Hay dries in phases. In the first phase, moisture is lost pretty quickly through stomates (similar to the pores in our skin). This process dominates from the beginning moisture content of 80 percent or more down to about 60 percent moisture. At this moisture level, the stomates close and moisture has to leave the plant by other means. For this article, I will focus on just this initial phase of drydown.

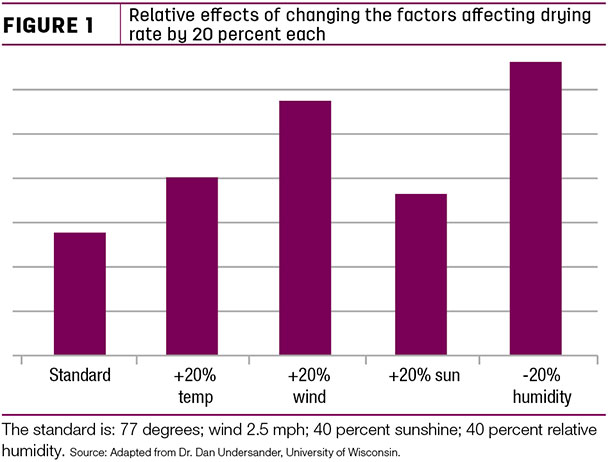

Figure 1 relates the relative impact of changing various factors involved in hay drying by 20 percent. This really shows which factors have the most impact on the process.

Humidity is the biggest, which makes sense because humidity is moisture. There are two aspects of humidity to consider: relative humidity as reported by the weatherman and humidity in the windrow.

Simply put, the lower the relative humidity, the faster and more completely hay will dry. As an example, at 60 percent relative humidity, hay cannot physically dry down past 16 percent, no matter how long it sits in the field. Now consider humidity inside the windrow.

Humidity inside the windrow starts at whatever the relative humidity is at cutting time but increases rapidly from moisture that leaves the plants but can’t get out of the windrow. The humidity inside a tight windrow climbs rapidly to around 95 percent or so.

The next factor in order of impact is wind speed. Imagine a moist layer of air hovering right around the windrow. This moisture has just left the plant. The more moist the air is right outside the plant stems and leaves, the more difficult it is for the remaining moisture to leave the plant.

Like many things in nature, water moves from an area of high concentration (inside the plant) to an area of low concentration (the atmosphere). What wind does is move the moisture that just escaped the plant away from the windrow. This air is replaced by more dry air, which can take more moisture from the hay.

Maybe you are like me – I was really shocked to learn increasing the temperature or increasing sun intensity didn’t have much effect on how quickly hay dries. Everything helps, of course, but when it comes to managing drydown time, our biggest impact will come from reducing humidity and utilizing wind to our advantage.

The number one factor for getting forage dry is exposure to sunlight. That may sound silly since I just said increasing the intensity of sunlight doesn’t have much effect. However, sunlight is more like a yes-or-no proposition. Without sunlight, hay won’t dry very fast.

But once we have some sun, it doesn’t really matter if it is partially cloudy or a bright blue sky. The reason has to do with all those stomates from the first paragraph. In a growing plant, stomates are open in the day and closed at night. Water vapor leaves the plant through these stomates.

As long as the plant is exposed to sunlight, and it has at least 60 percent moisture left, the stomates will be open, allowing water to evaporate out of the plant.

However, plants inside the windrow are in the dark. Their stomates are closed, trapping moisture inside the plant. It follows that the most important thing you can do management-wise is lay the swath out as wide as possible to expose as many of the plants to the sun as possible. When it comes to wind, wide windrows expose more of the plants to the wicking ability of the wind as well.

Windrows dry in layers, about an inch at a time. Once the top inch is dry, then the next inch will start to dry out. But if that second inch isn’t exposed to sunlight, it won’t dry nearly as fast. To maximize drying speed, consider turning or stirring the windrow so the bottom layer can then be exposed to sun.

We hesitate to disturb windrows because of leaf loss, but raking above 40 percent moisture really minimizes loss. Raking at 20 percent moisture is a disaster.

In good drying conditions, it will be time to rake just a few hours after cutting. Think about that in terms of machinery allocation and labor. If you put up hay by yourself, that means cutting for a few hours and then hopping on a rake or tedder for a while and then maybe back to cutting again. That is quite different from how most of us operate.

As a final thought, let’s address the equipment issue. What impact does our equipment have to do with this initial phase of drying hay? When we talk about wide swath, we mean as wide as possible with at least 80 percent of cutter bar width as the target.

You want the forage to pass straight through the machine hitting as few baffles and shields as possible, resulting in even windrows that will dry at a uniform rate as opposed to big slugs of hay lying next to each other to make a windrow. Some equipment brands are better at this than others.

Another thing we can do is adjust our stubble height a bit higher to keep the forage off the ground so it doesn’t wick soil moisture and air can flow under the windrows.

Notice there has been no discussion of conditioners at all. That is because conditioning doesn’t help in this phase of drying. Conditioning helps get that last bit of moisture out of the stems.

And finally, let’s address the elephant in the room when we talk about wide swathing: What about driving on windrows? If windrows are as wide as possible and you use a pull-type mower, you will drive on some or maybe all of them.

If you can adjust the width of the tires on the equipment, great. But if you will be coming back in a few hours to turn the hay, it won’t matter that you drove on it.

Getting hay below the 60 percent moisture level as quickly as possible can shave considerable time off the total drydown process, and it will lead to the best-quality hay possible. Keep that in mind this season, and I wish you all success on putting up high-quality hay this year. ![]()

PHOTO: Danny Shimfessel rakes hay to hasten drydown near Winchester, Kentucky. Photo by Lynn Jaynes.

-

Chad Hale

- Research and Acquisitions Manager

- Western Forage Resources

- Email Chad Hale