available commercially. Photo provided by Michael Vieira.

Read the article: A more heat-tolerant Holstein is on the way

11. 7 signs calves are headed down a bad health path

Published: March 8, 2018 Extra enewsletter

In light of the recent research regarding the correlations between pre-weaned calf health and the heifer’s future productivity in the herd, minimizing the impact disease has on calves is a major focus of many calf-raisers today. The goal with this article was to help producers identify sick calves early on before it sets them back too much or spreads to their herdmates.

Q. When it comes to identifying and treating sick calves, what is one piece of advice you can never stress enough?

“Be present in the moment. When you monitor and treat calves, make sure they are your top priority and you’re not distracted by something else. Calves often show subclinical signs of illness before they crash. Does something look, feel, smell or sound off?

When you’re present in the moment, you will notice those subtle signs of a calf heading down the wrong path. For example, something might catch your eye when you walk past a calf, so you stop, observe and evaluate. In most cases, early intervention will save you and the calf a lot of stress.”

PHOTO: Observation is an essential component of proactive disease management. Take time each day to watch for calves showing signs of sickness. Photo by Mike Dixon.

—Ann Hoskins, calf products coordinator, Vita Plus Corp.

Read the article: 7 signs calves are headed down a bad health path

12. Dairy farmers dig out from roof collapses

Published: April 10, 2018 Extra enewsletter

Last April, a winter storm dumped nearly 3 feet of snow in the Upper Midwest, leading to barn roof collapses on dozens of dairies in northeast Wisconsin. Blizzard conditions prevented milk pick-up in some areas. Even after the storm passed, dairies were still not in the clear, as the heavy snow loads continued to threaten freestall structures.

Local highway crews and fire departments were called in to help with safely clearing rooftops, and fellow dairy farmers helped each other out moving and relocating cattle as needed.

Necessity inspired creativity at Kinnard Farms in Casco, Wisconsin. Dairy operations manager Shaun Hardtke came up with the idea to break up the snow and ice on the roof of their cross-ventilated barn by spreading salt with a crop-dusting plane.

Q. Was using the plane to dust salt on the barn roof successful? Also, what did you learn from this experience that changes your protocols or preparedness plans going into this coming winter?

“Dusting the salt on the barn roof immediately had a positive effect on the snow load. The snow immediately started to melt, and the water wept off slowly. It did not make any large sections of snow slide off or clear out instantly, but I do think it created a honeycomb effect in the snow sheet, which made the roof much lighter.

Then, as it was melting, there was a place for the water to weep through the snowpack and drain off more quickly. What we were noticing before spreading the salt was: When the snow from the top of the roof started to slide down, it added more weight per square foot toward the center and the eave of the roof, and that’s when we started to see the roof become stressed. I think spreading the salt prevented any more roof from collapsing than what had already happened.

“Going into this winter, we are currently working on doubling up all of the purlins on the south face of the roof that took it the hardest. Since the roof on our barn is a solid 20 acres in size with a very low pitch and the screws being placed on top of the ribs, manually removing the snow load in the future with shovels or blowers would not be an option, not to mention a safety hazard.

We have always built our barns to the highest snow load ratings in order to prevent issues like this from happening, and we feel this prevented this situation from being much worse than what it was. Currently, we plan to move forward by relying on the extra support we are adding to the buildings.”

PHOTO: The Stahl dairy farm in Kewaunee County experienced a roof collapse on part of the barn and await further damage at a weakened point in the rooftop, as indicated by the red arrows. Photo courtesy of Stahl Brothers Dairy.

—Shaun Hardtke, dairy operations manager, Kinnard Farms

Read the article: Dairy farmers dig out from roof collapses

13. What drives financial success on a dairy?

Published: Feb. 7, 2018 print issue

With so many management variables affecting a dairy operation’s financial performance, what separates top-performing herds from all others? In this article, Steve Bodart, a senior dairy consultant at Compeer Financial, summarized a collaborative study conducted by Compeer and Zoetis.

