Everyone is scrambling to provide healthy, balanced rations for dairy cattle while dealing with changing feed prices and fluctuating ingredient supply. One component of dairy rations that constitutes a large expense, yet is critically important for maintaining production in high-producing dairy cows, is protein and amino acid nutrition.

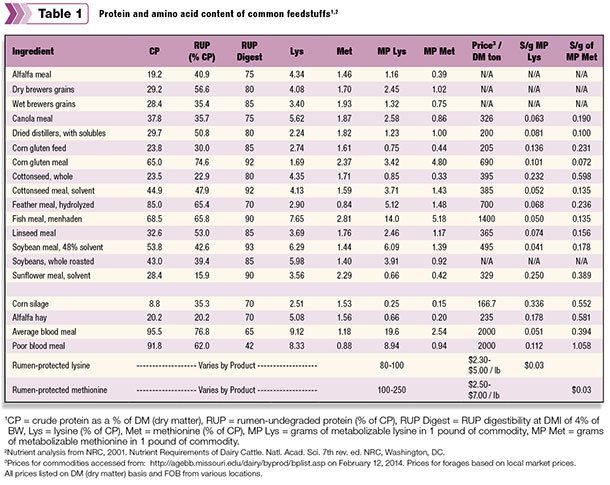

Nutritionists have a variety of ingredients available to use as sources of protein for the dairy cow ( Table 1 ). Each of these ingredients has unique characteristics which alter the amount and type of protein and amino acids provided to the animal.

For example, a relatively large amount of the protein from corn distillers grains escapes rumen degradation (50.8 percent). However, a pound of distillers would only provide 1.23 g of lysine to the animal. This is accounting for the concentration of lysine as well as the digestibility of the protein that escapes rumen degradation.

Now, let’s contrast the amount of lysine provided by distillers with the amount of lysine provided by soybean meal.

A smaller amount of the protein in soybean meal escapes rumen degradation (42.6 percent), but because of the greater digestibility of the escaped protein as well as the greater lysine content, a pound of soybean meal would provide 6.09 grams of lysine to the animal. This is almost four times as much lysine supplied to the animal.

Of all the commodities available for sources of protein and amino acids, blood meal probably has the most extensive use in North American diets.

Historically, blood meal has been an ingredient which is nutrient-dense (more than 90 percent CP), escapes rumen degradation (more than 80 percent rumen escape) and contains a significant amount of lysine (9 percent of CP). Additionally, the price of blood meal has also been competitive with other lysine sources for dairy cows.

However, recent trends in the number of cattle and hogs going to slaughter have changed the economics of feeding blood meal. The limited supply and increase in price of blood meal has forced many nutritionists to search for alternatives. The question commonly being asked is: “What can I feed to replace blood meal, and is it going to be cheaper?”

It is important to consider several factors when answering this question.

• The availability of some ingredients may be limited. Commodities such as fish meal or feather meal may be more prevalent in certain areas.

• The variability in quality of these ingredients – All commodities vary in quality to some extent, but some protein sources may be more susceptible to variability. For example, blood meal is heated and dried down from a high-moisture liquid to a very dry feedstuff. If the blood meal is overheated, the protein becomes bound, and as a result, is essentially unavailable to the animal.

• The price of the commodity – Comparing the price of different commodities based on a ton is not appropriate because of the amount and type of nutrient each commodity supplies. A more appropriate comparison for protein supplements is to compare the ingredients on a dollar per unit of nutrient supplied.

As an example, if we were including blood meal in the ration as a source of lysine for the animal, the cost to supply 1 gram of metabolizable lysine when blood meal is priced at $2,000 per ton is approximately $0.05 (Table 1).

Corn gluten meal, priced at $700 per ton, may seem like an attractive alternative; however, the price to supply 1 gram of metabolizable lysine from gluten meal at this price is over $0.10 per gram, or almost double compared with blood meal.

In addition to commodities, there are other options when it comes to meeting amino acid requirements. The feed industry has developed various rumen-protected amino acid products which are either one specific amino acid or blended ingredients which may provide multiple amino acids to the small intestine of the cow.

These products have the advantage of being consistent compared with a byproduct or commodity which will vary from batch to batch. This applies to not only the amount of nutrient supplied, but also the amount of nutrient available to the animal.

Part of the variability of commodities includes the amount of protein or lysine in each batch as well as the digestibility. A quality rumen-protected amino acid product will provide a consistent source of intestinally available nutrient to the animal.

The same characteristics used to evaluate commodities need to be applied to the rumen-protected products as well. Just because a product is protected from rumen degradation, it does not necessarily mean the nutrient is available to the animal.

The product could be so well protected that it escapes rumen degradation and intestinal digestion and ends up in the feces. Estimates of rumen degradation and intestinal availability should be available for each product, which allows for an estimate of the amount of metabolizable lysine provided.

Typically, when it comes to providing a specific intestinally available nutrient, rumen-protected amino acids are more cost-effective compared to other commodities.

If a rumen-protected product is priced at $2.30 per pound and a pound of the product supplies 95 grams of metabolizable lysine, then the cost per gram of metabolizable lysine is only $0.025 per gram. This is considerably less expensive than other commodity sources (Table 1).

Ultimately, it is important to review your feed options and select protein supplements from feedstuffs available to you at the best price, deliver the nutrients successfully under the conditions of your operation and provide the amino acids to the cow so she can milk at her genetic potential. PD

Dr. Kevin Herrick is the 2013 recipient of the Midwest ADSA Young Scholar Award and the ADSA Graduate Student Paper Publication Award. Herrick completed a Bachelor of Science in animal science, a Master of Science in ruminant nutrition and a Ph.D. in dairy science from South Dakota State University.

PHOTO

Comparing the price of different commodities based on a cost per ton is not appropriate because of the amount and type of nutrient each commodity supplies. Photos by Ray Merritt.

Kevin Herrick

Dairy Technical Service Manager

Kemin Industries