All forage harvesting systems are susceptible to dry matter losses, which result in higher costs through lost production and lower feed value.

The final stage of haymaking is hay storage. Round bales are susceptible to considerable dry matter losses due to weathering if not stored properly.

Storing feed with a moisture content in excess of 20 percent should be avoided. Excessive moisture in stored hay will result in heating and mold.

If hay is baled and stored at safe moisture levels, the main risk during storage is weathering, which is the removal of soluble nutrients by water moving over or through the bales.

The majority of weathering losses in round bales occur in the circumference of the round side of the bale.

The size of the bale has an impact on the proportion of the hay that is in the surface layer. Larger bales have less exposed surface as a percentage of total feed in the bale.

A round bale six feet in diameter will have 20 percent spoilage if the outer four inches of the circumference is weathered.

A five-foot bale will have 25 percent spoilage with a similar depth of weather damage around its circumference. In high-moisture conditions, it is possible to have up to eight inches of spoiled hay on the outside of a round bale.

Weathering of hay increases exponentially because spoiled hay is more easily penetrated by water. A round bale that has a wet layer does not shed water well and internal moisture levels increase.

Once a round bale gets wet, mold can develop. Moldy hay dries more slowly than unspoiled hay. Spoilage accelerates as the bale takes longer and longer to dry after a rain compared to an unspoiled bale.

To put the amount of water and potential spoilage that can occur with stored round bales into perspective, one inch of rain will leave approximately 22 gallons of water in a six-foot by six-foot round bale.

Weathering and spoilage accelerates when the round sides of two bales are in contact. This results in moisture being directed into and trapped in the bale – and can account for as much as 50 percent or more of storage losses.

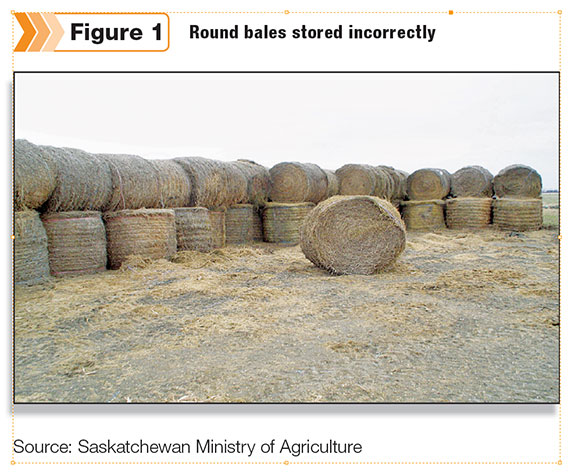

Storing bales with round sides touching should be avoided. Bales contacting damp soil draw up moisture (Figure 1).

As spoilage occurs, the bale flattens, increasing the surface area exposed to the damaging effects of damp soil.

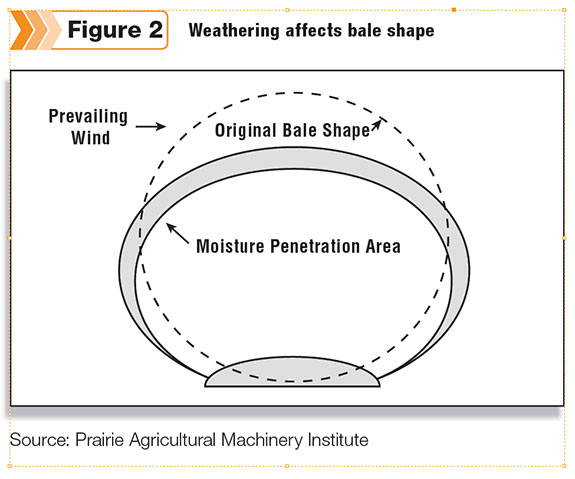

Flattening also reduces the angle of the top of the bale, increasing the bale’s exposure to moisture coming from above (Figure 2).

Dry matter losses can be reduced by wrapping bales in plastic, tarping or storing them in a hay shelter.

However, there are simpler and less expensive ways to reduce weathering.

Some of the most important factors that affect round bale storage losses are bale density, climatic conditions, storage site conditions, bale orientation, bale placement and level of protection of tops and bottoms of bales.

Increased bale density enhances the ability of round bales to shed water.

Even, uniform windrows make formation of consistently shaped and dense bales easier. Smaller windrows generally result in denser bales, as there are more layers per roll.

Finely textured grass bales shed water more effectively than coarsely textured hay. Mature forages, weedy hay and mature alfalfa allow more rapid infiltration of water due to large, hollow stems and increased bale porosity.

Wrapping the bale with twines closer together increases the ability of the bale to shed water but also increases baling costs and slows the baling process. Net wrap can reduce losses slightly but costs more than twine.

The nature of rainfall can impact spoilage. One large rain is less damaging than the same amount of rain received over an extended period. Warm, cloudy conditions increase spoilage rates in stored hay.

Round bale storage areas should be located as close to the feeding area as possible to minimize losses when moving weathered hay.

It is also important to choose an area with low flooding and fire risk. Choose a south-facing slope on well-drained soil to encourage solar drying and drainage of water away from stored bales.

Bales should be piled in single rows oriented north to south in order to maximize solar drying of hay.

Flat sides of bales should be butted tightly against each other to protect the ends and bottoms from getting wet. Rows should be at least three feet apart to allow for air circulation and sunlight penetration.

Round bales are economical and efficient to make but can be prone to dry matter losses during storage. Minimize losses by maximizing bale density and ensuring correct storage techniques. FG

—Excerpts from Crop Production News, Vol. 33, No. 6

Michel Tremblay

Provincial Forage Crops Specialist

Saskatchewan Ministry of Agriculture