Beef prices in the last year have provided significant opportunity for aggressive culling and increased cash flow from the sale of less-productive cows. Indicators suggest this trend will remain for an extended period of time, providing producers with a means to both aggressively cull and replace cows at a lower net cost.

Although high beef prices are in place, there can be a significant gap in pay price for cull animals.

Opportunities exist for producers to reduce the spread in price between lower-priced cull cows and those that bring a premium.

To take advantage of opportunities to increase cull cow values, it may be necessary to understand how cows are graded and why premiums are paid for some classes of cows.

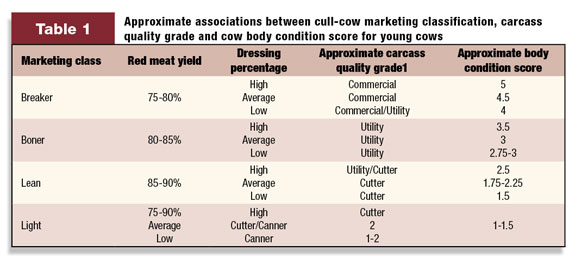

Table 1 shows the breakdown of quality grades for cows and how they relate to body condition score (BCS).

With this discussion focused on dairy cattle, body condition score will be in reference to the five-point scale used in the dairy industry (1 = very lean/thin; 5 = fat/overconditioned).

Beef processors are most concerned with the marketing class when looking at the value of a carcass. Below is a description of each of these:

- Breakers (or Breaking Utility) – Cows with a BCS of 4 or higher, a red meat yield of 75 to 80 percent and considerable muscling. These cows are typically processed into various cuts, including some premium items.

- Boners (or Boning Utility) – Cows with a BCS of 2.75 to 3.5 and an estimated red meat yield of 80 to 85 percent. After merchandisable cuts are removed from the carcass, the rest of the boneless beef will be used for further processing.

- Lean – Cows with a BCS of 1.5 to 2.5 and an estimated lean beef yield of 85 to 90 percent. Carcasses will have very few merchandisable cuts and the majority of the beef will be used for boneless processing.

- Light – Cows will have red meat yield of 75 to 90 percent. Typically carcasses are very lightly muscled and little or no fat. Used nearly exclusively for boneless beef processing.

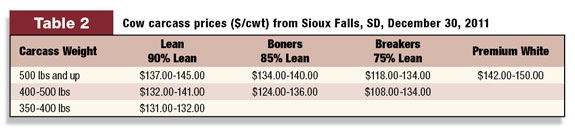

One other market class not mentioned above should also be taken into consideration. “Premium White” cows refer to cows that are relatively young, fat and relatively well-muscled.

These cows would be classified as Breakers. The fat these cows carry would be white in color, indicative of concentrate-fed animals.

Cows fed predominantly hay diets typically produce yellow fat that is less desirable to the American consumer, while cows on a diet containing grain would deposit fat that is white in color and brings a premium to the processor.

Table 2 shows cow carcass pricing from Sioux Falls, South Dakota, for the week of December 30, 2011.

Although it appears that pay price would be lower for Breakers than Boners, and Boners lower than Lean cows, keep in mind that as you move from Lean to Boner to Breaker, typically the cow is in better condition and carrying more weight.

This results in a higher pay price from the carcass. The Premium White class shows a significant advantage in pricing compared to the other classes. Remember these cows are also likely providing larger carcasses, thus increasing the overall pay price.

Using information from Tables 1 and 2, calculations can be made to show the advantage gained in pay price as cattle are better conditioned. Table 3 shows calculations of estimated pay price based on the above information.

The information in Table 3 shows the considerable discrepancy in value of marketed cows. If the average cull cow is a body condition score 2.5 (Lean Boner), she brings $400 less back to the producer compared to a Premium White cow that would ship at a BCS of 4 or better.

The typical U.S. dairy has a herd turnover of greater than 30 percent. A portion of cows in this group are not going to provide the producer with an opportunity for improvement in cull value.

That number will vary from herd to herd, for the most part, based on death rates. Those cows that are culled for milk production, breeding issues and lameness, in cases that are not extremely severe, are prime candidates for carcass improvement.

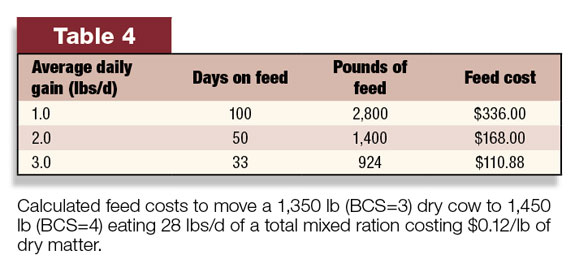

The typical Holstein cow takes about 100 pounds in bodyweight change to move one BCS score on the 1-5 scale.

For example, a BCS 3 cow that loses 100 lbs would expect to fall to about BCS 2, and if she gained 100 pounds, move up to about a BCS 4. With this in mind we can calculate about how much time and feed expense it would take to move a cow one BCS ( see Table 4 ).

As the example clearly demonstrates, it does not pay to use this approach if animals are fed a poor diet with relatively low average daily gains.

High rates of gain are achievable in cull cows with an adequately formulated diet and the removal of milk production as a nutrient sink.

A very good source of feed for cull animals could be refusals from the lactating herd. Unless this supply of feed is heavily sorted, it should provide a very good source of feed that should have the energy available to allow cows to reach realistic economic growth targets.

An analysis should periodically be performed to determine if refusals are in fact providing the nutrients needed. Another option would be for the herd nutritionist to formulate a low-cost diet that could meet the demands for gain needed to move animals to a more marketable carcass class.

Another opportunity to improve economics around culling is to reduce the number of metabolic and/or reproductive disorders around freshening.

This area typically has room for improvement on most dairies. With improvements in intake and condition around freshening, and all-around transition management, fewer cows will leave the herd in early lactation, a period of time that can be difficult to produce a quality cull cow carcass.

With historically high beef prices, opportunities exist to increase cash flow through increasing marketability of cull cows. No time is better than now to meet with your management team and put a plan in place to take advantage of premiums paid for well-conditioned cull cows. PD

References omitted due to space but are available upon request to editor@progressivedairy.com .

—Excerpts from Diamond V Nutrition Line e-newsletter

-

Jeff Mikus, Ph.D.

- Technical Service Specialist

- Diamond V

- Email Jeff Mikus, Ph.D.