The Progressive Publishing team is pleased to once again bring you the Top 25 most well-read articles of the year. This list reflects content published from Oct. 1, 2016, through Oct. 1, 2017, and is based on Google Analytics.

When possible, our team asked follow-up questions from the authors and dairy producers featured.

1. Kentucky farm widow spent 30 years dairy farming solo

Readers met Betty Rose Young Elliott in this December 2016 online article that was also featured in our March 2017 print issue. Following the death of her husband in 1966, Betty – then 41 – continued to run the farm and raise five children.

Her story touched many, including fellow farm widow Amanda Peckins Leik ('Raising these calves saved me': The story of Michigan dairy widow Amanda Leik). Both articles were written by Betty’s daughter-in-law, Karena Elliott.

Q. Why do you think this piece resonated with readers?

“It’s truly an underdog story of success,” replies Betty’s grandson, Clay Elliott. “Granny was set up for failure, but she was able to prove everyone wrong. She did everything right for her family and the farm despite all of the challenges she had to face. She helped people along the way and made the world a better place.” Clay is a senior at the University of Louisville and will attend law school next year.

“I think the piece resonated with readers because many females in farming have experienced these difficulties in one way or the other,” explains her daughter Cindy Elliott O’Daniel of Paducah, Kentucky.

Real life rarely includes “happily ever after.” People disappoint us, accidents happen, and tragedies knock us to our knees. Readers could easily picture their mother, neighbor or family friend facing Betty Rose’s circumstances. And we all hope we would have the courage to face adversity and win.

Q. What do you think Betty would have said about all of the online readers and comments they shared?

“She would have liked the comments being instant and not having to wait until the next issue for updates,” shares Cindy. “She would have also enjoyed not having to walk to the mailbox. She was the first person anyone in our family knew who personally got a desktop computer for home use.”

Everyone thinks they are “normal.” It’s hard for most people to view their own lives as extraordinary. As a woman of few words, Betty Rose would have simply replied she just played the hand she was dealt one day at a time.

I also like to think she would have reached out to women like Amanda Peckins Leik with a word of encouragement from someone who could say, “I know how you feel. I’ve been there. You can do it. You’re stronger than you think.”

PHOTO: Betty Rose Elliott of Paducah, Kentucky, dairy farmed solo for 30 years following the death of her husband in 1966. Photo courtesy of the Elliott family.

—Karena Elliott, Texas freelance writer

Read Kentucky farm widow spent 30 years dairy farming solo.

2. Hoekstras happy with 28,000-pound crossbred herd

Seventeen years ago, Hoekstra Dairy in Oakdale, California, began crossing their purebred Holsteins. Today, the 2,800-cow herd is comprised of a strategic stacking of Montbeliarde and Swedish Red genetics with Holstein. They are pleased with the resulting cows, which are strong producers with fewer health events.

Seventeen years ago, Hoekstra Dairy in Oakdale, California, began crossing their purebred Holsteins. Today, the 2,800-cow herd is comprised of a strategic stacking of Montbeliarde and Swedish Red genetics with Holstein. They are pleased with the resulting cows, which are strong producers with fewer health events.

Q. In your eyes, have you achieved the goal you had in mind for breeding a cow with the strength and functional traits you desired?

These cows are heavier than a Holstein and not any taller. The Montbeliarde brought width back into them; that was one thing we really wanted, to open the chest width between the front legs more. As far as stature, we had a lot of variation at first due to Jersey in bloodlines, but we now have a more uniform herd.

I can see it when I look over the lockups. The biggest thing is: These cows are wider and thicker. People have issues with seeing extra body condition on a cow and think transition issues (retained placenta, milk fever, displaced abomasum), but we only have a milk fever once every two months, and we’ve had two DAs in the last three-and-a-half years.

They are staying in the herd longer, and we are getting more lactations out of them. I think we’ve made huge strides. I’m very happy with the conformation, structure, width and strength. Those were the biggest improvements we’ve seen.

PHOTO: Hoekstras found success with a three-breed cross – Swedish Red, Montbeliarde and Holstein – over the past 20 years. Photo provided by Ami Avila, Creative Genetics.

—Kurt Hoekstra, Hoekstra Dairy and Crossview Dairy, Oakdale, California

Read the full story: Hoekstras happy with 28,000-pound crossbred herd

3. New drive-over commodity delivery bridge a first in the U.S.

TLK Dairy in Mountain Home, Idaho, welcomed more than 800 visitors this summer to see its first-in-the-nation indoor feed mixing center which featured a drive-over commodity delivery bridge. It was the cover story of our Oct. 1, 2017 print issue. The facility mixes more than 820 tons of feed per day for 17,500 dairy animals on-site.