The study analyzed 425 farm-year records (over a 10-year period) from herds in Iowa, Michigan, Minnesota, Ohio, South Dakota and Wisconsin. Herd sizes ranged from 500 to 4,700 head and averaged about 1,071 lactating cows.

The study analyzed 90 variables, identifying six key items that distinguished top-performing dairy operations from their peers: somatic cell counts, energy-corrected milk, net herd replacement costs, death losses, pregnancy rates and heifer survival rates.

Q. With dairy farm financial stress continuing through another year, which of those factors were especially influential on a dairy herd’s financial performance in 2018?

“2018 has brought its own set of challenges. Although the financial drivers on a dairy have remained the same, there are some that have taken on additional importance, including net herd replacement cost.

“Cow values – for both cull cows and cows sold as dairy replacements to other producers – have dropped. Cull cow prices dropped approximately 100 to 150 dollars per head this year. Cows sold to other dairy operations are down 300 to 500 dollars per head, if there’s available markets for them.

“A herd with the same turnover rate as last year is seeing a major increase in their net herd replacement cost. The decreased profit margins of 2018, combined with the cost of raising a heifer holding steady, results in it taking more milk production before a cow has recovered her growing costs and is helping lower the cost of production.

Second-lactation cows are typically producing 15 percent more milk than first-lactation heifers, while third-lactation cows are producing 10 percent more milk than a second-lactation cow.

“With decreasing cull cow prices it is more important than ever to have a minimum of 35 percent of the herd in their third lactation or greater. By maximizing the amount of the herd in a third lactation or greater, the herd is able to further reduce its cost of production by reducing the inventory of heifers that need to be raised.”

—Steve Bodart, senior dairy consultant, Compeer Financial

Read the article: What drives financial success on a dairy?

14. 6 tips to improve feeding accuracy

Published: Nov. 2, 2017 Extra enewsletter

It is important to talk with your feeder often to ensure they are following the correct diet formulation set by you and your nutritionist. This article provides six ways to set your feeders up for success and achieve a high level of precision and accuracy when loading ingredients into the TMR mixer.

Q. If you could add a seventh item to this list, what would it be?

“In our previous article, we provided some practical recommendations to improve loading accuracy of feeders, mostly by using feeding management software records and by improving communication with feeders. However, even on dairies where feeders are extremely proficient at loading, the TMR may not reflect closely what was formulated. This is explained by uncertainties in the nutrient composition of ingredients.

To minimize this error, monitor the nutrient composition of all new commodities by sending representative samples to certified labs. Place special emphasis on evaluating dry matter (DM) of high-moisture commodities, and work with your nutritionist to determine when to reflect DM changes in the recipe.

Based on feeding management software records, some dairies are failing at this; 17 percent of dairies kept the dry matter of corn silage in the recipe unchanged through a 12-month period. In the San Joaquin Valley of California, most dairies rely on the scheduled visits from their consultants to evaluate the DM of commodities and adjust recipes.

Feeders should be trained to notify managers whenever obvious changes in the appearance of commodities are noted. For example, skilled feeders can pick up changes in an ingredient’s density during loading. Train your feeder to recognize the importance of commodities’ DM, and empower them to, at least, monitor commodities visually.”

PHOTO: Talk with your feeder often to ensure they are following the correct diet formulation set by you and your nutritionist. Photo by Rúbia Lopes.

— Noelia Silva Del Rio, dairy extension specialist, University of California – Davis

Read the article: 6 tips to improve feeding accuracy

15. Four misconceptions of pre-fresh heifers

Published: Aug. 23, 2018 Extra enewsletter

At the 2018 Vita Plus Calf Summit, Pat Hoffman challenged dairy farmers to dig deeper into four commonly held beliefs around pre-fresh heifers in order to better understand the unique needs of these animals and improve overall health, performance and longevity.

While 21 days is often hailed as the ideal pre-fresh period, Hoffman encouraged extending that to make up for early calvings due to sexed semen, heat stress and genetics. He also explained corn silage isn’t the single cause of fat heifers but rather the lack of a high neutral detergent fiber (NDF) forage.

