The main ration is heavy on corn silage, which is to the preference of Henry Verhoog, senior dairy specialist with Grand Valley Fortifiers Ltd., who works with the farm’s nutrition program.

“I like 60 to 65 percent corn silage in all milk cow rations when able,” Verhoog says.

The Reijnens “make top-quality forage and are top-notch farm managers,” he adds, which enables him to balance the ration for the highest level of forage they are comfortable feeding.

Verhoog is also a big proponent of using cob meal in the diets for aggressive freestall herds. Cob meal is produced using a snapper head on the forage harvester to create a “palatable, nice feed that goes in the bunk well,” he says.

The commodities he adds to the ration include soybean meal and distillers grains. The soybean meal is palatable, and the distillers grains provide a good source of fat and energy to balance the soybean meal.

Reijnen used to feed pellets, but as it grew to be too expensive, he switched to soybean meal.

He started feeding the distillers grains nearly two years ago at Verhoog’s suggestion to try that or brewers grains.

Reijnen says he is not a fan of the brewers grains because of the moisture, but he does like the consistency of the distillers grains, and his cows seem to like it too.

The distillers grains are stored in his commodity shed. When it is brought in, he pushes it up and levels the top. He says it does mold on top, but he just discards that portion.

Chopped straw is another preference of Verhoog’s, no matter what the length of the forage happens to be.

With milk production at 36 kilograms and upwards of 40 kilograms at times, Verhoog’s biggest concern with this herd is maintaining a fine line between pushing the cows to reach their full potential but not jeopardizing their health.

Reijnen is pleased with how well the ration is performing. “It’s all set up for good milk production for my cows, and they stay healthy,” he says.

The additional milking cow rations are modified for two fresh cow groups – a fresh 2-year-old group consisting of 30 heifers and a fresh mature cow group of 20 cows.

The 2-year-olds are fed the same base diet as all milking cows, along with 1 kilogram chopped straw, 1 kilogram of a transition dairy supplement and 0.17 kilograms of fat (88 percent palmitic acid) per cow per day.

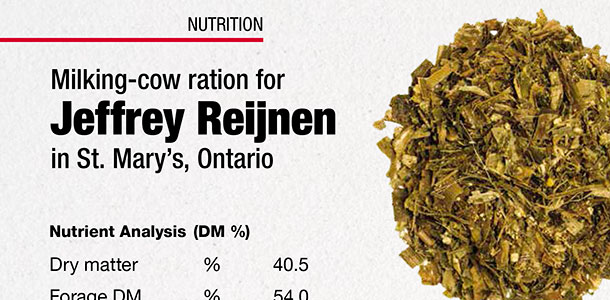

Click here or on the image above to view it at full size in a new window. (PDF, 531KB)

The fresh mature cows get the same ration as the fresh 2-year-olds with an additional 2 kilograms per cow per day of a secondary transition dairy supplement.

In splitting out the fresh cow diets, the farm is able to provide additional energy and protein to get these cows off to a good start, Verhoog says.

This was a new approach Reijnen implemented when he started farming in Canada 12 years ago. “We never sorted fresh cows before we started farming here. We found it was hard to find the fresh cows in a large group, and now we can see them right away,” he says.

“The setup has to work,” Reijnen adds. “Not everybody can do it.”

Another feature Reijnen added to his dairy is a fully enclosed 60-foot by 120-foot commodity shed. Dry feeds are stored and loaded within the building.

“I didn’t like storing feed outside. It is always wet, and the birds would eat the feed,” Reijnen says.

His forage crops are stored outside in seven bunker silos, and he is in the process of building an eighth bunker.

The Reijnens rely on a custom operator for fieldwork so they can spend their time focusing on the cows. However, with three boys involved in the farm, they are starting to do more for themselves, including cultivating, cutting and merging. They continue to custom-hire planting, harvesting and packing.

The custom operator only does his own farm and Reijnen’s. “He is pretty keen on his own farm,” Reijnen says, noting that experience helps him know how important cut length and packing can be to the success of a dairy farm.

When it comes time for harvest, Reijnen also appreciates the advice of his farm consultant, who he’s relied upon for years.

“I’ve been working with Henry for 12 years. If I need something, I give him a shout,” he says.

As a farm consultant, Verhoog focuses on multiple items at the farm level, such as cow comfort and observation. He visits the farm weekly or biweekly to help keep an eye on what is happening. Currently, he is helping the farm troubleshoot how to get cows bred back quicker.

“It is more than nutrition,” Reijnen says. Verhoog has been working with the Reijnens since they emigrated from Holland, helping advise with the building of the barn and bunkers right from the start.

“When I want to build a bunker, he brings experience from working with other farms,” Reijnen says.

In addition to the on-farm visits, Reijnen and Verhoog communicate a couple of times a week.

Having been at this game for 27 years, Verhoog says he most enjoys the job when he is able to establish a good working relationship with dairy producers.

“I find you get better results on those farms you can communicate with,” he says. “Good old, open communication is paramount.”

The moment a dairy producer starts feeding from a different bunker, or when he or she sees the dry cows are not eating as much, they should be on the phone with their nutritionist to discuss what is happening, he says.

A good ration isn’t the key to a successful dairy herd, Verhoog says. In fact, it is just the opposite.

“Those farms that do a great job of raising good replacements that become good cows make our jobs much easier,” he says. “Good genetics and good attention to health issues makes it easier to get the milk out with good feed.” PD