PHOTO: Pictured is the first-in-the-nation drive-over commodity unloading bridge inside an enclosed feed mixing center at a dairy. Photo by Ray Merritt.

Read the full story: New drive-over commodity delivery gridge a first in the U.S.

4. Milk with no home: Producers, processor face challenging times

Please note that this is not the actual letter sent out by Grassland Dairy Inc.

What started out as a year of milk price optimism turned into a nightmare for some dairy farmers when Grassland Dairy Inc., based in Greenwood, Wisconsin, sent letters to several dozen patrons notifying them the company would no longer be able to accept their milk, effective May 1.

The situation became a lightning rod, reaching all the way to North American Free Trade Agreement (NAFTA) renegotiations.

Q. It’s been nearly nine months since the Grassland situation revealed milk supply/demand imbalances in the U.S. and escalated an international trade war of words between the U.S. and Canada. What’s the situation today?

Although nearly all affected dairy farmers found a market for their milk, the situation raised awareness of how strong milk production gains had stretched processing capacity in Wisconsin and beyond. Since then, excess milk production has led to cooperatives exploring and implementing base production programs, less competitiveness among processors and a decline in the milk price premium structure.

It also raised the level of discord over Canadian dairy policies long criticized by U.S. dairy industry leaders. As NAFTA renegotiations between the U.S., Canada and Mexico got underway this fall, the U.S. was demanding an end to what it terms “protectionist” policies that close U.S. export markets, including Canada’s supply management program.

Canada, in turn, was entrenched in its efforts to protect its domestic dairy farmers from a flood of U.S. dairy ingredients and products. Stay tuned.

ILLUSTRATION: Illustration by Corey Lewis.

—Progressive Dairyman Editor Dave Natzke

Read the full article: Milk with no home: Producers, processor face challenging times

5. The calf that found cancer

Oklahoma dairy farmer Anita van der Laan discovered she had breast cancer thanks to a head butt from Gemma, a sweet-eyed Brown Swiss calf. Progressive Publishing associate editor Carrie Veselka came across this story in a blog post from Dairy MAX and says it was a uniquely special experience to visit with van der Laan and tell her story.

Q. How have you continued Gemma’s legacy?

We’ve continued Gemma’s legacy by giving her sisters names that begin with “G:” Gloria, meaning “glory to God,” Gertrude, also meaning “glory to God” and the newest arrival, Gretje, meaning “pearl of God.” It’s hard to find a “G” name that has a meaning and takes after our angel. I hope my story made a difference to somebody, even if it was just one person.

—Anita van der Laan, Oklahoma dairy farmer

Read the article: The calf that found cancer

6. 5 things top dairies do to get cows bred

Attaining conception rates over 40 percent and pregnancy rates over 30 percent is happening among the most reproductively efficient herds out there.

Herds hitting this high mark have a few things in common: excellent dry, pre-fresh and post-fresh cow programs; voluntary waiting periods extended to 70 to 80 days in milk; consistent heat detection and compliance to synchronized breeding programs; cow comfort and cooling; and high-quality nutrition.

Q. If you could add a sixth item to this list of things top dairies do to get cows bred, what would it be?

We have been facing unusually hot summers around the U.S. in recent years. There is no way to reduce the negative effects of heat stress on dairy cow performance without applying housing interventions. Actions for heat abatement include shade to block direct solar radiation, water spraying to increase conductive heat loss, and ventilation to improve convection for enhanced evaporative cooling.

Ideally, a combination of all these methods should be used. However, that does not mean that if the producer cannot implement all three changes or, even better, build a new cross-ventilated barn, he should not implement any of those interventions. Even with old installations, there are successful dairies that have been increasingly implementing different methods for different categories of animals to reduce heat stress.

What they do is just continue to add more fans in some specific pens, as in the milk cows’ pen, to have a financial return that permits taking additional steps to mitigate heat stress. These steps could include adding more shade for the dry cows in an open lot or adding water sprinklers in the holding area. Implementing changes for heat abatement, even slowly, is much better than not taking any action at all and hoping that a change in the weather will enhance the dairy’s profits.

—Anibal Ballarotti, ABS Global Technical Services Consultant

Read the story: 5 things top dairies do to get cows bred

7. Matsches maximize efficiency with new rotary milking parlor

In the summer of 2016, the Matsche family began milking cows in a brand new 80-stall rotary parlor. With the goal of milking 5,000 cows between two sites, they sought to make this new facility as efficient as possible by incorporating technologies like automated crowd gates and footbaths.