He further explained freshening heifers at a younger age does not guarantee a greater return on milk yield, and dietary salt does not appear to be as closely tied to udder edema as once thought.

Q. You mentioned the effects of oxidative stress on pre-fresh heifers, leading to issues like udder edema and inflammation. Can you explain what oxidative stress is and its potential effects on dairy animal health?

“Oxidative stress is nothing new in animal biology, but it is a relatively new term in dairy cattle nutrition. When any animal is transported, moved from pen to pen, exposed to diseases, fed bad feed, etc., the animal’s immune and metabolic systems will ultimately produce what are called reactive oxygen species.

It’s a normal biological process. However, an animal’s body needs to control the level of reactive oxygen species, otherwise cell damage and inflammation can occur. Reactive oxygen species in an animal’s body are controlled or balanced by a number of key enzymes or directly by nutritional antioxidants. While many nutritional antioxidants exist, vitamins C and E are classic examples.”

PHOTO: Heifers at the feedbunk. Photo by Peggy Coffeen.

—Pat Hoffman, dairy technical specialist, Vita Plus

Read the article: Four misconceptions of pre-fresh heifers

16. Dairy immigration reform eBook

Published: Oct. 19, 2017 Extra enewsletter

Progressive Dairyman’s special e-book, “Immigration reform,” covered a wide range of immigrant labor issues, from the changing political landscape and enforcement actions, such as workplace raids and I-9 form audits, to providing advice on how to secure work visas and provide incentives to keep current farm employees.

There were several congressional attempts to reform U.S. immigration policies in 2018. For dairy, the best option appeared to be the Agricultural Guestworker Act, introduced by U.S. Rep. Bob Goodlatte (R-Virginia). However, as the year came to a close and lawmakers became even more politically entrenched in preparation for midterm elections, virtually all attempts to address border security issues while assuring an adequate supply of dairy workers had failed. Watch for ongoing coverage of this issue in our news section online and in print.

View it online (Dairy Immigration reform eBook).

17. Maximize milk quality through cow comfort

Published: Feb. 1, 2018 Extra enewsletter

This article explores cow comfort factors that most impact milk quality, talking through sand- and compost-bedded barns as well as pasture systems. The author encourages producers to guard against heat stress, regardless of housing type.

Q. You advise dairy producers to ‘sweat the small stuff’ – to pay attention to the details. What small detail do you think is most overlooked when it comes to milk quality and cow comfort?

“There are many small details that should not be ignored on farms, but the overlooked ones vary between farms, so I can’t list with certainty what the most important ones are to everyone. We often ignore or excuse what we consider to be insignificant events in a cow’s life and expect her to rebound to her full potential, but in reality these events actually have lasting effects on milk production and quality.

To a cow, several ‘smalls’ can quickly turn into ‘bigs,’ and we usually don’t even realize it. So let’s take an example that is probably similar to something all producers have had on their farm to see how easily ‘smalls’ can snowball.

“A first-calf heifer calves in during a rainy week in April in a wet pasture. Because the rain has created problems everywhere on the farm, you forgot to give that cow her coliform mastitis booster, and she didn’t get milked until the next milking four hours later – and thus went without a clean udder for that long.

She was put in a pen with other fresh cows – but also sick cows harboring mastitis pathogens looking for a new udder to call home. You haven’t been able to bed as frequently as normal because your bedding delivery was delayed.

“One week later, she’s getting settled into her new career as the rain stops and the heat and humidity rise. The fans and sprinklers get turned on when you arrive at the barn at 5 a.m., when it already feels like 90 degrees. Your milker detects clinical mastitis that afternoon, and her milk production decreases 25 percent by morning. You treat her appropriately and she lives, thanks to your care, but she becomes just an average-producing cow that got fresh cow mastitis and never produced enough or stayed without mastitis long enough to permanently stay off the potential cull list.

