California’s San Joaquin Valley is home of both the largest dairy herd and the worst air quality in the U.S.

The San Joaquin Valley experiences high levels of ozone and particulate matter pollution and, according to National Ambient Air Quality Standards, must require mitigation techniques and technologies from all sources of pollution.

Fermented feedstuffs such as silage, rather than animal manure, has been found to be the greatest source of ozone precursor gases from dairy farms.

The San Joaquin Valley Air Pollution Control District implemented rule 4570 in 2006 to limit emissions of VOCs from confined animal facilities, focusing on dairies. Mitigation strategies first revolved around manure and lagoon management. In 2011, an amendment was placed to include feed and silage management.

The amendment requests that a farmer choose several mitigation measures to reduce silage gas losses. A more detailed explanation of the rule can be found here (Rule 4570-Confined Animal Facilities) as well as specific examples of mitigation techniques.

We recommend that dairymen nationwide review this rule because it shows how such regulation can turn out. The rule not only provides regulatory restrictions but an opportunity to simultaneously minimize dry matter (DM) losses.

What do we know about dry matter losses from silage?

Entire crops such as corn, sorghum and other forages can be chopped, compacted and preserved as silage, a fermented feed, to be fed to animals throughout the year. Prior to storage, layers of chopped feed are compacted to drive out oxygen.

Utilizing optimal management techniques, dry matter (DM) loss from a silage pile can be as low as 8 percent, a value often achieved in the Midwest and East. Poor management conditions (such as uncovered piles) can result in excess of 30 to 40 percent DM loss.

In the San Joaquin Valley, DM losses of 20 percent are quite typical and partly caused by hot and windy conditions throughout most of the year. According to our research, these DM losses are predominantly the result of gases containing carbon (aka volatile organic compounds – VOCs) and nitrogen (aka oxides of nitrogen, NOx).

These two gas groups escape into the atmosphere and are the precursors responsible for ozone formation. However, these escaping VOC gases include volatile fatty acids and alcohols, which are valuable nutrients we want to get into the cows rather than into the atmosphere. Reducing gaseous losses will therefore mean a win-win situation for both the environment and the bottom line of the dairyman.

What are high-risk (gaseous loss) phases of my silage pile?

The most gaseous loss during the entire silage life cycle occurs during its first and last phase. The first phase after the pile is completed and just covered mostly generates the so-called NOx gases. These yellow-brown NOx gases, also commonly known as “silage gas,” present a major worker health and environmental concern. Indeed, inhalation of this yellow-brown gas that generously lingers near the ground can cause serious respiratory distress and even death.

The last phase of the silage life cycle, the open face as well as the feedout phase, is where most VOCs are lost to the atmosphere. These VOC losses are the main contributor to gas losses from silage and also the main environmental and economic concern. According to our research, most of the gases that can escape into the atmosphere will do so within 12 hours.

This means if you have very large piles with surfaces from which you only deface half or less of the total area per day, you will have maximum losses. Conversely, if your pile has a small face (e.g., an Ag Bag), and you feed at a greater depth per day, then your losses from the actual pile will be much reduced.

What makes a silage pile good or bad?

Air speed, temperature, porosity and surface roughness (surface area) are physical influences that can alter silage quality and gas production. Orientation of the silage face can minimize sunlight exposure, and protective barriers can minimize wind speed over the pile. Smooth defacing reduces roughness and thereby surface area of the face.

A good silage pile will be largely air-tight and sealed immediately after compacting. Never let a new pile sit uncovered for many days or even a week, or you risk huge losses.

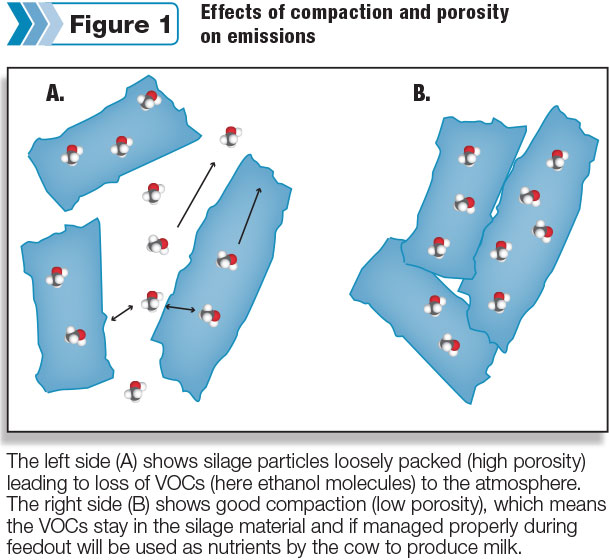

Remember, compaction is key. With increased compaction, porosity is decreased. Porosity spaces are areas where oxygen can pool, slowing down the ensiling process and decreasing silage quality. Those VOCs are nutrients, such as ethanol, that can go into the air and will do so if they have exposure to pore spaces (Figure 1).

How is silage stored?

The first storage type is a standard pile. Layers of chopped fodder are placed and compacted using a tractor to drive out oxygen. Once the pile is fully compacted, a UV-resistant and oxygen-tight plastic sheet is placed over the pile. Weights, such as used tires, are placed close together to minimize headspace and maintain a gas-tight seal.

The second storage type is a long sausage-shaped cylindrical bag (i.e., Ag Bag) made out of similar UV-resistant and gas-tight properties. This form of bag storage is accomplished by horizontal rather than vertical compaction.

Silage bags typically have a lower compaction rate than the standard pile compacted with tractors, but the former is able to retain a more gas-tight seal.

The third storage form is the silage bunker, similar to a standard pile but with concrete sidewalls. The feed is covered on top with a similar tarp and tires as in the standard pile.

From the standpoint of minimizing gaseous losses, we have found that the long, sausage-shaped silage bags perform best simply because the face exposure to air is minimal. The disadvantage is that they require substantial space. We also found bunkers are superior over the standard pile because, in general, compaction can be achieved at better rates, leading to lesser emissions.

Do silage additives work?

While numerous microbial additives have been reported to improve silage quality, our research has not shown effects of those on decreasing gas emissions. Many of the microbial additives we have studied (including Lactobacillus buchneri, Lactobacillus plantarum and propionic acid mixtures) even stimulated the production of VOC emissions.

We found only one silage additive that inhibited the production of multiple VOCs, namely potassium sorbate. Potassium sorbate addition at 0.1 percent fresh forage-mass basis has been shown to reduce production of ethanol, methyl acetate and ethyl acetate – three of the main VOCs from silage.

Further research is needed to demonstrate how potassium sorbate performs under farm conditions and at what dose. We found that air quality regulations favoring additives to reduce gas losses are poorly informed and might even lead to increasing emissions compared to those from untreated piles.

Finally, VOCs have a high affinity to water, which means adding some water into your TMR wagon can aid in locking in those VOCs into the liquid/solid phase, ensuring these nutrients enter the cow and not the air, a practice already used across the industry. PD

PHOTO: Fermented feedstuff such as silage (rather than animal manure) has been found to be the greatest source of ozone precursor gases from dairy farms. Photo by Lynn Jaynes.

-

Frank Mitloehner

- Professor

- Air Quality Cooperative Extension Specialist

- Department of Animal Science

- University of California – Davis

- Email Frank Mitloehner