Q. Now well over a year into the new parlor and facilities, what have been some of the greatest challenges you faced and how have you worked to overcome them?

“We’ve got milk!” states the picture of owner Scott Matsche as you walk up the stairs to the loft of the milking parlor to view the 80-stall rotary. The dream of building a dairy to support the families involved came true. Our children and God keep us inspired for the future. Some challenges we have faced in the past year since the first cow stepped on the rotary:

- Heifer housing improvements and expansion

- Ensuring training on milk harvest, animal care and maintenance is maintained

- A tour plan for all visitors to educate them on where food comes from

- Providing a safe environment for our community, employees, family and cows

Those are just some of the key factors we as a family face as we gear up for the future in the world of dairy. Working hard, teamwork and communication every day keep the farm running. We have a great workforce who we are thankful for and who help get us through all these challenges to keep Papa Scott saying, “We’ve got milk!”

PHOTO: With eight glass overhead doors, natural lighting fills the milking parlor at Matsche Farms. Photo provided by Lori Kuhn-Weishoff.

—The Matsche family, Matsche Farms Inc., Birnamwood, Wisconsin

Read the full story: Matsches maximize efficiency with new rotary milking parlor

8. Nutrition profile for a high-performing Wisconsin herd

Every decision made on Doug Syryczuk’s Wisconsin dairy is tested against three factors – and those factors aren’t “cost, efficiency and profitability.” Instead, the measures are: consistency, comfort and calm. That simple business model has resulted in a herd averaging 95 pounds with a somatic cell count of 90,000.

Currently, Syryczuk is feeding about 122 pounds of as-fed feeds – about 56 percent dry matter – around 58 pounds per day of corn silage, 25 pounds per day of alfalfa haylage, 8 pounds of oatlage and 32 to 33 pounds of mixed feed that includes protein and ground dry corn.

PHOTO: Doug Syryczuk feeds about 122 pounds of as-fed feeds, including corn silage, alfalfa haylage, oatlage and mixed feed. Photo by Mary Hookham.

Read: Nutrition profile for a high-performing Wisconsin herd

9. Klein Farms cuts out middleman by selling directly to consumers

Klein Farms was one of three Pennsylvania operations we featured in our June 2017 issue for their on-farm processing methods. The Kleins sell raw milk and cheese, and just added an on-farm ice cream parlor. The dairy sells 1,400 gallons per week retail and wholesales another 500 gallons.

Q: What’s new for 2018?

With the construction of a small pavilion added to the existing playground area, visitors have been staying longer and enjoying the visit - and potentially making additional purchases, such as the sMOOgurt yogurt smoothies - while watching the children play.

For the upcoming year, a few more playground improvements are planned, including a new piece of equipment and improved lighting. Moving forward, the addition of milkshakes and sundaes to the ice cream parlor offers a lot of potential to grow the business.

PHOTO: The Kleins began their adventure with direct marketing with a raw milk license, some cheese-making skills and a small on-farm store. Pictured is Lori, cheesemaker at the farm. Photo courtesy of Klein Farms.

—Beth Klein, Klein Farms, via freelance writer Tammy Scully

Read the article: Klein Farms cuts out middleman by selling directly to consumers

10. Neighborhood pitches in to help injured farmer harvest crops

After a freak accident at World Dairy Expo 2016, Mike Halpin’s friends and neighbors banded together to help bring in the harvest on his family farm in Pontiac, Illinois. This story, which was featured in our series of inspirational stories in our March 2017 issue, embodies the spirit of “love thy neighbor” that makes farming such an amazing profession.

Q: How is Mike Halpin recovering?

According to Mike’s uncle, Bill Halpin, he spent eight months in hospitals and rehab but is now able to get around in an electric wheelchair. “Recuperation has been slow, but the fight’s not over yet,” Halpin says.

PHOTO: A grain cart unloading corn at Crescent City Farm. Photo provided by Roger Birch.

Read the article: Neighborhood pitches in to help injured farmer harvest crops

11. Best on-farm fix: Peters prevents calf scours with apple cider vinegar

Pennsylvania dairy farmer Jessica Peters found a tablespoon of apple cider vinegar fed twice daily dramatically improved her Jersey calves’ ability to rebound from scours caused by E. coli. Both the duration and severity of the disease was reduced. This simple household product has replaced pharmaceutical preventative drugs at Spruce Row Farm.