“Which of those small things started the track down Mastitis Road? It’s hard to say, but each of them played a role, and each of them would not have been thought of as a big deal to most people. But to her, all of these events were meaningful – individually and together. Of course, some of these things are not even in a producer’s control (although many are), but what we can control should be the best it can be to help create an environment of less ‘smalls.’”

PHOTO: Sand-bedded stalls should be cleaned regularly, and producers should make sure dry sand remains at curb height. Photo courtesy of Amanda Stone.

—Amanda Stone, extension dairy specialist, Mississippi State University

Read the article: Maximize milk quality through cow comfort

18. 9 ways to make overcrowding work

Published: May 24, 2018 Extra enewsletter

Nutritionist Ron Munneke works with some herds that can overcrowd three-row pens by as much as 40 percent and still average well over 100 pounds of milk per cow per day. He believes the secrets to their success are as follows: Never overcrowd the pre-/post-fresh pens, group first-calf heifers separate from mature cows, frequent feed pushups, comfortable stalls, excellent heat abatement, provide a minimum 2 inches of waterer space per cow, focus on foot health, feed rations that aren’t sortable, and keep cows clean.

Nutritionist Ron Munneke works with some herds that can overcrowd three-row pens by as much as 40 percent and still average well over 100 pounds of milk per cow per day. He believes the secrets to their success are as follows: Never overcrowd the pre-/post-fresh pens, group first-calf heifers separate from mature cows, frequent feed pushups, comfortable stalls, excellent heat abatement, provide a minimum 2 inches of waterer space per cow, focus on foot health, feed rations that aren’t sortable, and keep cows clean.

Q. In addition to the nine concepts you explored in the article, are there any additional keys you believe can minimize the negative effects of overcrowding?

“The additional key is to minimize the time cows spend outside of the pen. The University of Wisconsin vet school did a survey of herds that averaged over 90 pounds of milk. They found from the time the gate opened to let the first cow out of the pen until the gate closed after the last cow returned was 90 minutes.

It would be better if that was closer to 60 minutes, but that can be an especially tough goal to hit in overcrowded situations.”

PHOTO: With careful management, some dairies are able to maintain high levels of production despite overcrowding. Photo by Peggy Coffeen.

—Ron Munneke, dairy nutritionist, Purina Animal Nutrition

Read the article: 9 ways to make overcrowding work

19.The State of Dairy for 2018

Published: March 12, 2018 print issue

In its annual comprehensive “State of Dairy” report, Progressive Dairyman looked at the U.S. dairy industry from coast to coast, interviewing dairy farmers and industry leaders. Some regions had ample feed supplies, while others faced drought.

Much of the country has surplus milk, while California was uniquely flush with processing capacity. The previous year’s cautious optimism was replaced by widespread financial concern and worry.

There was hope for a mid-year reset – which never materialized – further complicated by burdensome global milk supplies and trade wars with some major U.S. dairy export customers. Those factors drove milk prices down and forced a growing number of dairy farmers out of business.

Policymakers tried to step in, improving the Margin Protection Program for Dairy, providing direct financial assistance to producers hurt by tariffs and launching a new Dairy Revenue Protection income insurance program. Calls for some sort of supply management program grew louder, although legislative action was minimal.

Lower feed prices projected somewhat better income margins as the year came to a close, but early forecasts for 2019 milk prices remain little changed from 2018. Progressive Dairyman will publish its annual snapshot of the U.S. dairy industry in early March of 2019.

ILLUSTRATION: llustration by Kristen Phillips.

Read the article: The State of Dairy for 2018

20. Robotic milkers and feed system help sons return to family farm

Published: Nov. 16, 2017 Extra enewsletter

Linda Hanson and her husband, Mike, have three sons – David, 26; Matthew, 24; and Steven, 21. The family milks about 120 registered Ayrshires and Holsteins, and farms about 2,700 acres. They built a robotic milking facility in 2016 to expand the herd and allow for all three sons to return to the operation, if they chose.

Q. What are the farm’s goals for 2019?

“As 2018 is coming to an end, we continue to look at the future with positivity and try to remain optimistic for the dairy industry in 2019,” says Matthew Hanson of Good-Vue Ayrshires of Goodridge, Minnesota.

