Not a big “fan” of confusing and conflicting data regarding solutions for ventilation and air circulation on your dairy? Make it easier by referencing unbiased information from a research, product-testing and educational laboratory, Bio-Environmental and Structural Systems (BESS) Labs.

Steve Ford, manager of the lab located at the University of Illinois – Urbana-Champaign, explained how dairy producers can use BESS Labs’ research on fan efficiency and performance to make educated purchasing decisions during the Dairy Strong Conference held in Wisconsin earlier this year.

According to Ford, there are two distinct categories of fans commonly used on dairies that BESS Labs tests: circulating fans and ventilation fans.

Circulating fans

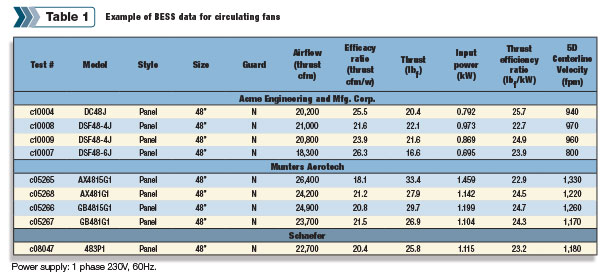

Circulating fans create air movement within a space, like the basket, box, panel or tube fans often found directly above cows at the feedbunk or in freestalls (Table 1).

Click here or on the image above to view it at full size in a new window (PDF, 1.3 MB)

You can evaluate circulating fan performance by selecting from the following drop-down categories on the website: power supply, manufacturer, fan diameter, fan style.

The results displayed for the particular fan will tell you the air flow in pounds of force, or “thrust,” in cubic feet per minute (CFM).

Ford recommended working with an extension engineer or experienced building designer to specify the size, desired air-flow capacity, number and type of fans needed and where they should be located throughout the facility.

After you choose the air flow, size and style of circulating fan that is right for your barn, the next step is to evaluate the options for energy efficiency ratio, measured in CFM per watt. The higher the CFM per watt, the more efficiently the fan uses electricity.

This figure is not only important for estimating energy costs, but it is also used for determining energy rebate qualifications. When comparing the efficiency ratio, Ford recommended limiting the comparison to fans of the same size with similar air-flow levels and the appropriate safety guarding for the intended application.

Ventilation fans

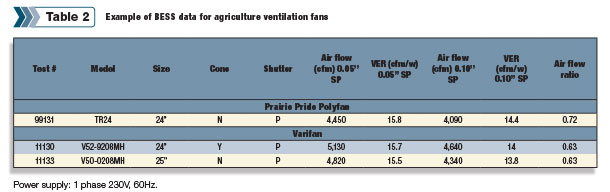

The purpose of a ventilation fan is to provide an exchange of air from one location to another. In some cases, like cross-ventilated barns, these fans are moving large volumes of air; thus, choosing the right fans can make a difference in the ability to move that air efficiently (Table 2).

Click here or on the image above to view it at full size in a new window (PDF, 1.4 MB)

The BESS Labs testing procedure calculates ventilation efficiency ratio based on electrical usage (CFM per watt), as well as air-flow performance. It simulates a real-life barn by varying the levels of static pressure the fan must work against.

This data is based on fans tested with their respective shutters, guards and the standard attachments and drives. Be sure to specify in the search whether or not you are looking at discharge cones because that impacts performance.

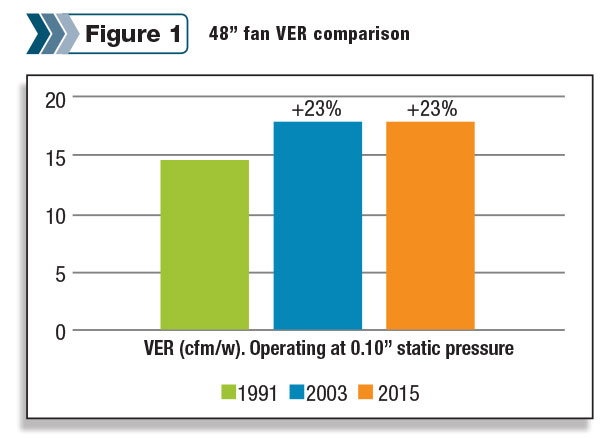

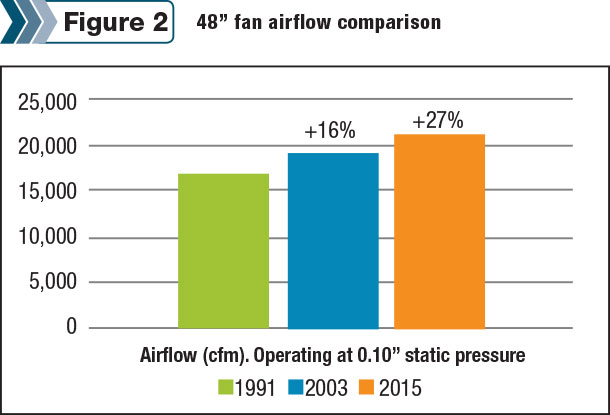

Both fan efficiency and performance have improved significantly over the past few decades.

These trends are illustrated in the tables and figures below. If your current fans have been around for a while, it may be wise to consider the energy-saving benefits of a ventilation system upgrade (Figures 1 and 2).

Other considerations …

When looking to purchase fans, the BESS Labs information can be helpful in figuring out quality of air and ventilation efficiency, but Ford said there are a few more things to consider:

- Quantity of air at different static pressures

- Quality of dealer service and support

- Reliability and life

- Suitability for intended application

- Cost

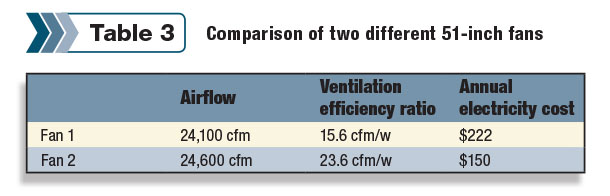

When it comes to estimating cost, be sure to include operating cost. For example, compare two 51-inch fans operating at 0.1 inch static pressure for 12 hours a day and 120 days a year with electricity cost of $0.10 per kilowatt hour.

The savings of $72 per year for each fan can add up quickly (Table 3).

Static pressure is not a factor to be overlooked either. Static pressure is created by resistance to air flow. Evaporative cooling pads, light trap inlets, the amount of inlet open area, curtains and ceiling baffles all add to this effect. Ford noted that as dairy barns are built larger and longer, baffles in particular can create more resistance than people realize.

This increased static pressure means the fan may be operating at a higher pressure than designed and thus lessening the air velocity over the cows. He recommended working with an experienced professional to size the ventilation system correctly.

The barn ventilation system operates where the system curve and fan curve intersect. Figure 3 shows a simple example of how the operating point is affected when an air inlet opening in the barn sidewall is decreased – moving from system curve to system curve 2. The barn static pressure increases as air flow decreases.

Rebate and incentive programs

There are several programs that provide monetary incentives based on BESS Labs’ test data:

- Focusonenergy.com

- USDA-NRCS National On-Farm Energy Initiative

- Individual electric utilities

If you are wondering whether or not a fan has been through these tests, just look for the “certified by BESS Labs” logo on the sales literature. PD

Beyond Print: Evaluate ventilation options for your barn at Bioenvironmental and Structural Systems Laboratory.

-

Peggy Coffeen

- Editor

- Progressive Dairyman

- Email Peggy Coffeen