Pennsylvania dairy farmer Jessica Peters found a tablespoon of apple cider vinegar fed twice daily dramatically improved her Jersey calves’ ability to rebound from scours caused by E. coli. Both the duration and severity of the disease was reduced. This simple household product has replaced pharmaceutical preventative drugs at Spruce Row Farm.

Q. Since the time this article was written, have you continued to use apple cider vinegar for scouring calves? What other remedies have been successful in helping you raise healthy calves on your dairy?

Yes! We’ve been using the vinegar for over a year now. For the first few months, the apple cider vinegar seemed to end scours completely. Since then, it hasn’t completely eradicated scours but has made them less frequent and much more manageable.

Calves don’t get as sick for as long and, when they do, treatment is mostly banamine and electrolytes. Since we began the vinegar, we’re able to raise stronger calves more cost-effectively.

Other than the typical calf management ideals, the apple cider vinegar has been our best calf hack. There’s also a lot to be said for consistency in your routine and the people who feed the calves. We’ve always been big advocates of knowing your animals to better care for your animals.

PHOTO: Jessica Peters says it was pretty easy to try this fix. “We bought a gallon of apple cider vinegar, borrowed a tablespoon from the house and bought a little squeeze bottle to pour it out of,” she explains. Photo by Jessica Peters.

—Jessica Peters, Spruce Row Farm, Meadville, Pennsylvania

Read the full article: Best on-farm fix: Peters prevents calf scours with apple cider vinegar

12. Harnessing the power of hybrid vigor

When done strategically, crossbreeding can improve health, fertility and overall profitability in just one generation because hybrid vigor boosts production by 2 to 5 percent and fertility and health by 10 to 15 percent over the parent average. To garner these gains, dairy producers must invest in bulls among the top genetics in their respective breeds with the highest parent averages.

Q: What has been the response by your customers to the concept of capturing hybrid vigor through crossbreeding?

Current customers recognize the benefits of a properly designed crossing program in their day-to-day routine with healthier cows and higher components. New customers will be able to see similar results literally as soon as their first generation freshens.

Regional differences in benefits exist from milk market variations and other economic circumstances. Herds will see the most income boost where milk value is almost exclusively in fat, protein and solids-not-fat fractions. However, herds in all circumstances benefit from easier management and reduced production costs. Reduced costs come from better fertility and herd health, as well as reduced feed costs from a moderate cow size.

Herds desiring easily managed cows capitalize on the benefits of a properly designed crossing program. The ease of management turns into higher net income for those who focus on efficient production systems.

Grazing herds and low-cost production systems also benefit greatly from the program due to tremendous fertility and health advantages. Block or seasonal calving and 12-month calving intervals are readily achievable with limited reproductive interventions when using a properly designed crossing program.

PHOTO: These second-lactation cows are the daughters of Norwegian Red sires crossed with Jersey-Holstein dams. This three-way cross offers advantages in traits like health and fertility. Photo provided by ABS Global.

—Gary Rogers, Ph.D, ABS Global, Global technical adviser

Read the full article: Harnessing the power of hybrid vigor

13. Computer vision technology tested on California dairy

Cainthus, a global computer vision technology company, recently installed 40 cameras in a pen of 400 Holstein cows on Maddox Dairy in Riverdale, California. Each camera captures 30 images of the pen per second and then software collects and analyzes the images for individual cows’ activity to monitor cows’ feed and water intake.

Q: What new developments have occurred with your computer vision technology since early 2017? Has the system been installed on any more dairies?

Since we last spoke, we have done more installs in the U.S., as well as in Italy and Spain. We recently reached agreements to do an install in one of the leading U.S. ag schools, as well as some pioneering initiatives in China. Our biggest problem is currently executing install orders in a timely fashion – a nice position for any company.

Regarding development, most of the team’s focus has been on making the system more alert-focused rather than expecting farmers to interpret data flows. This is to enable Alex (our system’s name) to be more of a farmer’s assistant rather than a data discovery portal. Looking forward to more strong growth in 2018.

PHOTO: A live video image capable of tracking how long each cow was eating caught the attention of Maddox Dairy last year. The dairy has since installed the first commercial test of computer vision technology on a livestock farm. Illustration by Kristen Phillips.

—David Hunt, co-founder, Cainthus

Read the full article: Computer vision technology tested on California dairy

14. Timing of insemination: Achieve optimal conception by working the averages

Penn State Extension educator Andrew Sandeen says years of research indicate, on average, a cow has the best opportunity to become pregnant when A.I. is performed 12 to 24 hours before ovulation occurs or four to 16 hours after the onset of standing heat. However, when in doubt, it is better to inseminate early than late.

