BMR corn hybrids are gaining popularity among silage growers looking to improve crop production and nutrient value. To get the most from BMR corn silage, consider its differentiating characteristics and how this feedstuff will fit within your operation.

For dairy producers, the right BMR hybrid for silage production could be the answer for more milk production and higher profits. But first it is important to understand BMR hybrid options through research and input from your agronomic and nutritional advisers.

What is BMR?

BMR is a natural gene mutation discovered in the early 1920s. Besides having a distinctive brownish tinge to the corn leaf mid-rib, BMR corn plants contain less lignin, the indigestible portion of the stalk.

With less lignin, BMR corn is ideally suited for silage production, creating silage with higher neutral-detergent fiber digestibility (NDFD).

High digestibility is important because every 1 percent increase in NDFD equals a 0.55-pound increase in milk production per cow each day, according to calculations by Dr. Michael Allen at Michigan State University.

Research also shows that each percentage point increase in NDFD translates into a 0.37-pound increase in feed intake per cow per day.

BMR gene mutations

Dairy producers who are considering feeding BMR corn silage should realize that all BMR hybrids are not alike. For years, researchers have studied the differences in four BMR gene mutations: bm1, bm2, bm3 and bm4.

Of these gene mutations, bm1 and bm3 have been identified as the highest-performing ones and are the only BMR varieties available commercially.

Research consistently shows the bm3 gene has the highest digestibility in cows. Studies as early as the 1970s show bm3 has higher digestibility than conventional corn hybrids and other BMR gene mutations.

Another study concluded once again that bm3 had the lowest level of lignin among all BMR mutations.

Researchers also have studied the bm3 gene extensively in lactation trials. In 16 research trials since 1999, cows fed this type of BMR silage produced an average of 4.8 pounds more milk per day compared with those fed conventional silage.

Yield improvements

Early BMR corn hybrids on the market were known to be lower yielding than conventional corn silage hybrids. Since then, corn breeders have continually improved agronomic characteristics and tonnage yield of BMR corn. Newer bm3 varieties yield competitively with other corn silage hybrids.

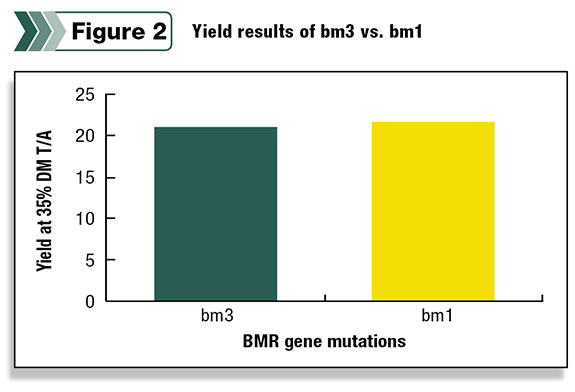

Consider yield data collected in field trials across nine states from 2010 through 2012.

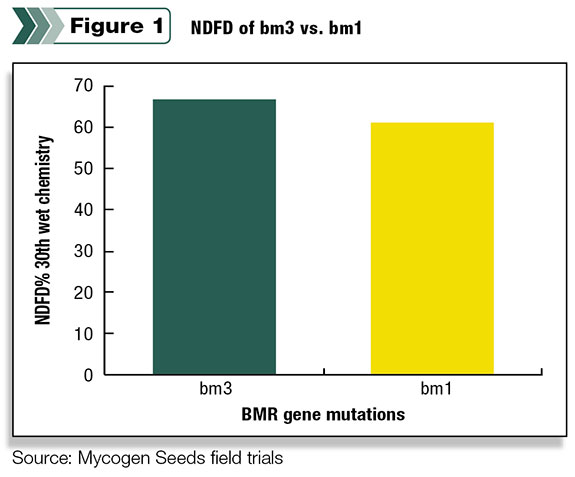

In a three-year period, the difference in yield between bm3 and bm1 corn silage averaged less than a half-ton per acre at 65 percent moisture ( Figure 1 ).

The difference was clear, however, in regard to digestibility.

In the same three-year period, BMR hybrids with the bm3 gene had an NDFD advantage averaging 6.4 percentage points above bm1 BMR hybrids.

Therefore, bm3 varieties excel when it comes to performance in the cow â achieving higher corn silage value, greater feed intake and higher milk production.

On many dairies, the higher corn silage digestibility from bm3 BMR hybrids means producers can feed higher levels of forage and less grain.

This results in a higher return on investment â a top priority for many dairies.

Factors for silage selection

With seed companies developing new options for BMR silage hybrids, it is important to weigh the priorities of your operation and how BMR can help you meet your goals.

Decide what outcomes you want from corn silage and consult trusted agronomists and herd nutritionists to select the best BMR variety.

Ask your seed supplier which gene mutation is in the BMR hybrid you are considering and ask to see digestibility and milk production data as well as yield results.

The true measure of your hybrid is not apparent in the field but rather when the work is done in the milking parlor. Make sure you understand the differences among BMR hybrids before deciding which are best for your operation. PD

Karl Nestor has a Ph.D. in dairy nutrition from Ohio State University and is employed by Mycogen as a senior nutritionist based in Ohio.

References omitted due to space but are available upon request. Click here to email an editor.