Most independent advisers concur that proven, quality forage inoculants are a key part of the overall management package required to produce high-quality silages. Traditionally inoculants have contained various species of homolactic acid bacteria (e.g., Lactobacillus plantarum, Pediococcus pentosaceus) to get fast, efficient production of lactic acid to shut down plant enzymes and prevent growth of undesirable microorganisms (e.g., clostridia, enterobacteria). However, silage produced this way may heat and spoil during feedout, since lactic acid does not have strong antimicrobial properties.

To prevent aerobic spoilage at feedout, we need to add or produce something in the silage that will prevent or inhibit the growth of yeasts – which are the main initiators of instability when the silage is exposed to air.

Although lactic acid itself has no direct anti-mycotic effects, other organic acids (e.g., propionic and acetic) do. In the mid-1990s researchers at a research institute in Holland discovered that a specific lactic acid bacterium, Lactobacillus buchneri, isolated from corn silage samples that were not heating, was able to produce moderate amounts of acetic acid from the lactic acid produced during the initial phase of the ensiling fermentation. In a recent meta-analysis of published data from studies with L. buchneri, Kleinschmit and Kung showed that silages inoculated with high dose levels of the organism were significantly less prone to heating than untreated silages, while silages treated with more conventional dose rates (less than or equal to 100,000 colony-forming units per gram CFU/g of forage) were not.

Using this high dose rate approach (400,000 CFU/g for silage; 600,000 CFU/g for high-moisture corn), L. buchneri 40788 has been shown to be highly effective in reducing or preventing heating and spoilage in a wide range of preserved feeds on commercial dairies globally. Forage crops successfully treated include grass, alfalfa and mixed haylages; grass, alfalfa and mixed dry baled hays; horseage; corn silage; sorghum silage; barley silage; wheatlage; oatlage; ryelage; high-moisture corn (all types: HMEC, HMSC, cobblage, etc.); high-moisture small grains; pea silage; triticale and pea/trit mixtures; sugar cane silage; sugar beet pulp; sweet corn waste and dry cereals (“soda grain” alternative).

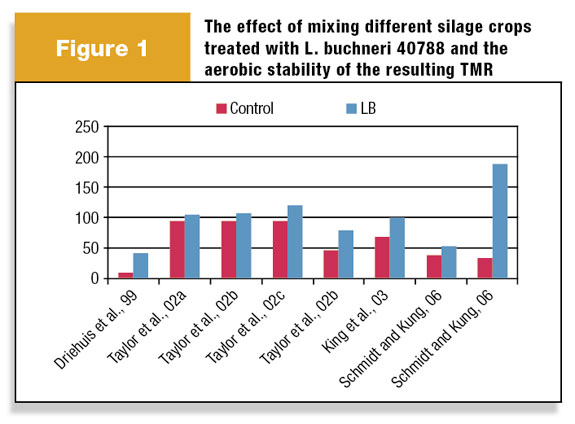

The effects of L. buchneri 40788 on silages have also been shown to carry over into the TMR. Kung summarized the effects of treating several forage crops with L. buchneri 40788 and the aerobic stability of the resulting TMR mix. All studies showed improved bunk life of the TMRs made with inoculated silages (See Figure 1 ).

While yeasts are directly responsible for virtually all the heating events in silages, controlling their population also has a significant impact on inhibiting the development of secondary/opportunistic spoilage microorganisms. For example, after yeasts have destabilized the silage and raised the pH, molds and bacteria can grow, resulting in highly spoiled, potentially hazardous feed.

In addition to causing palatability issues, reduced animal performance and respiratory problems, molds can produce specific mycotoxins under certain circumstances. Some mycotoxins mimic sex hormones and therefore can interfere with normal reproductive physiology in the cow, leading to problems with conception and abortion, while others can cause serious health issues, in addition to negatively impacting performance.

Recently researchers at the University of Florida – Gainesville looked at the efficacy of treating rust-infested corn with the high-dose L. buchneri 40788. In addition to causing direct field yield losses, rust in a crop can predispose the crop to the growth of opportunistic pathogenic molds and potentially mycotoxin production. The study involved a corn crop that was naturally infested in discrete patches in the field at the time of the harvest. Inoculation with 400,000 CFU/g L. buchneri 40788 reduced mold counts in high rust silages 80-fold and increased their aerobic stability by about 75 percent. The aflatoxin levels in untreated, rust-infested silage were 5,000 parts per billion (ppb), considerably higher than the FDA action level at 20 ppb, while there were no aflatoxins detected in the inoculated silage made from rust-infested material. Consumption of low concentrations of aflatoxins by sensitive animals can lead to death in 72 hours; animals that ingest feed contaminated with non-fatal levels of aflatoxins can suffer impaired health, reproductive dysfunction and productivity loss.

One of the more important groups of spoilage bacteria in silage are Clostridium spp., which occur naturally in soil and manure. Some clostridia species can produce butyric acid, leading to silage that is difficult to feed; others produce toxic biogenic amines, which can cause significant health and reproduction issues.

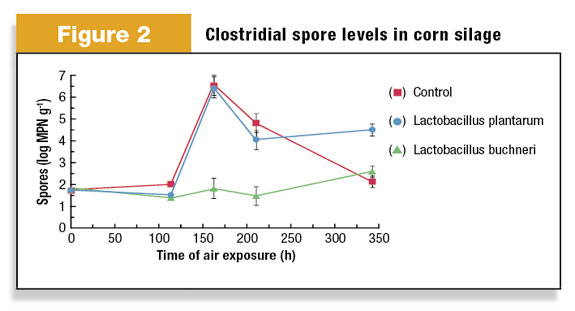

A recent study at the University of Turin showed that corn silage with a relatively low clostridia count can become contaminated when it becomes aerobically unstable. The oxygen that penetrates through the face of a silo can be used by aerobic microbes (e.g., yeasts) to grow and cause the pH to increase. This aerobic growth can re-establish anaerobic conditions behind the face that, with the elevated pH, allows clostridia to become active and grow.

The Italian group found that the clostridial spore counts per gram of fresh, untreated corn silage increased dramatically, from less than 100 (2 log) to about 5,000,000 (6.5 log) after air exposure. The effectiveness of two microbial inoculants, one containing L. plantarum and other L. buchneri 40788, to prevent clostridial growth was evaluated. While treatment with L. plantarum had no inhibitory effect on the clostridial activity in corn silages, those treated with L. buchneri 40788 remained aerobically stable (approximately 300 h) and prevented the development of clostridial spores. (See Figure 2 .)

Corn silage is a staple component of the diet fed to ruminants, and feeding poorly fermented or contaminated silages needs to be carefully managed. Take samples properly to obtain accurate test results and find the specific cause of the problem. The best decision with badly spoiled feed is to remove it from the diet, which can be done with moldy patches of feed. This is not practical if the bulk of the silage has been poorly fermented or been affected by clostridia, for example. In these situations, the feed can be diluted with clean feedstuffs, and may also benefit from the inclusion of specific components and/or feed additives to maximize production. Best of all is to use good silage management practices, including inoculants proven to prevent silage spoilage, to ensure you produce top-quality, hygienically preserved feeds for your herd. PD

References omitted due to space but are available upon request by sending an email to editor@progressivedairy.com .

-

Renato Schmidt

- Forage Products Specialist

- Lallemand Animal Nutrition

- Email Renato Schmidt