Q. Regarding timing of insemination, what advice do you offer to dairy producers using activity monitoring systems to aid in identifying estrus?

For optimum conception rates, it is beneficial to establish at least two times of the day when A.I. can be performed. Activity monitoring systems provide some very specific information, but the benefits are limited to what management is able or willing to do. If A.I. is only performed at one particular time of day in a herd, there may be lost potential.

As far as what the ideal timing should be, aim for four to 16 hours after the time when an activity threshold is crossed. If there is an intense desire to manage the details, first-lactation cows can be inseminated a little bit later (four to 16 hours after crossing the activity threshold) than older cows (zero to 12 hours after crossing the activity threshold), based on results from an activity monitoring study.

But in many situations, managing these different age groups separately is more complicated than it is worth.

Finally, it is better to err on the side of inseminating too early rather than too late. Ovulated oocytes can’t hang around too long, waiting for those sperm cells to arrive.

ILLUSTRATION: Staff illustration.

—Andrew Sandeen, Penn State Extension educator

Read the full article: Timing of insemination: Achieve optimal conception by working the averages

15. How to prevent and treat abomasal bloat in young calves

Abomasal bloat is a syndrome that occurs in calves at 1 to 2 weeks old and, more often than not, results in death. With cases of abomasal bloat on the rise, this article is helpful in identifying its symptoms and causes as well as offering suggestions for prevention and treatment.

Author Progressive Dairyman Editor Karen Lee says, “I found this to be useful information as I raise bull calves from birth to 300 pounds and experienced the loss of some of them to bloat. When I saw other people asking about how to prevent and treat calves with bloat on social media, I knew this information would be helpful to others as well.”

Q: Has there been any research released in the past year to help identify better feeding recommendations or risk factors that could potentially impact the prevalence of abomasal bloat?

There really hasn’t been any new research published on how to better prevent abomasal bloat. However, clinically, we have come up with feeding recommendations that largely seem to be successful in minimizing the occurrence of bloat. The first is to make sure producers are feeding milk or milk replacers with a total solids in the 13 to 15 percent range.

This is best done by using a Brix refractometer on a regular basis to estimate the total solids the calf is being fed, which allows us to predict the osmolality or “concentration” of the milk. Secondly, we want to make sure milk replacer mixing is consistent. Again, I recommend using a Brix refractometer to check the total solids from the first calf, middle calf and last calf fed.

If the Brix value varies by more than 1 percent, we need to do a better job of mixing. Keeping consistent feeding schedules, feeding warm milk and always offering clean water to calves are also critical to avoiding bloat.

—Geof Smith, DVM, North Carolina University

Read the full article: How to prevent and treat abomasal bloat in young calves

16. Two Indiana calf operations focus on six key management areas for calf health

To optimize calf health, producers must focus on six key areas: colostrum, nutrition, bedding, air quality, sanitation and vaccinations.

In this article, panelists Brian Houin, Homestead Dairy LLC in Plymouth, Indiana, and Wes Obert, Legacy Dairy in Fort Branch, Indiana discussed how they use auto-feeders, air tube ventilation and an all-in, all-out system to hone in on these six key areas and create an environment where calves can thrive.

An online follow-up question was asked:

Q. At what age (in weeks) do you wean? What is your calf pellet consumption, and what is the average daily growth of the heifers?

We are feeding the 40 Fit program and allow the calves unlimited milk for the first 30 days, then we drop down to 10 liters over the next five days, and we hold this amount for seven days; over the next 14 days, we drop from 10 liters to 2 liters of the milk, and the calves are finally weaned at 70 days.

We push the milk to the calves, so we do not see much feed consumption until we hit that weaning stage, and it is amazing to see how fast the calves get up to 10 pounds of feed per day when we drop the milk down to 2 liters per day.

—Brian Houin, Homestead Dairy LLC in Plymouth, Indiana

We wean our calves a little later; we begin at 6 weeks, and they are off milk at 7. We move them out at 8 weeks. On the auto-feeder, we are not completely sure.

On the individual pens, we begin weaning when we see feed consumption at 2 pounds per day for three days straight, and that is typically at about 6 weeks, maybe a little earlier. We drop the milk feeding down and allow the calves to get used to not receiving any milk and then move them. Typically all of our calves are completely weaned at 8 weeks.

—Wes Obert, Legacy Dairy in Fort Branch, Indiana

PHOTO: Participants of the calf feeding panel discussion at the Indiana Dairy Forum were Brian Houin, left, and Wes Obert, right. Photo by Somula Schwoeppe.

