Few technologies are currently available to effectively treat and/or dispose of dairy washwater, particularly for dairies without a waste storage facility. Dairy washwater contains milk and animal waste, resulting in a wastewater source with high oxygen demand and a significant nutrient content posing environmental concern for ground and surface water. Small quantities reaching water sources can result in fish kills, algae blooms and aquatic habitat destruction.

Washwater also contains a significant amount of liquid, increasing the potential for leaks and spills, an increase in required manure storage volumes and the associated hauling costs, and an increase in runoff potential when land-applied.

Three innovative treatment systems were designed and evaluated for their performance in reducing pollutant concentrations and the associated impacts.

The three systems investigated included an on-site advanced treatment unit (ATU), a bark filter mound and a constructed wetland.

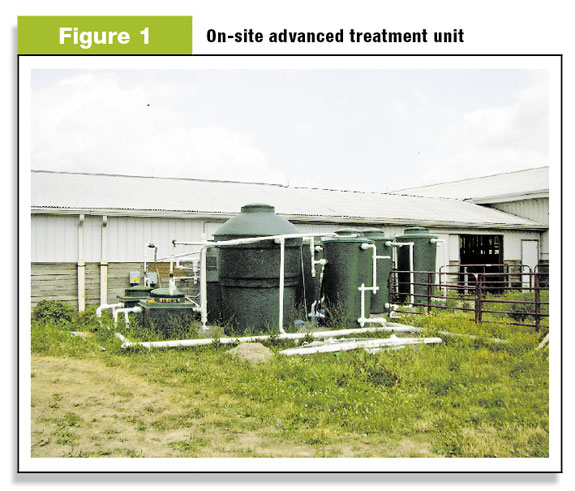

Two ATU systems were evaluated simultaneously (Figure 1).

Each consisted of a settling basin, a recirculation system to provide treated wastewater for dilution of the influent, an aerobic treatment tank that provided an environment for microbial degradation and solid/liquid separation, and an ultraviolet disinfection system.

The two ATU systems varied in the design of the aerobic treatment tank.

One system included a passive solid/liquid separation system (using a primary clarifier and a baffle for scum removal); the second provided a physical filtration barrier for solids removal and a media for biological growth.

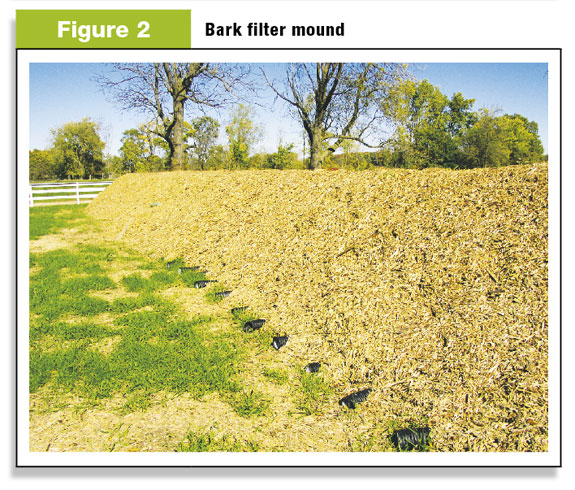

Two similar bark filter mounds were also constructed (Figure 2). Each system contained a septic tank for solids settling, followed by a pressurized pipe distribution system to transport washwater to an above-ground bark filter mound.

The bark filter mound was composed of bark (selected after evaluation of a number of media) to allow the washwater to flow downward through the porous media to promote sorption, filtration, aeration and biological degradation. The washwater then infiltrates through the soil for additional treatment prior to reaching groundwater.

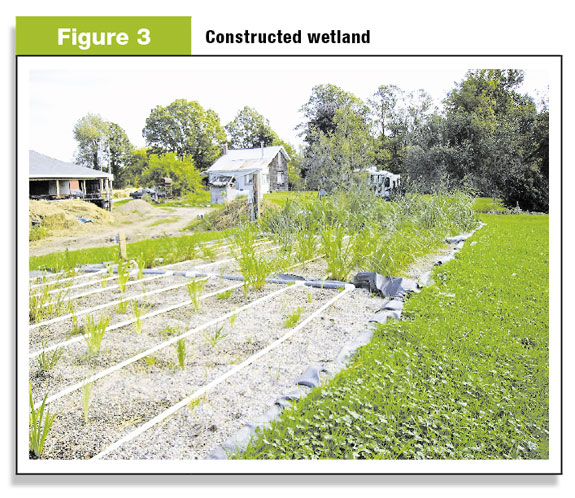

The constructed wetland system also contains a septic tank for primary settling, followed by a three-cell wetland system (Figure 3). Washwater flows through the three cells in series, each cell containing a porous stone media with a variety of native wetland plants.

The first cell is designed for carbon or BOD removal. The second cell is anaerobic (without oxygen) to remove nitrogen. The third and last cell has a similar design to the first cell and serves as a final polishing step.

This design varies from many previous wetland designs in that it has a subsurface distribution system within the three cells that can maintain operation throughout the winter months to provide year-round treatment without freezing. The treated washwater in the wetland system is finally discharged to a subsurface drainage system.

All systems were analyzed for a number of water-quality indicators including oxygen demand, nutrient concentrations and some metals.

Significant removal of pollutants, including carbon and nitrogen removal, was achieved with the ATU containing a physical solid/liquid separation system. Performance was not sustainable for extended periods due to clogging of treatment components as a result of high solids concentrations at the location of the ATUs, which varied significantly from literature values.

Primary settling proved to be critical in removal performance, in particular for all treatment systems that contained any screens or physical barriers.

Increased solids concentrations were a result of management practices; maintaining separation of waste streams can have a significant impact on reducing solids concentrations, improving performance. The results warranted further investigation for washwater with more typical characteristics.

The bark filter mound and the wetland system significantly reduced the pollutant concentrations within washwater, even throughout the winter months. The bark filter mound required regular maintenance of screens to maintain the system. Maintenance of the bark, mainly replacement, will be required after extended use.

Continued monitoring of the soil subsurface will continue to evaluate the potential of metal leaching (a result of the naturally occurring metals within the native soil, which can mobilize due to the increase in loading).

Wetland cells were effective in reducing carbon and nitrogen within their respective cells. The growth of the wetland plants mimicked this removal as the plants flourished in the first cell with high nutrient and carbon availability and decreased significantly in the second and third cells.

Concentrations following the third wetland cell proved to be extremely low, providing effective treatment adequate for disposal in a subsurface drainage system.

A quick recovery of pollutant removal and effluent concentrations in the wetland system following a significant increase in pollutant loadings as a result of a large volume of wasted milk was realized; however, it did require emptying the septic tank. Further research for more detailed wetland design parameters is required to determine maximum loadings and system size.

Treatment systems proved effective in reducing concentrations and are viable alternatives for washwater treatment. Both the bark bed and wetland system were kept in use by the farms on which they were installed and continue to be operated by their producers. Continued testing is required to further develop maintenance and cost requirements. PD

This project was completed at numerous facilities throughout Michigan in cooperation with Dr. Steve Safferman at Michigan State University, USDA NRCS, Michigan Department of Environmental Quality, Michigan Milk Producers Association, Clinton Conservation District, and Aqua Technologies.

Funding was provided from a Conservation Innovation Grant, Michigan Animal Initiative, Michigan Milk Producers Association, Aqua Technologies, Michigan Department of Natural Resource and Environment, and Consolidated Treatment Technologies.

Contact Rebecca Larson, UW-Madison, ralarson2@wisc.edu or Steve Safferman, MSU, safferma@msu.edu for more information.