This month’s VAS DC305 tip is on parlor performance. Using the parlor performance reports in DC305 helps you take advantage of many of the benefits of daily milk meters plus look for cows that fail to produce the expected amount of milk.

This data will help you:

- Find meters that are not functioning properly

- Identify cows milked in wrong pens

- Monitor employee milking performance

- Evaluate changes in milking procedures to determine their benefits or detriment

The data for this information will vary from one meter manufacturer to another.

There are two parlor performance reports in DC305, one from the MILK command and one from the PARLOR command. While they are very similar, there are two major differences. MILK parlor performance is from the standpoint of the cows and where they are located in their pens in DC305, while the PARLOR is by pens in the presumed order they were milked. The second difference is the MILK report lists errors and problems with the milkings, while the PARLOR report lists errors of cows found in wrong pens during milking. For this article, we will be looking at the PARLOR report.

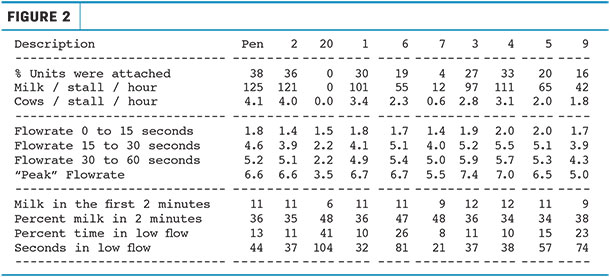

The summary is of one milking (Figure 1). Since this is a PARLOR report, the pens are as the cows were milked in the parlor and the “cows” column may better be described as the number of milk weights from the milking. Even if the cows were not identified but the system knew they were there, they will be counted. Most of the columns are self-explanatory, but a couple that need explanation are “deviation” and “not ID.” The “deviation” is the average deviation from expected milk. The “not ID” is the number from each pen that did not ID when they came in the parlor. A negative number indicates that more cows were milked in that pen than what DC305 has. This is usually due to mixed up cows.

The summary portion of the report is very helpful to monitor milker performance. Look at start times for consistency, length of milking or negative not ID for the number in wrong pens, total production per pen and average duration. The average duration goal for the first 25 pounds is four minutes or less, and for each additional 10 pounds, half a minute or less.

The next section (Figure 2) shows the meter performance. The best overall parlor efficiency measure is pounds of milk per hour per stall. This requires high-producing cows, fast-milking cows with prompt milk removal and smooth, rapid parlor turnover. On a three times a day milking schedule, greater than 100 pounds per stall per hour is considered good and greater than 130 pounds per stall per hour is considered excellent. The best indicator of udder preparation and cow handling is the first two minutes of attachment. The goal for three times a day milking is greater than 14.5 pounds.

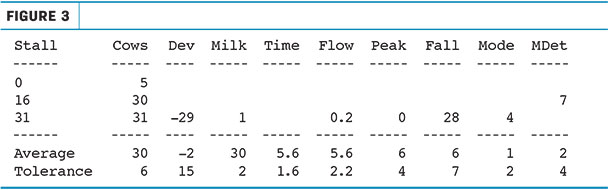

Meter function (Figure 3) is a very important section, which lets you know that a meter is not working correctly before you would normally recognize it. This section will show any stall that was out of tolerance for that milking. If you are seeing the same stall each milking, attention is needed. It shows the stall only if it is out of tolerance. In Figure 3, you will see that stall 31 is flagged for milk deviation of -29, which is out of the tolerance of 15. This is a meter that needs to be looked at for malfunctioning.

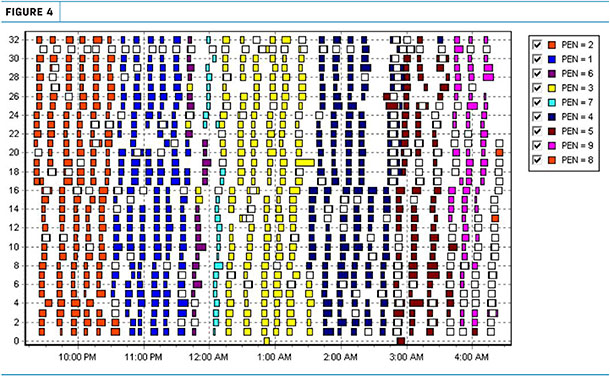

PARLOR also has a very useful graph (Figure 4), which allows you to see a very good overall picture of what is happening in the parlor at a glance. The left side of the graph is the stalls, and the bottom is the times. Each box is a cow. You are able to see how milkers are being attached, how long each cow is being milked by the length of the box, if cows are in wrong pens by mix colors, reattaches – which are the white boxes – and by hovering over any box, you can see all the details for that cow.

Parlor performance reports are extremely important for finding meters that are not functioning properly right away, monitoring employee milking performance and evaluating changes in milking procedures to ensure an efficient parlor.

– Article submitted by VAS

View the previous tip, Lameness Manager.