Read the full article: Two Indiana calf operations focus on six key management areas for calf health

17. Genetic mutation from one bull caused loss of 500,000 calves

Genomic research confirmed Pawnee Farm Arlinda Chief, a Holstein bull heavily used in the 1960s, carried a haplotype (HH1) linked to increased stillbirths and decreased conception rates. While this prolific sire is estimated to have contributed $30 billion to increased milk production, his genetics may have influenced the death of half a million offspring.

Q. In addition to this industry-changing information on Pawnee Farm Arlinda Chief, what other major findings are you discovering (or research are you conducting) related to dairy cattle genetics?

Many dairy producers now improve their selection, breeding, mating and management decisions by genotyping young calves because just one DNA sample can predict many traits across the animal’s lifetime. During the last year, new genomic predictions for cow death loss (livability) and gestation length were added, and predictions for six cow health conditions (mastitis, metritis, retained placenta, ketosis, milk fever and displaced abomasum) and feed intake have been developed with much help from university researchers.

Predictions for several other traits are possible in future years. Initial genomic research focused on increasing the reliability of predictions within breeds, and more recent research will also provide accurate genomic predictions for crossbreds. To reduce harmful effects of inbreeding, many producers now use genomic mating programs.

As with the discovery of the fertility loss mutation in Chief descendants, research is continuing to discover which DNA alleles affect which traits so genomic tests are more direct and accurate for more animals. Most of the 2.6 billion letters of DNA in each animal’s chromosomes are not yet understood, but we are making progress.

PHOTO: Widely used Holstein bull Pawnee Farm Arlinda Chief made a mark on the breed by transmitting desirable traits like milk production, but it was discovered last year that he also passed on an undesirable trait that caused thousands of stillbirths and abortions. Photo provided by Danny Weaver and Agri-Graphics Ltd.

—Paul VanRaden, USDA Agriculture Research Service Animal Genomic and Improvement Laboratory

Read the full article: Genetic mutatin from one bull caused loss of 500,000 calves

18. Kansas farmer loses both legs in accident, still farming two years later

Three years ago, Zach Short was electrocuted in a farming accident that left him with both legs amputated, a seriously damaged left arm and severe burns covering his entire body. Today he is back in the tractor and working on his family farm, thanks to the continued prayers and support of family and friends.

“This story has gone further than I ever expected,” says author Carrie Veselka, an associate editor for Progressive Publishing. “I received several calls and emails from readers who were so inspired by Zach’s experience they discussed it in church and shared the story with their friends and neighbors.

Zach’s story was also aired on CBN’s The 700 Club on Sept. 8, 2017. Zach and Jodi welcomed their second child, Brycen Zachary Short, on November 9.”

PHOTO: Zach Short says one of the biggest blessings from being able to save his left arm is that he is still able to work and able to hold and carry his daughter. Photo provided by Zach and Jodi Short.

Read the article: Kansas farmer loses both legs in accident, still farming two years later

19. Dairy Strong Bloggers: I gave up a great job for more hours and no benefits

After spending three years working as a dairy nutritionist, Christine Bender traded in the perks of corporate employment for the opportunity to return to her family’s dairy as the sixth generation. She is now applying what she learned about nutrition and management in the field to her growing responsibilities on the farm.

Q. Since returning to the family dairy farm, how has your role evolved in the past year?

Every day is a new challenge. My role has evolved greatly in the last year, and I’m about to undergo another change. When I returned to the family farm a year ago, I became the calf and heifer manager, as I felt very strong in that area. I took time to learn the current routine, and I quickly started implementing changes to increase efficiency and performance.

We purchased a milk taxi and began feeding calves three times a day. We saw a 50 percent increase in weaning weights at 8 weeks old. Next, I jumped into human resources and held annual reviews for the first time ever with the help of my parents.

A few months later, I began holding milker meetings to help make employees aware of upcoming changes; these meetings are held as needed. I quickly learned managing animals is easy compared to managing people. It was a busy summer, to say the least, with building a new transition cow barn, lagoon and remodeling our original freestall barn. In the coming weeks, I will once again be changing roles, becoming the overall herd manager.

PHOTO: Left to right: Christine Bender and her parents, Cindy and Peter McFarland, farm in Watertown, Wisconsin. Photo provided by Christine Bender.

—Christine Bender, McFarlandale Dairy, Watertown, Wisconsin

Read the article: Dairy Strong Bloggers: I gave up a great job for more hours and no benefits

20. Why don’t cows get pregnant?

When a cow struggles to get bred, there are a few key areas to troubleshoot. Is she in good health? Did she ovulate? Did she settle, but then lose the pregnancy? And was she inseminated correctly with high-quality semen?