The Hansons say they will continue to learn and grow with the changing times and rapid advancement of technology in the dairy industry as well as the world as a whole. He says they will also continue using the technology they have already invested in to continue improving their herd’s production, reproduction, health and overall efficiency of the cows to maximize profits and increase cash flow.

Additional goals they have set for 2019 including beginning using genomics and other genetic options more often to help advance herd genetics at a faster rate and utilize lower-end genetic cows and heifers as embryo recipients or use cheaper beef semen with them.

“On the crop and field side of things, we want to begin looking at ways we can better manage our land to make sure we are keeping the soil fertile and in the best health possible to keep fields profitable and productive for many more years to come,” he says.

“We have also set a goal to open ourselves more to the public to show that we, as dairy farmers, do our best to provide healthy and safe products while using sustainable practices on the farm as well as focusing on the health and safety of the cattle.”

PHOTO: The Hanson family pictured here includes three generations of Minnesota dairy producers. From left to right: Steven, Lynn, Mike, Linda and Matthew Hanson. Photo provided by Matthew Hanson.

—Information provided by freelance writer Kelli Boylen

Read the article: Robotic milkers and feed system help sons return to family farm

21. Mycoplasma mastitis: An emerging disease concern

Published: Dec. 14, 2017 Extra enewsletter

Changes in dairy herd management, primarily herd expansion, have turned mycoplasma mastitis into an emerging disease. Not only does mycoplasma cause mastitis, but it also affects other body sites in the cow, causing pneumonia, lameness, arthritis or metritis.

Changes in dairy herd management, primarily herd expansion, have turned mycoplasma mastitis into an emerging disease. Not only does mycoplasma cause mastitis, but it also affects other body sites in the cow, causing pneumonia, lameness, arthritis or metritis.

The disease is considered a contagious agent and is not only transmitted in the milking parlor but also transmitted from nose-to-nose contact between cows. Key risk factors for mycoplasma mastitis are the introduction of new animals and stress.

Q. Has there been any research released in the past year to help identify better prevention or risk factors that could potentially impact the prevalence of mycoplasma mastitis?

“A few new studies have been published recently. It should be noted these are regional studies. Additional studies are needed to confirm these results.

“A new research study* in a Belgian dairy herd identified the use of a breeding bull and the absence of a calving pen as risk factors for the presence of Mycoplasma bovis (M. bovis) in dairy herds.

Herds with breeding bulls had 4.7 times higher odds of a positive bulk milk tank test than herds without a breeding bull, and herds without a calving pen had a 3.7 times higher chance of a positive bulk milk tank test than herds with a calving pen. The study authors indicated the importance of the breeding bull and calving pen in the between- and within-herd spread of M. bovis may have been underestimated in the past.

“A new research paper has also been published studying semen as a potential risk factor for M. bovis. A Finnish study* describes how M. bovis was introduced into two closed and adequately biosecure dairy herds through the use of contaminated semen during A.I., which was associated with mastitis outbreaks in both herds; the authors of the paper note this is the first study of its kind.”

PHOTO: Not only does mycoplasma cause mastitis, but it also affects other body sites in the cow, causing pneumonia, lameness, arthritis or metritis. Photo provided by Larry Fox.

—Christina Boss, senior global product manager, Thermo Fisher Scientific

*References omitted but are available upon request. Click here to email an editor.

Read the artricle: Mycoplasma mastitis: An emerging disease concern

22. Identifying the four D’s of scours and how to treat it

Published: May 31, 2018 Extra enewsletter

Scours remains a major problem among calves, not only due to death loss but because it negatively impacts calves’ future performance and opens them up to other diseases that could kill them or severely impact their growth and development. The purpose of this article was to give producers a roadmap for understanding and treating scours.

The article pays particular attention to rehydrating those calves and goes into detail about choosing and using electrolytes, which are critical in this process.

Q. When you work with farms that struggle with calf scours, what is one thing you wish those farms knew six months earlier?

