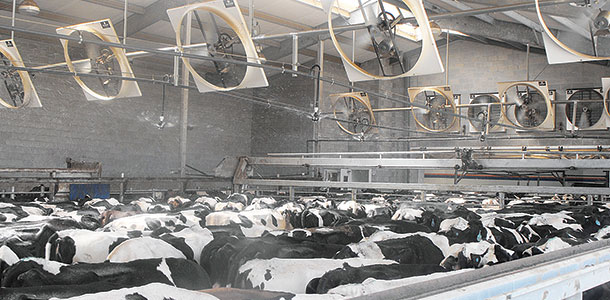

As summer comes to an end, we must remember that heat stress can still play a role in our dairy production and that we still need to be vigilant on heat abatement for our dairy herds. We may be enjoying some cooler weather, but for high-producing dairy cows, the temperature is still running plenty warm for peak production. Days warmer than 50ºF still can create problems in the holding pens and milking parlors where cows are crowded together.

A quick check on respiratory rates in these areas can let you know that your milk yields, reproduction rates and overall herd health is still being influenced by Mother Nature and heat stress.

Any cow with greater than 60 breaths per minute (BPM) or a rectal temperature above 101.3ºF is beyond the stress threshold. This is a great time to try out some of the heat stress applications we reviewed this summer if you have not already put them into practice (Photo 1).

Perform a fall fan check

This is also a good time to do a quick fall fan check by visually inspecting your dairy and performing your fall maintenance program to replace broken fans, blades and motors, as well as cleaning guards and blades. It is good practice to grease bearings in accordance with the manufacturer’s recommendations. Remote lube systems can save valuable labor time and ensure maintenance is completed (Photo 2).

If you have an evaporative cooling system, it is a good time to inspect the pads for bowing and sagging or dry spots that indicate uneven application of water due to clogged holes. Inspect the sump, remove any debris and check the distribution system for leaks.

The same applies to misting systems. Check nozzles and the distribution system for clogs, cracks or leaks and make necessary repairs. It is much easier to do this on a nice, cool day than to put it off until cold weather arrives or – worse yet – to wait until a sudden hot spell next spring and take the dip in milk production.

You should also look at your controls and note your settings for next year, or if you want to, evaluate the effectiveness of your cooling plan and make changes. It is important to document all your notes and make a complete list to give to your supplier so they can order any parts and install them before the next heat-stress season.

In colder regions, many ventilation dealers will perform a fall fan check. This usually includes blowing water out of the lines prior to temperatures dipping below freezing, performing any necessary repairs and conducting a review of the complete cooling system. It is much easier to do the check and repairs today than it is to wait until the next hot day arrives.

The fall fan check is the time to take an extra minute to evaluate hot spots – areas within pens that cows either avoided or were constantly standing. Both of these observations are indications that they were within the stress threshold and were standing to allow air to circulate around them in order to dissipate heat.

Did your cows bunch together in areas that were much cooler? What changes can you make to achieve more even cooling and cow distribution? Make notes while your thoughts are fresh so that when you ask questions later, you can review your thoughts and notes to create a better plan for heat abatement.

Did your heat abatement plan work effectively in reducing your milk loss? After looking at your conception rates and comparing them, did you make improvements over the heat-stress months? Did heat stress have an impact on your claw health? If so, what can you do to change that?

What other areas of your facilities need a heat abatement plan? If you have those notes and thoughts, plus a little research, you can look at some of the new technological changes that have evolved which can create a better environment for the cow and a better return on investment for the producer.

Winter ventilation

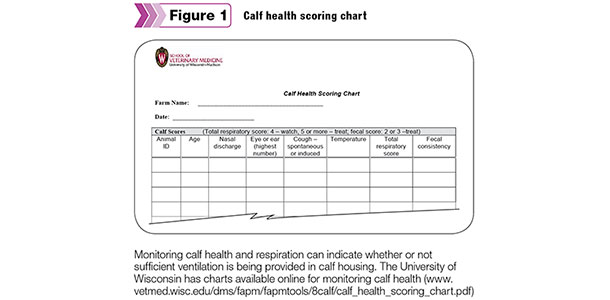

Winter ventilation and fresh air is critical to good herd health. Review your minimum ventilation needs during the fall fan check and remember to review ventilation for your calf barns, especially those in colder regions. Placing calves into a small and isolated habitat creates a microenvironment (Photo 3).

The smaller the environment, the greater the bacterial count. Low airborne bacteria counts are critical to good respiratory health and can be achieved by lower temperatures, good ventilation and good nesting conditions. Failing to have a good ventilation system for your calf barn will play havoc on your return on investment and growth plans.

Gathering respiratory scores and airborne bacterial and ammonia counts in the pens and alleys is a good place to start to monitor and make improvements in calf environments. Monitor your inside and outside temperature and humidity, outdoor wind speed and direction and bedding depth.

Look at the microenvironment of the calf from their level, not where you are standing. I have been in many calf barns where the ventilation appears sufficient, but once I stepped into the microenvironment of the calf, tucked down low under a covered pen where the calf was standing, it was much different.

Click hereor on the image above to downloada University of Wisconsinchart for monitoring health and respiratory rate for calves. (PDF, 265KB)

Click hereor on the image above to downloada University of Wisconsinchart for monitoring health and respiratory rate for calves. (PDF, 265KB)

Develop a minimum ventilation system based on these factors: the type of design you have, the number of animals in that location and your geographical environment. In the Midwest, a simple snow-removal plan or a properly placed shelterbelt can be a dairyman’s best friend in January and February when the snow is deep and the winds are blowing.

Allowing fresh air in and exchanging stale air out of the barn is increasingly recognized as a best practice to maintain good herd health.

It is also critical to make sure any fans that will not be in service are checked for damage or repairs so they can be closed tight or sealed off completely to prevent freezing and icy spots on the edges. Many of the new cross-ventilated and tunnel-ventilated barns have built-in designs that provide a buffer zone (Photo 4). PD

James Kleinke is with Schaefer Fan. He can be contacted by email.

PHOTOS

PHOTO 1: A little exercise and crowding in the holding pen can do a lot of damage. An increased core body temperature of just 0.9ºF can increase the abortion rate.

PHOTO 2: A remote lubrication system is designed for labor savings and ease of maintenance.

PHOTO 3: This calf barn at the Rohe dairy farm in Minnesota has both summer and winter ventilation, as well as tube ventilation. Good ventilation, good nesting and an open environment lead to a healthy and successful calf program.

PHOTO 4: Fresh air is also important in cross-ventilated and tunnel-ventilated buildings, as shown here at Riverview Dairy near Morris, Minnesota. Photos courtesy of Schaefer.

James Kleinke

Schaefer Fan