Exploring and answering these questions can help dairy producers determine what may be hindering reproductive performance.

Q. What criteria should a dairy producer consider during semen selection to improve the chance of a successful pregnancy?

Reputable A.I. organizations provide a lot of valuable information and aim to provide consistent, high-quality doses of semen, providing good opportunity for fertilization success. But there are certainly differences between individual bulls – and even differences in quality between different batches.

To understand which bulls tend toward better fertility success, one can compare measures for Sire Conception Rate and an assortment of other sire fertility estimates and rankings.

There are a variety of programs and lists routinely developed for the purpose of identifying superior sires and semen with the highest quality and chance for success. Average conception rates can vary by a few percentage points between different sires.

What one must be most careful of is when using semen acquired from a less reputable A.I. organization. Care must be taken to avoid over-investing in semen that may or may not have been processed up to the same standards as the more reputable organizations. Also, one must be diligent to ensure semen has been handled appropriately at all times. Even with the highest-quality semen, if it was mishandled at any point, fertility may be compromised.

ILLUSTRATION: Illustration by Kristen Phillips.

—Andrew Sandeen, Penn State Extension educator

Read the article: Why don’t cows get pregnant?

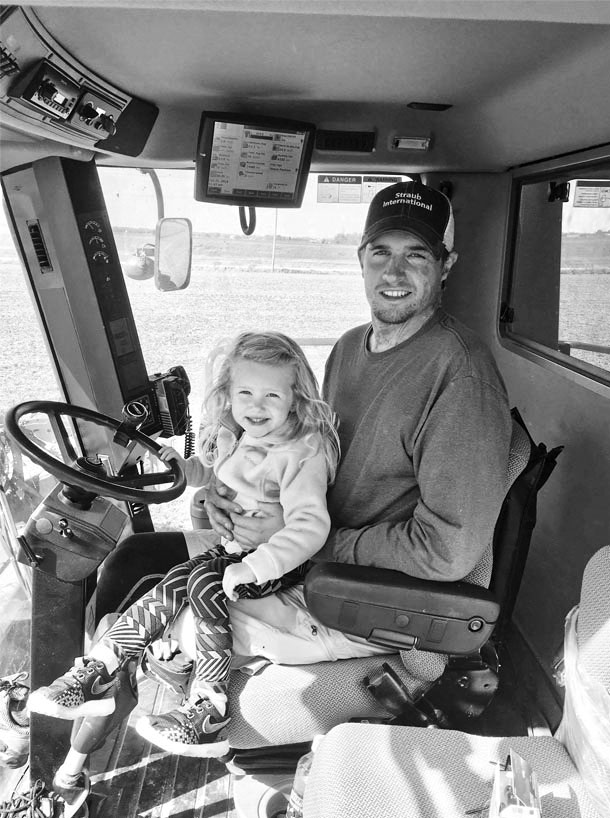

21. Sunrise Dairy starts from scratch, grows to 300 cows in three years

This story lead came from a Facebook message with a photo of a little boy reading our magazine on his father’s knee and grew to so much more. Kris Fry started Sunrise Dairy with nothing more than a few empty barns in bad condition. Jump to three years later, and he has shipshape barns and 300 cows.

It has been a tough year for Fry’s operation. Due to low margins, he sold off half his herd to get back to profitability and has taken part-time work off the farm, but he is holding out for better times ahead. “I’m hoping for a better 2018, and I think it’s coming,” Fry says.

PHOTO: Sunrise Dairy in Harbor Beach, Michigan, began with a few empty, run-down buildings. Three years later, the herd is up to 300. Photo provided by Kris Fry.

Read the article: Sunrise dairy starts from scratch, grows to 300 cows in three years

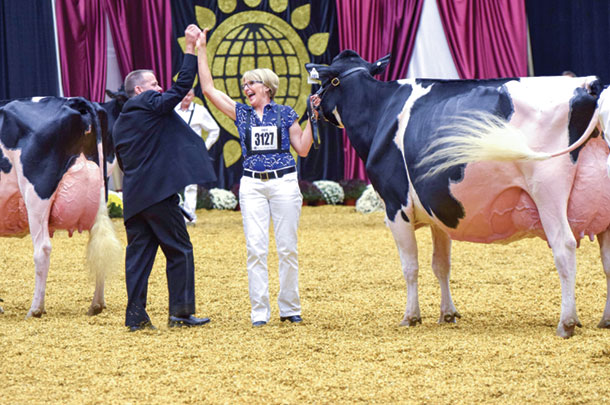

22. Underdog WDE champion shows dreams really do come true

This 2016 article featured Sheeknoll Durham Arrow’s rise to become last year’s World Dairy Expo Reserve Grand Champion Holstein. The cow known as “Thomas” by friends and family got her nickname when she was shown as a calf by the Sheehans’ 5-year-old nephew, who had a fascination with Thomas the Train and a dislike for the name “Arrow.”