“These are difficult times in the dairy business. Every farm has calves that needlessly die due to scours and dehydration. I wish calf producers were consciously aware of the total cost of their ‘current program’ in terms of start-up costs, labor, ineffective treatments and dead calves because calf mortality is a huge drain on profitability.

“Even one dead calf is one too many if a more effective program could have kept these calves alive. Low-priced electrolytes typically have the highest cost in terms of dead calves. Changing scours protocol is one of the most profitable decisions a calf producer can make because it can yield immediate results in lowered death loss.

The cost to implement an effective new program is zero – in fact, it pays because a reduction in death loss of only 1 percent translates into a net profit increase of about 1,350 dollars per year for every 100 hutches.”

PHOTO: When treating scouring or dehydrated calves, remember 1-2-3: one bottle for scours, two bottles for moderate dehydration and three bottles for severe dehydration with appropriate products. Doing this keeps more calves alive. Staff photo.

—Drew A. Vermeire, nutritionist, Nouriche Nutrition Ltd.

Read the article: Identifying the four D’s of scours and how to treat it

23. North Carolina’s Reverence Farms utilizes grazing, line breeding and nursing herd

Published: March 29, 2018 Extra enewsletter

Hue and Suzanne Karreman aim to treat all animals, people and their environment with reverence and respect. Their 400-acre farm supports 60 Jersey cows, their youngstock, a handful of beef cows, 150 feeder pigs, 125 St. Croix ewes, 150 turkeys, 6,000 pastured broilers and 700 laying hens.

Q. What are the farm’s goals for 2019?

Q. What are the farm’s goals for 2019?

The Karremans are in the process of adding a new milking parlor with a walk-through single-six (with ability to expand to 10-stall) which will be much more labor-efficient; they have been milking in buckets in a flat parlor in the feed lane of their compost-bedded pack barn. They are also switching from sawdust to a chopped straw pack, which harbors fewer bacteria in the humid Southern summers.

The walk-through parlor allows the whole mixed-age herd to run together and walk through the parlor safely. All the animals, including some beef cows and yearling heifers, can walk through the parlor and not stop, saving time sorting cows. This streamlined process will allow them to run one big herd of 60-plus adult animals, including calves and yearling heifers, in one herd, dramatically increasing rest periods, which will increase pasture productivity.

They continue working on taking more than 100 acres of woods and turning it into functional pasture with selective logging, understory grinding and then following with pigs, sheep and cattle in a rotation that constantly adapts to what the land needs most in terms of animal impact. The partial shade of the remaining tree canopy allows the predominantly cool-season perennials to remain vegetative much longer and provides lower-temperature pastures, radically reducing heat stress and increasing milk production and average daily gains (ADGs) in the summer.

They are continuing to work toward a mostly spring-seasonal herd, but the hot and humid summers take an exceptionally fertile cow to get bred in 95ºF heat with nearly 100 percent humidity, so they have to calve earlier in the spring than they’d like (early March is freezing rain and still winter) and still have some fall-calving cows.

PHOTO: The 400-acre farm supports 60 Jersey cows and all of their youngstock, including the bull calves, which are raised for meat and the best are sold as breeding bulls. Photos courtesy of Suzanne Karreman.

—Information provided by freelance writer Kelli Boylen

Read the article: North Carolina’s Reverence Farms utilizes grazing, line breeding and nursing herd

24. Raising the cull line to match the falling milk price

24. Raising the cull line to match the falling milk price

Published: March 1, 2018 Extra enewsletter

Pennsylvania dairy consultant Jim VanDerlinde encouraged dairy producers to think a step beyond the milk-to-feed ratio to determine how long a cow to be culled remains in the milking herd. Instead, he says to factor in the exiting cow’s replacement cost too.

Pennsylvania dairy consultant Jim VanDerlinde encouraged dairy producers to think a step beyond the milk-to-feed ratio to determine how long a cow to be culled remains in the milking herd. Instead, he says to factor in the exiting cow’s replacement cost too.

