Almost every dairy producer has questioned whether it makes sense to hire a custom harvester or complete harvest themselves. Some have done in-depth analyses of the two strategies by considering different financial variables, such as cost of ownership, labor, depreciation, interest, repairs and how their balance sheet would be affected. However, all of that is often thrown out the window in favor of one very tangible and a few intangible considerations.

The one tangible consideration is the potential for more or less milk production that comes with the decision. While the cost comparison of the two strategies seem to loom large, the bottom-line decision is influenced far more by a change in milk production based on forage quality.

Keeping in mind that Production – Cost = Profit, we’ll walk through what an example partial budget may look like for this proposed change. We will use a seven-step process Penn State University recommends to evaluate any proposed change on a dairy.

Step 1. State the proposed change

In this case, let’s say the proposed change is to have all haylage and corn silage harvest operations custom hired.

Step 2. List the added return

Selling off existing equipment could be an added return, but we’ll use zero for this example because the dairy either has no equipment to sell off or it has depreciated and has little value. A more important consideration is the potential for increased milk production. This is the tangible measurement that drives the entire decision-making process and could be considered for or against custom hiring for the harvest operation.

For example, if the producer has a worn-out chopper without an efficient kernel processor, or he or she is too busy in the spring to get haylage harvest started in a timely manner, then a custom harvester may make more sense. On the other hand, as a new customer, the dairy may end up at the bottom of the custom harvester’s list and they may harvest the crop too late, sacrificing quality and negatively impacting milk production.

In this partial budget, we’re going to look at a swing of 2 pounds of milk up or down, depending on which strategy makes the most sense. That may seem like an arbitrary number, but such a swing in production is very reasonable, and perhaps minimal, to assume based on forage quality and processing differences.

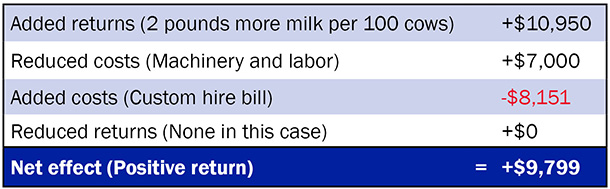

In this example, let’s assume the producer believes the decision to custom hire for the harvest season will gain an average of 2 pounds of milk per cow throughout the year. For every 100 cows, that’s a total of 73,000 pounds more milk per year. At $15 per hundredweight (cwt), the added return would be $10,950.

Step 3. List the reduced costs

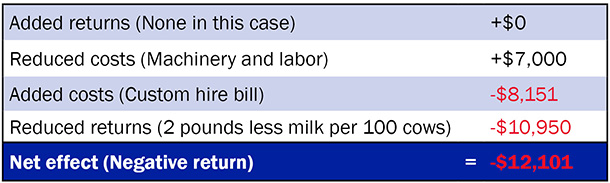

If the dairy goes to custom hire, they won’t have any costs associated with the harvest operation, such as equipment repairs, interest, insurance or depreciation. We can assume this saves $5,000. This number can vary wildly, so actual numbers should be substituted when possible.

In addition to zero machinery costs, labor costs may be lower, but this will likely be associated with the charge from the custom operator. We’ll say labor savings for the entire harvest season is around $2,000, bringing the total reduced cost to $7,000.

Step 4. List the added costs

This is where you enter the custom hire charge. We’ll assume the example dairy has 100 lactating cows and will need 600 tons of corn silage and 500 tons of haylage per year. Based on data from Michigan State University and Iowa State University, the average charge for chopping, hauling, and filling is $7.01 per ton for corn silage and $7.89 per ton for haylage for a total added cost of $8,151.

Step 5. List the reduced returns

Next, you’ll want to subtract the costs associated with a potential 2 pounds per cow decrease in milk production. How could this happen? The producer could be last on the custom operator’s list or the kernel processor may not be calibrated properly, so the dairy ended up with a bunker full of poorly processed feed. It can happen, and a 2-pound loss in milk production per 100 cows will cost $10,950.

Step 6. Summarize the net effect

If all goes well and this producer gains 2 pounds of milk per 100 cows, here’s what the partial budget could look like:

If things don’t go well and the dairy loses 2 pounds of milk per 100 cows, the partial budget could look like this:

Step 7. Consider non-economic factors (Intangibles)

With all decisions, you need to consider the non-economic factors, or intangibles. Ask yourself the following questions:

- Will this decision reduce stress because I won’t have the responsibility that comes with equipment ownership and operation, or increase stress because I have to rely on a custom operator?

- Am I convinced a custom operator can do a better job than myself?

- Do I love working with machinery?

- Do I hate working with machinery?

- Can I do a better job of animal husbandry if I don’t have to deal with harvest?

Conclusion

It’s clear from this exercise that a positive or negative impact on milk production and income needs to be the basis to answer the age-old question to hire a custom chopper or harvest it yourself. Think about the equation at the start of this article, Production – Cost = Profit. Cost is always important, but a change in production always has a far greater impact on profit.

For more tips, visit the Vita Plus website.