Editor’s note: The following is the second part of a two-part article series regarding diesel fuel injection systems. Click here to see part 1. In my last column I began discussing diesel fuel injection systems, including some background information as to how technological advances such as this one came about. In this article I’ll continue discussing fuel injection, as well as other changes that were made in the diesel and overall automobile industry. When electronics were first introduced into the automobile industry, they were pretty basic. Diesels were among the last to have electronics incorporated into the engines. Many different electronic parts were created, beginning with the addition of a “computer” to the engine.

This computer, as previously discussed, monitors the atmospheric pressures, which plays a big role in fuel injection. It monitors the air pressure at which the fuel is and will be delivered into the engine.

The computer also monitors every cylinder that fires off. I mentioned the summarized version of the combustion cycle in the previous article.

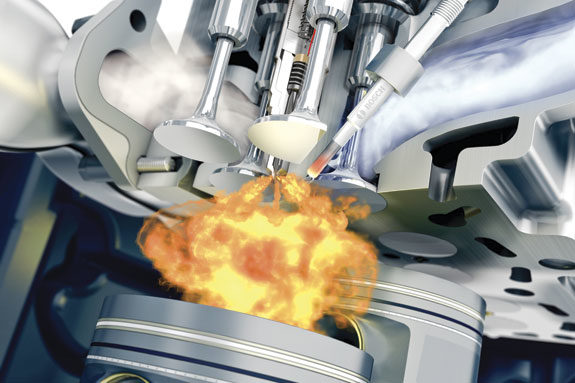

The image above right is an example of the explosion or combustion that occurs within a cylinder during the cycle. This occurs when fuel is injected into a cylinder on top of the piston at a high pressure and timed precisely.

When the valves close and the piston moves upward, a spark ignites the fuel, causing the explosion that pushes the pistons down. This is only one of the steps though, all of which the computer monitors.

So basically the computer can analyze your engine and how well it runs. The computer can detect if a cylinder has had a slower power stroke than normal and will know to compensate for that slow stroke in the next combustion cycle.

After electronics were introduced, the diagnostic part of checking the engine fell into place. Engines are now set up to where certain parts of the engine will send a message if it detects that it is not functioning properly, similar to the tale-tell signs mechanics look for when visually inspecting vehicles and engines.

The engine and its parts are the monitors and the messengers that notify you, the operator, if something is starting to go awry, or if there are indications of a possible failure.

All in all, two major advantages that stemmed from the development of electronic fuel injection were that now a much better fuel economy can be obtained and better emissions standards were created.

Other factors that were also taken into consideration when electronics first started making an appearance in engines included the improvement of vehicle aerodynamics. The front end of trucks and other vehicles were softened to improve them aerodynamically.

Today, you hardly ever see any cab-over semi trucks. You see trucks that have a smaller front end and side wings.

Other improvements include the development of cruise control and the auto shift.

Like I said in the last article, the advantage of electronic fuel injection boils down to the fine controls that the operator is able to monitor. PD

PHOTO

The engineâÂÂs computer monitors every cylinder that fires off. Photo courtesy of The Bosch Group.

This summer we will discuss air conditioning systems in vehicles. What other topics would you like to learn more about this year? Send your questions to: dario@progressivedairy.com