Add the feed cost per cow to the feed cost per replacement heifer and compare it against your current milk price to determine how much milk the cow has to make before she is culled.

Q. What feedback have you received from producers about this way to approach culling?

“This post had a pretty impressive response all the way around. I received phone calls, emails and texts both from people I knew and people I had never met before. How many times have you read something that made you stop and hunt down the author? That doesn’t happen much.

This post also sent a ton of traffic to the Dairyhack website. A total of 87 people joined my weekly email list after this article was posted in the first 24 hours. That’s an impressive response. Most people thanked me for my no-nonsense, fact-based writing style.

“My favorite response was from a smaller tiestall herd owner who said this, ‘Every stall has to produce a minimum of 50 pounds to keep the doors open. Your post early on showed me I need to keep things tight. I now cull if a cow doesn’t peak at 100 pounds.

The data here says they just aren’t profitable on the lactation curve. I’m lucky to have a guy locally that has a market for 3-year-old dry cows, so I toss anybody new that hits below the mark. I breed them back and send them down the road two months off.

No exceptions. My herd has made some pretty astounding jumps as a result. Three years ago, I had a herd of high-type fancy cows that averaged 16,000 pounds. Now I’m looking at 26,000 pounds with a BAA 6 points lower.’

“Helping people improve their farms is just awesome.”

PHOTO: Holtein cows. Staff photo.

—Jim VanDerlinde, consultant, Dairyhack

Read the article: Raising the cull line to match the falling milk price

25. Beef-on-dairy done right: How to make the crossbred calf the market desires

Published: July 1, 2018 print issue

With more and more dairies breeding to beef semen as a means to add value to male offspring and control heifer inventory, they are finding themselves looking at little black calves and sometimes wondering what should they do next.

Tom Peters, a consulting nutritionist and partner in Central Sands Dairy in Wisconsin, warns dairy producers, “don’t screw this up” by creating a black Holstein that’s not genetically capable of performing in the competitive feedlot environment. Ray Melanderm, Purina beef production specialist, further noted the importance of neonatal calf care in setting up the animal to meet yard expectations for growth and gains.

Q. For dairies with their first crop of black calves hitting the ground, what advice do you offer for capturing the highest dollar value in the marketplace?

“As with the beef industry, quality genetics matters for sire used. Thus, dairy producers should make proper selection and proper planning on which bulls to use for sires before they get going on this crossbreeding program. After the fact is just not a sensible move. Again, just because the calves are ‘black’ does not make value of them higher.

“Many packers have already called me and discussed the failures of cattle (crossbreds) they are seeing show up in feedlots. I have had two packers tell me they ‘want to find out where our calves are going to be fed, and then they will look at them.’

If people think they have great-quality crossbreds, then they might just retain ownership of the calves and finish them. However, this is a long delay in money returns and is dependent on the feedlot they are finished in.

“There is no easy way to maximize returns on these calves that will substitute for superior-genetic animals (bull stock).”

—Tom Peters, Ph.D., consulting nutritionist and partner in Central Sands Dairy, Wisconsin

“The crossbred program continues to gain in popularity. For those dairymen who marketed calves this fall, prices were running 100 to 150 dollars more per calf than traditional Holstein bull calves. Crossbred heifers were more in the plus-100-dollar range.

At Heartland Cooperative, we introduced a calf program called Outlook. Following a neonatal calf program which includes prescribed amounts of IgGs of colostrum, dipping navels and a feeding program for the farm, they are able to tag the calves with pink eartags to notify the buyers these calves have had extra care at birth.”

PHOTO 1: Treat calves destined for the beef market with the same quality of care as a replacement heifer calf. “If a calf has the opportunity to be a high-quality steer in the feedyard, it begins in the first four hours of life,” says Ray Melander, a Purina beef production specialist. “If someone messes that up, that calf is compromised for the rest of its life.” Photos courtesy of ABS Global.

—Ray Melander, Purina beef production specialist ![]()

Read the article: Beef-on-dairy done right: How to make the crossbred calf the market desires