The Sheehan family was surprised to see photos of Jeanette Sheehan and Thomas everywhere at the 2017 expo – especially a big wall hanging in front of the stadium of Jeanette’s now-iconic handclasp with the judge.

Thomas has adjusted to her celebrity status quite easily but, according to Jeanette, has turned into a bit of a diva. “Some cows can be needy, but she’s not like that. She’s not a fan of pampering; she just does her own thing. She has her own little personality, that’s for sure.” Thomas is expecting another calf in April 2018.

PHOTO: Jeanette Sheehan calls high-fiving the judge “the most awesome moment ever.” Photo provided by Laura Wackershauser.

Read the article: Underdog WDE champion shows dreams really do come true

23. Is your hoof trimming program preventing lameness?

In some cases, a herd’s lameness problems are worsened by an unskilled hoof trimmer. In fact, trimming too much hoof horn can cause more issues than not trimming enough, particularly for cows in high-wear environments like confinement.

Q. What are the goals of a good hoof trimming protocol? And what are the consequences of improper trimming?

Not all trimming is beneficial to the cow! Good trimming restores a more upright claw angle and distributes weight evenly between the inner and outer claws of the foot, but poor trimming can be the cause of a lameness problem.

It is very important to identify when the trimming occurring on the farm is part of the solution to lameness or part of the problem. This article details the key mistakes made by trimmers related to overtrimming or undertrimming the claw.

—Dr. Nigel Cook, veterinarian, University of Wisconsin – Madison’s School of Veterinary Medicine

Read the article: Is your hoof trimming program preventing lameness?

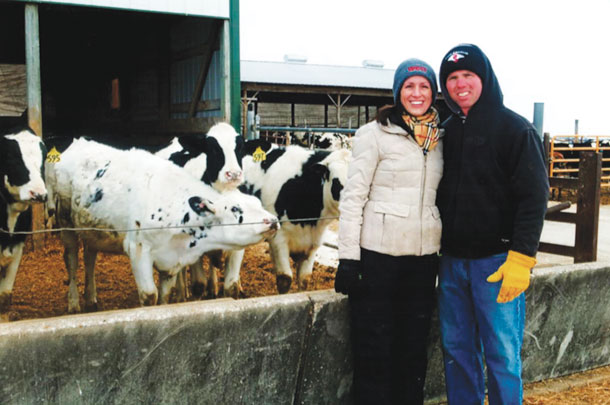

24. Young couple breaks into the dairy industry

Neither Nick nor Maria Woldt grew up on a dairy, but they had a dream to join the industry and worked hard to make it come true. Woldt worked his way up to a quality herd of 55 Holsteins through a unique partnership with Roger and Becky Weisensel, an older couple who wanted to start transitioning out of the dairy industry.

The Woldts were recently accepted to join a new dairy co-op that caters to small artisan cheesemakers who need high-quality milk for their products. “Low cell count has always been our claim to fame, so we are happy to join a new co-op that can give us a little more money for our milk,” Maria says.

They also stay busy learning how to balance Nick running the dairy, Maria working for Wisconsin’s Dairy Business Association and raising their daughter Lexington, who joined the family in 2017.

PHOTO: Nick and Maria Woldt operate a 55-cow dairy, and Maria also works as the industry relations director for the Dairy Business Association. Neither grew up on a dairy, but both found their true calling in the industry. Photo provided by Nick and Maria Woldt.

Read the article: Young couple breaks into the dairy industry

25. Crawley dairy shares secrets to keeping calves healthy

The Crawleys know keeping calves healthy is an essential component of any successful youngstock program. To accomplish this, they not only feed calves probiotics and 1 gallon of high-quality colostrum at birth, they also feed the calf its mother’s milk for feedings two through four.

This, combined with the Crawleys’ meticulous protocols for cleaning and checking for sick calves, means they only lose one or two calves every year and have greatly decreased the prevalence of scours in their calf program.

PHOTO: Tim and Nikki Crawley farm in Gravette, Arkansas, on land that has been in Tim’s family since 1922. Photo by Jenna Hurty-Person.

Read the article: Crawley dairy shares secrets to keeping calves healthy ![]()