Editor’s note: The following article is the first in a series of articles from the author after a recent trip to observe China’s dairy industry. Click here to read the second of the two part series Chinese milk quality: A question mark may be appropriate.

The U.S. is the world’s top producer of cows’ milk, but it may be a bit of a surprise to know who rounds out the top three: India and China.

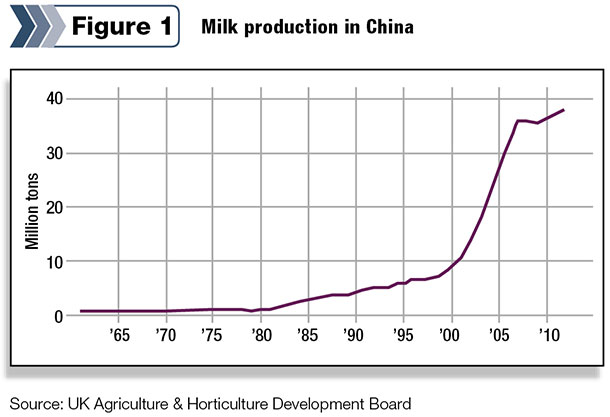

China’s milk production took off around the year 2000 (Figure 1). By 2007, they had more than quadrupled their milk production from 9,120 U.S. tons to 38,858 tons per year. But then came 2008, a pivotal point for dairy in China: the year of the melamine scandal.

It is reported that melamine, an industrial chemical, was added to substandard milk in order to artificially increase the protein content. It sickened tens of thousands of children and resulted in at least six deaths. China’s dairy industry stalled. Production was down sharply in 2008. Since then, production growth has been moderate, increasing about 3 to 6 percent per year. By 2014, production finally was back to the 2007 level.

I had the opportunity to be in China in October 2015 to speak at the China Dairy Conference hosted by the University of Minnesota College of Veterinary Medicine and the National Mastitis Council. The conference, in its second year, was held in Hohhot in Inner Mongolia.

It drew more than 500 participants and more than 70 exhibitors. Being in China for a week does not qualify me to speak authoritatively on the industry there, but it provided me some insight concerning China’s dairy industry, and data is available that helps to tell the story.

As a result of the melamine scandal, China’s government has taken a more active role in the dairy industry, encouraging the transition from small farms to large integrated operations owned by milk processors. The belief is that this will ensure food safety.

As recently as 2006, more than 80 percent of the milk produced in China was on farms with fewer than 10 cows. Around 2002, village milking centers were developed where owners of cows walked them to be milked.

I spoke with a young woman who worked for the conference organizing company; her aunt still had three cows she milked at a milking center.

Prior to this, agents would go door-to-door to buy milk. The melamine scandal was blamed on small producers, but information since that time has implicated the traders and processors who handled that milk.

However, the die was cast; China began pushing large integrated operations, forcing many small farms out of business. From 2008 to 2011, the amount of milk produced on farms with more than 1,000 cows increased from 9 percent to 16 percent of the milk produced nationally, while that produced on farms with fewer than four cows decreased by 11 percent.

Several conference speakers and I had the opportunity to tour a large farm that milks 4,500 cows, owned by one of the largest processors in the country. That milk company, and several other domestic companies, own and operate farms totaling 25,000 to 45,000 cows each.

In addition, foreign companies such as Fonterra and Nestlé own and operate farms in China as well as process and market the milk from them.

In some sense, setting up large-scale farms is easy. Thus, it is not unusual to find farms with more than 10,000 cows in parts of China. There are constraints to dairy farm growth, including forage production.

In 2014, China imported almost 800,000 tons of alfalfa from the U.S., enough to feed 10,000 pounds per year to 160,000 cows. Feeding the larger herds will take more forage and grain production or more imports.

However, as any dairy producer knows, managing the details is what makes or breaks a dairy farm of any size. In my estimation, that is the current Achilles heel of China’s dairy industry.

On the farm we visited, we saw cows in headlocks with no action being taken in the pen, leaving us to wonder how long they were locked up. The manager said only half-an-hour, but clearly it was much longer.

In addition, as we watched milking in the rotary parlor, we noticed little things that increased the risks of teat-end damage, poor milk letdown and insufficient time for complete milking.

Some of these details will be learned. Improvements will be made. Performance will improve as both herd managers and employees develop additional skills. China has great potential to continue to grow its dairy industry, but there is still the issue of ownership. It is an industry being built with dairy units that are part of a larger company.

The degree to which those companies are able to engage their employees will likely determine their success. Integrated dairy companies will need to put a priority on developing employees to foster personal “ownership” by managers and workers. Engaged employees who take ownership for animal care and milk quality are a key ingredient to success of dairies in any part of the world. PD

Phil Durst is a senior educator with Michigan State University Extension. Email Phil Durst

References omitted due to space but are available upon request. Click here to email an editor.

Click here to read the final article in the series "China's dairy market and future potential for global imports"