Dave Jauquet farms with his wife, Stacy, 10 full-time employees and two part-time employees at Jauquet Dairy LLC in Luxemburg, Wisconsin. They milk 535 cows three times a day, with fresh cows milked six times a day. The herd averages slightly more than 31,000 pounds of milk with 3.75 fat and 3.15 protein.

The farm operates 377 acres and purchases its remaining feed requirements, including shredlage, haylage, high-moisture corn, dry corn, distillers grain, gluten, soy hulls, vitamins, minerals and a few select additives.

The farm has a 55-pound dry matter intake average on the milk pen, which equates to a 1.7 feed efficiency. It is a number Jauquet watches month-by-month and as he switches feeds.

He also keeps a close eye on shrink or the amount of feedstuff dry matter purchased that was not consumed by the cows. On a 1,000-cow dairy, if the feed cost is $.11 per pound of dry matter and the cows have an average dry matter intake of 54 pounds, the farm could save $22,000 per year for every 1 percent decrease in shrink.

“On my farm, we need to pinch pretty much every penny that we can get so we can continue to grow our business,” Jauquet said.

While speaking at the Vita Plus Dairy Summit in Baraboo, Wisconsin, on Dec. 9, he suggested dairy producers find the low-hanging fruit in the areas of harvesting, packing, covering, mixing and feeding. “Do what’s simple. Start with the easy stuff,” he said.

On Jauquet’s farm, he focuses on feed shrink in five areas.

1. Truck scale

The farm has a scale on-site to weigh every load of feed that comes in and every load of milk going out. He double-checks the weight slips, and if the supplier is consistently off, he will have a conversation with them. “That’s when the scale pays for itself,” he said.

2. Bins

Jauquet installed three bins, each one large enough to hold a semi load of feed. The farm’s most expensive feeds – protein mix, dried distillers grains and soy hulls – are kept in the bins where wind, birds or rain cannot shrink away the feed. He also uses the farm’s existing Harvestores to store high-moisture corn.

3. Feed pile

Corn silage and haylage are kept in large, long piles, one for each feed. They start feeding from one end; then at the beginning of harvest, they switch to feed from the other end, while they fill in the end that was just vacated.

Large cement blocks are used to create a 4-foot wall to line the silage pile. Before filling, the walls are wrapped with a sheet of black and white plastic, then a sheet of oxygen barrier film, both of which are later wrapped over the entire pile. At the seam of the pile, where the old meets the new, Jauquet said they overlap the wrapping materials by 8 to 10 feet and don’t see much spoilage at feedout.

When it is time to uncover a portion of the pile, either Jauquet or his full-time feeder will walk with a pitchfork to throw off any rotten feed. He figures it takes about 10 minutes and greatly reduces the amount of discarded feed compared with using a skid loader bucket or defacer. “You have shrink anyway. Don’t make it worse than it is,” Jauquet said.

Each day, a portion of the haylage and corn silage is moved via skid loader to the feed center, where it is kept under roof until it is loaded in the mixer.

4. Feed center

Jauquet converted an old machine shed into a feed center, where the mixer is backed into a pit under three augers from the large bins and two augers from small bins that hold the prefresh and post-fresh custom mixes. The mixer stays in that location until all feed is loaded for each batch. “Everything is indoors. When it is windy, we close the door between loads so that feed isn’t blowing all over,” Jauquet said.

On the floor in the mixing center are piles of haylage, corn silage and pre-batches for dry, prefresh and fresh cows. Mixing pre-batches allows for the processing of hay or straw used in those rations, speeds up the process of feeding and can be done at anytime.

Once a pile is cleared from the floor, Jauquet or the feeder uses a broom and shovel to clean up the rest. “After you scrape the floor with a skid steer bucket and you think you have it clean, take the broom and shovel to it, and you’ll clean up well over a skid steer bucket every time,” he said.

5. Feeding

“Overfeeding is a tremendous amount of shrink,” Jauquet said, adding it is important to put in the mixer what it says to do.

“If you need 98 pounds of bypass fat, add 98 pounds. Don’t just dump in two bags and call it close enough,” he said. For instance, if fat is $.75 a pound, an extra 2 pounds per batch is $1.50. If feeding 10 batches a day, that’s $15 a day. “It’s the very little things that add up to a lot,” Jauquet continued.

On his dairy, Jauquet feeds to zero refusal. “I adjust all of the diets every morning. I’m the one that gets called if cows are running low. I’m the one that gets to go there and start feeding. It’s a fine line to walk, but I feel it is well worth it in cost savings,” Jauquet said.

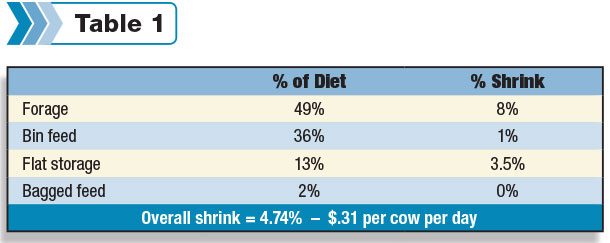

Overall, the farm averages 4.74 percent shrink, which equals $.31 per cow per day. “This is a big number, and I wish I could improve on this,” Jauquet said. PD